What Inverter Size Do I Need to Run a Laptop?

How Much Power Does a Laptop Computer Use? Power consumption depends on several factors, the most important being the specs, the type and how you use it. The most portable

Get a quote

Inverter Size Calculator

Inverter Size (W) = (Total Wattage × Safety Factor) ÷ Inverter Efficiency. This ensures that the inverter can handle both the load and the efficiency losses. Let''s walk through a simple

Get a quote

Unveiled! the truth about inverter acs: how many watts do they

In the sweltering heat, air conditioners have become indispensable appliances, providing respite from the scorching temperatures. Among the various types of air conditioners

Get a quote

What Size Inverter Do I Need?

Learning how to calculate inverter size for your needs can be a tricky task, especially if you''re unfamiliar with how an inverter works or how much power you need to produce.

Get a quote

How Much Does a Solar Inverter Cost?

🏠 Solar Inverters Cost How Much Does a Solar Inverter Cost? Solar inverters vary quite a bit in price. Micro inverters can start as low as $195 apiece. String inverters can vary from $500 to

Get a quote

How Much Power Does Solar Inverter Use and How to Create the

Learn how much power a solar inverter uses and get practical tips on designing the ideal solar power project. From understanding inverter efficiency to system sizing, this

Get a quote

How much power does an inverter use on standby –

For a 1000W inverter, the average idle power consumption could be around 10-20 watts, while for a 2000W inverter, it could be around 20-40

Get a quote

What Size Inverter Do I Need?

Inverter Size Calculator Learning how to calculate inverter size for your needs can be a tricky task, especially if you''re unfamiliar with how an inverter works or

Get a quote

What Size Inverter Do I Need?

Learning how to calculate inverter size for your needs can be a tricky task, especially if you''re unfamiliar with how an inverter works or how much power

Get a quote

How Many Solar Panels Produce 1 MW?

Given that the sum of the inverters wattage is one MW, we can work backwards to figure out the total number of panels necessary to complete a system of this design. One MW is equal to

Get a quote

Inverter Efficiency: Understanding How Much Power You''re

Most modern inverters have efficiency ratings between 90% and 98%. Let''s break it down: If you feed 1000 watts of DC power into your inverter and it outputs 950 watts of AC

Get a quote

Inverter Amp Draw Calculator

It determines how many devices you can power and how long your inverter can function. In this article, let''s explore the inverter amp draw calculator for 1000W, 1200W, and

Get a quote

Inverter Power Draw: How Much Power Does an Inverter Use

Calculate the input power: Use the formula: Input Power (Watts) = Output Power (Watts) / Efficiency. For example, if your inverter outputs 1000 watts at 90% efficiency, the

Get a quote

How Much Does A Solar Inverter Cost? [Updated: April 2025]

Solar inverters typically cost between $1000 and $1500 for an average-sized installation. However, as the size of the installation increases, so does the cost of the inverter. For

Get a quote

How much does a solar inverter cost per watt? | NenPower

1. The cost of a solar inverter typically falls between $0.10 and $0.50 per watt, influenced by factors such as the inverter type, brand reputation, and installation specifics. The

Get a quote

How Much Power Does An Inverter Draw With No Load?

How much power an inverter uses is not determined by its watt rating. To know the power consumption, you need to add a percentage to the power used by a load according to

Get a quote

How Many Amps Does a 1000 Watt Inverter Draw?

But how many amps does a 1000 watt inverter use? Is your inverter large enough for your system amp requirements? Or do you have to buy a larger system? A 1000 watt load on a 1000 watt

Get a quote

Inverter Power Calculator & Formula Online Calculator Ultra

This calculator streamlines the process of estimating the effective AC power output of an inverter, making it easier for individuals and professionals to plan and implement

Get a quote

The Only Inverter Size Chart You''ll Ever Need

It determines how many devices you can power and how long your inverter can function. In this article, let''s explore the inverter amp draw

Get a quote

What Can You Run on a 1000-Watt Inverter?

Conclusion: Is a 1000-Watt Inverter Right for You? In conclusion, a 1000-watt inverter is a fantastic option for those looking to power smaller devices and appliances on the go. Whether

Get a quote

BMS amp rating and available watts with an Inverter

If I have a 1 million amp 12v battery and a 100K watt inverter (so I have plenty of battery and inverter capacity) but my BMS is 50 amps, is this true? 50amps * 12 volts = 600

Get a quote

What Will An Inverter Run & For How Long? (With

So I''m gonna explain to you guys in simple words about what you can run on your any size inverter and what are the key point to keep in mind.

Get a quote

What Will An Inverter Run & For How Long? (With Calculator)

So I''m gonna explain to you guys in simple words about what you can run on your any size inverter and what are the key point to keep in mind. And also how long your inverter

Get a quote

How Much Power Does An Inverter Draw With No Load?

How much power an inverter uses is not determined by its watt rating. To know the power consumption, you need to add a percentage to the

Get a quote

6 FAQs about [How much power does a 10 million watt inverter have ]

How much power does an inverter use?

But this amount may vary depending on the type of battery bank used and the types of loads connected to the inverter. Typically, in a no-load current, the energy drawn by the inverter is only 2 to 10 watts an hour. What Amount of Power is Wasted by Inverter? Do not confuse the inverter’s no-load current with the efficiency rating of the inverter.

How many Watts Does a 10 watt inverter use?

For example, sometimes a radio connected to the inverter uses just 5 watts but the inverter itself consumes 10 watts. This is a complete waste of money and energy. Secondly, accumulation of no current load like imagine your inverter is left on 24 by 7. Now, with a 10-watt no-power draw rating, it is almost 70 watts per week that will be wasted.

How to calculate inverter power?

The inverter power calculation formula is given by: Pi = \frac {RP \times E} {100} P i = 100RP ×E where: E E is the Efficiency in percent. Consider an inverter with a rated power of 500 watts and an efficiency of 90%. The inverter power can be calculated as: Pi = \frac {500 \times 90} {100} = 450 \text { watts} P i = 100500× 90 = 450 watts

How many watts can a 3000-watt inverter run?

A rule of thumb is that the total output load should be less than the inverter capacity. For example, if you have a 3000-watt inverter you can run up to 2500 watts of output load with it. As I have mentioned earlier you have to keep in mind the efficiency rate of your inverter before putting the load on it. That is all you need to know.

How much power does a 450 watt inverter produce?

An inverter with an efficiency of 90% provides an output power of 450 watts (W). Calculate the rated power of the inverter. Given: P i (W) = 450W, E = 90%. Inverter power, P i (W) = RP (W) * E / 100 RP (W) = P i (W) * 100 / E RP (W) = 450 * 100 / 90 RP (W) = 500W.

How many watts in a 24V inverter?

Power drawn = 24V * 0.4 = 9.6 watts This formula and calculation are applicable to all inverters irrespective of their size. 12V or 24V is the only thing that will make the difference in the power consumed. Remember, the higher the voltage is the greater the no-load current will be.

Guess what you want to know

-

How much power inverter should a household buy

How much power inverter should a household buy

-

How much does it cost to store energy per watt for wind power

How much does it cost to store energy per watt for wind power

-

How much current does a 2200 watt inverter draw when connected to 12v

How much current does a 2200 watt inverter draw when connected to 12v

-

How big of an appliance can a 12v 600w inverter power

How big of an appliance can a 12v 600w inverter power

-

How much does a solar power station water pump inverter cost

How much does a solar power station water pump inverter cost

-

How big a water pump inverter should I buy for solar power

How big a water pump inverter should I buy for solar power

-

How much power does a 10KW inverter have

How much power does a 10KW inverter have

-

How big of an inverter can a 12A 48V battery power

How big of an inverter can a 12A 48V battery power

-

How much does it cost per watt for solar grid-connected power generation

How much does it cost per watt for solar grid-connected power generation

-

How much does one watt of energy storage power station cost

How much does one watt of energy storage power station cost

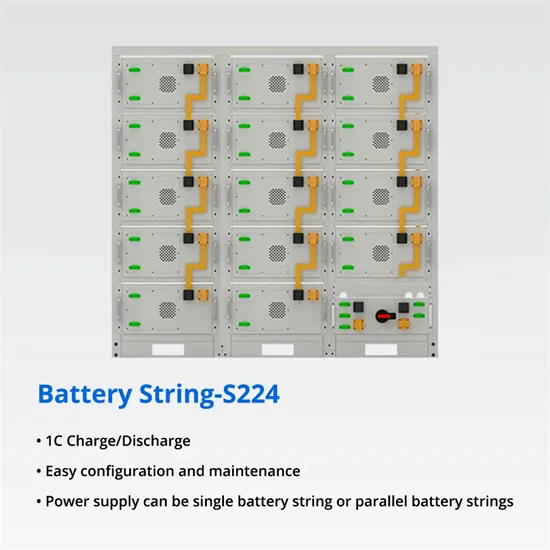

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.