How much power does an inverter draw?

So a 1500 watt inverter with a 500 watt load would be 50 (25) Amps, not 150 (75) Amps. The same inverter with a 1200 Watt load would draw 120 (60) Amps, which would be the same

Get a quote

Inverter Current Calculator

Click "Calculate" to find out the current the inverter will draw from the battery or DC power source. This calculated current is essential for battery selection, cable sizing, and protecting your

Get a quote

Inverter Calculator

Power consumption is rated either in wattage or amperes, and information regarding the required "watts" or "amps" generally is stamped or printed on

Get a quote

How Much Power Does My Inverter Use? | Offroad Living

Calculate how much power your inverter uses with this simple guide. Discover best practices when it comes to preserving your inverter''s power.

Get a quote

How much current does a 12v inverter require

In general, a 1500 Watt inverter running on a 12V battery bank can draw as much as 175 Amps of current. A 1500W inverter running on a 24V battery bank can draw up to 90 Amps of current. If

Get a quote

How much current does a 12V inverter draw?

A 1000 watt load on a 1000 watt 12V inverter draws 100 to 110 amps, depending on the inverter efficiency. On a 24V setup, the same 1000 watt load will draw 40 to 60 amps.

Get a quote

How Many Amps Does a 2000W Inverter Draw?

Click "Calculate" to find out the current the inverter will draw from the battery or DC power source. This calculated current is essential for battery selection, cable sizing, and protecting your

Get a quote

How much power does an inverter draw?

How much current is drawn from a 12V or 24V battery when running a battery inverter? Documented in this article are common questions relating to the inverter draw (inverter amp

Get a quote

How much power does an Inverter use just sitting there idling?

Cycling power from batteries to inverter would be repeating that current surge into capacitors. High temperature (within spec) burn-in of electronics never did much to improve

Get a quote

Inverter Calculator

Power consumption is rated either in wattage or amperes, and information regarding the required "watts" or "amps" generally is stamped or printed on most appliances and equipment. If this

Get a quote

How Many Amps Does a 2000W Inverter Draw?

In this example, 2000 watts an hour divided by 12 volts equals 166.6 amps. The following calculations assume you have a high quality inverter that can draw maximum power. If not, we

Get a quote

Inverter AC to DC Amperage Conversion Calculator

Our AC amps to DC amps conversion calculator can help you convert electric currents from an alternating current (AC) to a direct current

Get a quote

Inverter Current Calculator, Formula, Inverter Calculation

Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the load, the input voltage to the

Get a quote

What Size Wire For Any Inverter: Inverter Wire Size

Using a 750 watt power inverter you can use a 6 AWG cable for 10ft or less. This is due to the fact that you will be drawing a maximum of 750 watts at 12 volts

Get a quote

How much power does an inverter use on standby – PowMr

The no-load current draw of an inverter is the amount of current that the inverter consumes when it is connected to a power source but there is no load (i.e., no device or

Get a quote

HOW MUCH CURRENT IS DRAWN FROM THE 12V

When looking at the power rating on inverters its crucial to look at the maximum input current / Watts (not output Watts) as they will consume

Get a quote

How much current can drive a 12v inverter

In general,a 1500 Watt inverter running on a 12V battery bank can draw as much as 175 Ampsof current. A 1500W inverter running on a 24V battery bank can draw up to 90 Amps of current. If

Get a quote

Inverter Amp Draw Calculator

Inverters with a greater DC-to-AC conversion efficiency (90-95%) draw fewer amps, whereas inverters with a lower efficiency (70-80%) draw more current. Note: The results

Get a quote

What Size Wire For Any Inverter: Inverter Wire Size

To work out amps you use the formula – watts ÷ volts = amps. For example, if you''re using a 2000 watt inverter with 12V input it would be 2000W ÷ 12V =

Get a quote

What Size Wire For Any Inverter: Inverter Wire Size Chart

Using a 750 watt power inverter you can use a 6 AWG cable for 10ft or less. This is due to the fact that you will be drawing a maximum of 750 watts at 12 volts which results in 62.5 amps.

Get a quote

How Many Amps Does a 600 Watt Inverter Draw?

A 12V 100ah battery can run a fully loaded 600 watt inverter in just under two hours. 600 watts equals 50 amps (W / V = A). The load draws 50 amps an hour so it should last two hours.

Get a quote

Inverter Current Calculator & Formula Online Calculator Ultra

Calculating the current draw of an inverter is essential in designing and troubleshooting electrical and electronic systems. This process ensures compatibility with

Get a quote

6 FAQs about [How much current does a 2200 watt inverter draw when connected to 12v ]

How many amps does a 12V 2000W inverter draw?

A 12V 2000W inverter running at maximum load draws 166.6 amps an hour. Divide the watts consumed per hour by the voltage and you get the amps. In this example, 2000 watts an hour divided by 12 volts equals 166.6 amps. The following calculations assume you have a high quality inverter that can draw maximum power.

How much power does a 12 volt inverter use?

Power conversion losses from converting 12v DC battery power to 230v AC mains power in an inverter uses about 10% more power than the actual appliance draws, so expect around a 1540w draw from the battery (1400w x 1.1 = 1540w). Assuming a cup of coffee takes about a minute to make: 1540w / 12 volts = 128 Amps

What is the maximum current drawn by a 1500 watt inverter?

The maximum current drawn by a 1500-watt inverter is influenced by the following factors: Maximum Amp Draw for 85%, 95% and 100% Inverter Efficiency A. 85% Efficiency Let us consider a 12 V battery bank where the lowest battery voltage before cut-off is 10 volts. The maximum current is

How many amps does a 1200 watt inverter draw?

The same inverter with a 1200 Watt load would draw 120 (60) Amps, which would be the same amount as a 1200 Watt inverter at load capacity. And for a 2000w 12v pure sine wave inverter? We think you get the picture. The 2000 watt inverter amp draw depends on its watt load.

How many amps does a 3000W inverter draw?

Inverter Current = 1000 ÷ 12 = 83.33 Amps So, the inverter draws 83.33 amps from a 12V battery. Inverter Current = 3000 ÷ 24 = 125 Amps So, a 3000W inverter on a 24V system pulls 125 amps from the battery. Inverter Current = 5000 ÷ 48 = 104.17 Amps The current drawn is approximately 104.17 amps.

How many amps do inverters draw?

Inverters with a greater DC-to-AC conversion efficiency (90-95%) draw fewer amps, whereas inverters with a lower efficiency (70-80%) draw more current. Note: The results may vary due to various factors such as inverter models, efficiency, and power losses. Here is the table showing how many amps these inverters draw for 100% and 85 % efficiency.

Guess what you want to know

-

How much current does a 3 watt solar panel draw

How much current does a 3 watt solar panel draw

-

How much current does a 6 watt solar panel draw

How much current does a 6 watt solar panel draw

-

12v inverter 3kw working current

12v inverter 3kw working current

-

12v 300 watt inverter

12v 300 watt inverter

-

How long can a 12v 100ah inverter last

How long can a 12v 100ah inverter last

-

How much power does a 10 million watt inverter have

How much power does a 10 million watt inverter have

-

How many amps does a 12v inverter require

How many amps does a 12v inverter require

-

60V inverter connected to 12v

60V inverter connected to 12v

-

How big of an inverter can a 12v 45AH power supply be

How big of an inverter can a 12v 45AH power supply be

-

How many hours can a home inverter convert 12v to 220v be used for

How many hours can a home inverter convert 12v to 220v be used for

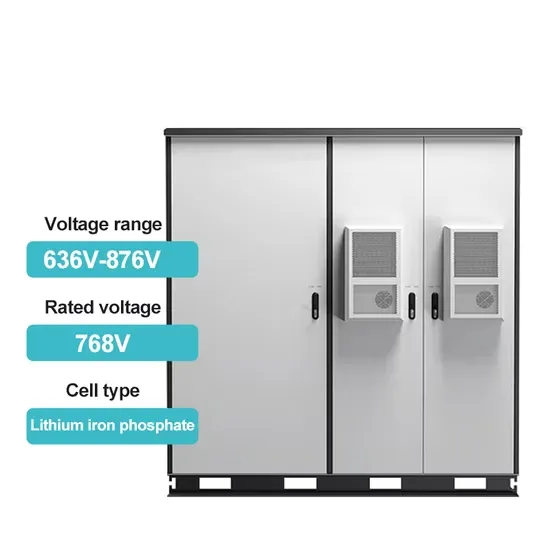

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.