Calculating DC-Link Capacitance for xEV Powertrains

This article is published by EEPower as part of an exclusive digital content partnership with Bodo''s Power Systems. There are many formulas to

Get a quote

Intermediate DC-Link Capacitor Reduction in a Two-Stage Cascaded AC/DC

In this paper, an innovative method to minimize the intermediate dc-link capacitance in a cascaded two-stage combination of a three-phase six-switch power factor correction

Get a quote

Comparison of three-phase three-level voltage source inverter

This study compares a three-phase three-level voltage source inverter with an intermediate dc–dc boost converter and a quasi-Z-source inverter in terms of passive

Get a quote

Selecting and Applying DC Link Bus Capacitors for Inverter

In this paper, we will discuss how to go about choosing a capacitor technology (film or electrolytic) and several of the capacitor parameters, such as nominal capacitance, rated ripple current,

Get a quote

Comparison of three-phase three-level voltage source

1 Introduction Many topologies of inverters with intermediate dc–dc boost converters have been developed [1 - 5]. These include converters built

Get a quote

(PDF) Current Source Inverter (CSI) Power

PDF | Grid converters play a central role in renewable energy conversion. Among all inverter topologies, the current source inverter (CSI)

Get a quote

How does a DC link work What is its purpose

How does a DC link work What is its purpose ? A DC link, in the context of power electronics and variable frequency drives (VFDs), refers to a crucial component that connects

Get a quote

PWM control of a 5-level single-phase current-source inverter with

Print ISSN: 0275-9306 Electronic ISSN: 2377-6617 INSPEC Accession Number: Persistent Link: https://ieeexplore.ieee /servlet/opac?punumber=11209 More » Publisher: IEEE

Get a quote

High-Bandwidth Phase Current and DC-Link Voltage

This reference design reduces system cost and enables a compact design for isolated phase current and DC-Link voltage measurement in three-phase inverters, while achieving high

Get a quote

Modulation and control scheme for DC-link current minimization

To address this issue, the topology of CSI is improved, and a modulation scheme without additional losses is proposed in this paper to control the DC-link current.

Get a quote

What is a DC link

A DC link is a connection which connects a rectifier and an inverter. These links are found in converter circuits and in VFD circuits. The AC supply of a specific frequency is converted into

Get a quote

Advantages of an integrated DC link reactor

FSF and SINAMICS G120X, FSA to FSG have an LDC reactor integrated in the DC link; half of the inductance is in the positive arm of the DC link and the other half in the negative arm of the

Get a quote

What Is A DC Bus In A VFD? | VFD Internal Power Explained

A DC bus in a VFD is the internal link between the rectifier and inverter sections. It stores and delivers filtered DC voltage, enabling efficient variable motor speed control.

Get a quote

The Essence of Three-Phase AC/AC Converter Systems

Abstract—In this paper the well-known voltage and current DC-link converter systems, used to implement an AC/AC converter, are initially presented. Using this knowledge and their space

Get a quote

The strategy of second harmonic voltage match suppression for the DC

1. Introduction In the two-stage single-phase inverter, the second harmonic current with twice output voltage frequency exists in the former DC converter because the

Get a quote

Cycloconverter: Applications & Types

A cycloconverter achieves this through synthesizing the output waveform from segments of the AC supply (without an intermediate DC link). The main forms of electrical

Get a quote

Current Source Inverter (CSI) Power Converters in

Grid converters play a central role in renewable energy conversion. Among all inverter topologies, the current source inverter (CSI)

Get a quote

LOOKING CLOSER AT DC LINK CAPACITORS IN

Another EV subsystem where DC link capacitors are found is the inverter in motor drive circuits (shown in Figure 3). The inverter converts DC power from the battery to three-phase AC

Get a quote

DC-LINK Capacitors / Intermediate Circuit Capacitors

WIMA DC-Link intermediate circuit capacitors are designed for applications in high power converter technology where due to increasing electrical requirements they are more and more

Get a quote

How do I calculate the DC link current of a three

The DC link current Idc of the inverter can be calculated from electrical analysis of the inverter. If your active output power is Po= 3 IphVph cos phi and the

Get a quote

6 FAQs about [Current inverter intermediate DC link]

How to calculate dc link current IDC?

The DC link current Idc of the inverter can be calculated from electrical analysis of the inverter. If your active output power is Po= 3 IphVph cos phi and the conversion efficiency is Eta, then the input DC power Pi= IdcVdc= Po/Eta. If Vdc is known one can can get Idc. Vdc is normally =sqroot 2 Vph. Best wishes

What is a DC link?

A DC link is a connection which connects a rectifier and an inverter. These links are found in converter circuits and in VFD circuits. The AC supply of a specific frequency is converted into DC. This DC, in turn, is converted into AC voltage. The DC link is the connection between these two circuits.

What is DC link voltage?

DC link voltage: This is the voltage that prevails in DC links. This voltage fluctuates due to the continuous input and output of energy and is adjusted in each case by means of the adjacent converters. DC link capacitor: This is the actual energy storage device. Pre-charging circuit: In a DC link, this circuit consists of electrical resistors.

What is a DC link capacitor?

The AC supply of a specific frequency is converted into DC. This DC, in turn, is converted into AC voltage. The DC link is the connection between these two circuits. The DC link usually has a capacitor known as the DC link Capacitor. This capacitor is connected in parallel between the positive and the negative conductors.

Why does a DC link capacitor have a ripple current ICAP?

We may infer from Figure 2 that the DC link capacitor’s AC ripple current Icap arises from two main contributors: (1) the incoming current from the energy source and (2) the current drawn by the inverter. Capacitors cannot pass DC current; thus, DC current only flows from the source to the inverter, bypassing the capacitor.

What is high-bandwidth phase current & DC-link voltage sensing reference design?

High-Bandwidth Phase Current and DC-Link Voltage Sensing Reference Design (Rev. A) This reference design reduces system cost and enables a compact design for isolated phase current and DC-Link voltage measurement in three-phase inverters, while achieving high bandwidth and sensing accuracy.

Guess what you want to know

-

High frequency pulse DC link inverter

High frequency pulse DC link inverter

-

How much current does the DC inverter provide

How much current does the DC inverter provide

-

12v inverter 3kw working current

12v inverter 3kw working current

-

Inverter power supply connected to DC

Inverter power supply connected to DC

-

Inverter fixed DC voltage control

Inverter fixed DC voltage control

-

Lithuania DC power inverter

Lithuania DC power inverter

-

What is the DC side resistance of the inverter

What is the DC side resistance of the inverter

-

Inverter voltage outer loop current inner loop

Inverter voltage outer loop current inner loop

-

How much current does a 2200 watt inverter draw when connected to 12v

How much current does a 2200 watt inverter draw when connected to 12v

-

Three-phase inverter DC voltage

Three-phase inverter DC voltage

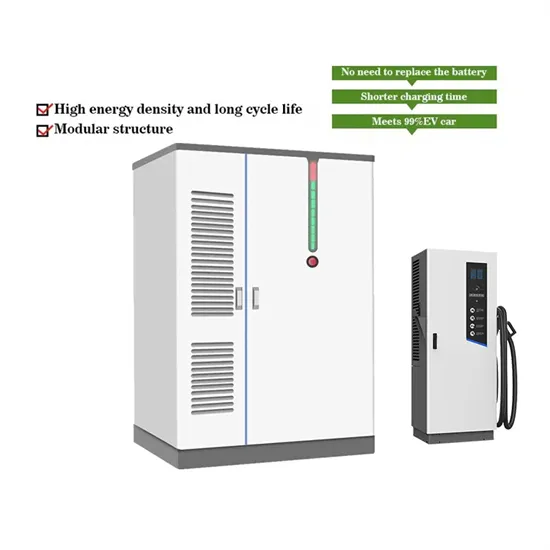

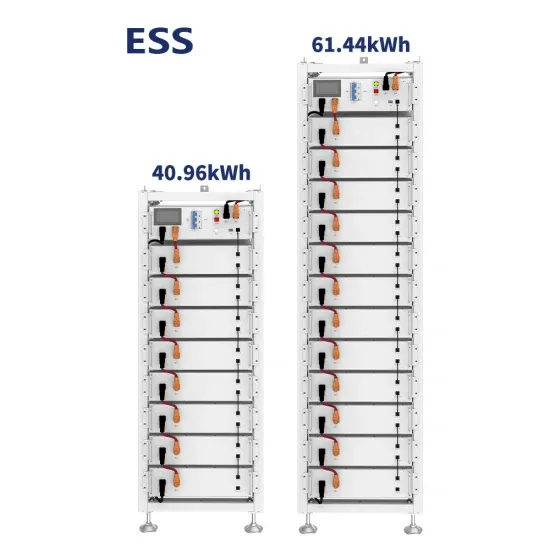

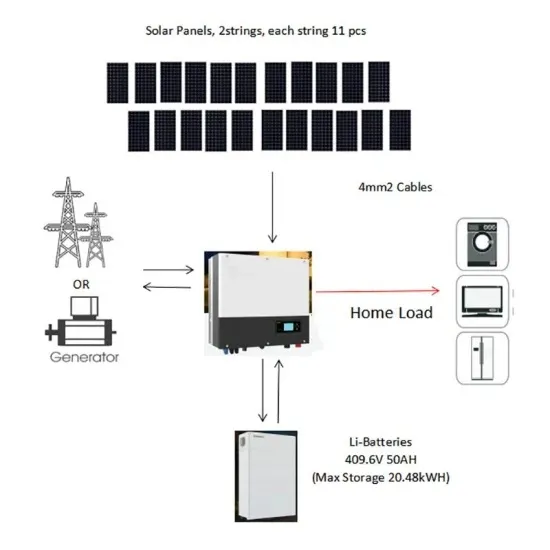

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.