Voltage Source Inverters Control using PWM/SVPWM For

In this method, a fixed dc input voltage is given to the inverter and a controlled ac output voltage is obtained by adjusting the on and off periods of the inverter components.

Get a quote

Frequency inverters | Explanation, function & design

In addition, a frequency inverter can control the direction of rotation, e.g. for synchronous motors in elevator technology. In terms of static frequency inverters, a distinction is drawn between

Get a quote

Voltage Control Using Inverter Reactive Power Control

In this post, we''ll look at four reactive power control modes that can be selected in modern smart inverters to control inverter reactive power production (or absorption) and

Get a quote

Design of an improved PWM inverter using PI controller

A voltage source inverter (VSI) is one that takes in a fixed voltage from a device, such as a DC power supply, and converts it to a variable-frequency AC supply.

Get a quote

Optimal Structures for Voltage Controllers in Inverters

In this paper, we pose an optimal voltage control problem for ac inverter systems and study the structure of the resulting feedback laws.

Get a quote

JETIR Research Journal

Abstract: Voltage source inverters (VSIs) are key components in numerous power electronic systems, enabling the efficient conversion of DC power to AC power with variable voltage,

Get a quote

Flexible control strategy for HVDC transmission system adapted

The control mode of the inverter can be mainly divided into fixed-extinction angle control and fixed-DC voltage control [23]. If the inverter station adopts the fixed- extinction

Get a quote

HowTo: How an Inverter Drive Works and Controls the Speed of

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get a quote

Voltage Control Methods of Inverter – PWM Technique

When the available input voltage source is dc, the inverter''s input voltage can be controlled by using a chopper. The block diagram for controlling the output voltage of the

Get a quote

Voltage Source Inverter Reference Design (Rev. E)

This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU). The design supports two modes of operation for the inverter: a voltage

Get a quote

Power Inverter vs. Frequency Inverter | inverter

Conclusion Power inverter: Converts DC to AC, typically without changing the frequency. Used for providing AC power from DC sources. Frequency inverter: Converts AC to

Get a quote

DC-to-AC Converters (Inverters): Design, Working &

The electrical circuits that transform Direct current (DC) input into Alternating current (AC) output are known as DC-to-AC Converters or

Get a quote

Technical White Paper SolarEdge Single Phase Inverter

Inverters The SolarEdge inverters employ a very high efficiency single-stage conversion, transformer-less topology. The SolarEdge inverter includes an independent voltage control

Get a quote

Power Converters: Frequency Converters, Inverters,

Function: Frequency converters control AC power frequency, while inverters convert DC to AC. Output: Frequency converters provide variable AC

Get a quote

How does an inverter control current?

This is the same way that typical home electricity works -- the source is specified to provide a particular voltage and makes no attempt to control the current that flows through the

Get a quote

Voltage Control Methods of Inverter – PWM Technique

2.1 Introduction The dc-ac converter, also known as the inverter, converts dc power to ac power at desired output voltage and frequency. The dc power input to the inverter is obtained from an

Get a quote

CHAPTER 2

2.1 Introduction The dc-ac converter, also known as the inverter, converts dc power to ac power at desired output voltage and frequency. The dc power input to the inverter is obtained from an

Get a quote

Voltage Control Using Inverter Reactive Power Control

In this post, we''ll look at four reactive power control modes that can be selected in modern smart inverters to control inverter reactive power

Get a quote

Maximum power extraction and DC-Bus voltage regulation in grid

As a result, if the inverter''s capacitance fails to meet the principle in Eq. (6), the system conditions, with the DC-Bus voltage, become unbalanced or fluctuating. As a result,

Get a quote

AKX00057-1

In order to control the output voltage supplied to a motor, the DC voltage fed to the inverter is varied by a voltage booster. To rotate a motor at low RPM, the DC voltage is set to

Get a quote

Current-Controlled Voltage Source Inverter

A current-controlled voltage source inverter (CCVSI) is defined as a type of inverter that operates as a current source, allowing for fast response in power flow control by adjusting the switching

Get a quote

Application Note How to Toggle SolarEdge Commercial

Overview – How to enhance your design with S1200 Power Optimizers With firmware 4.17 and above, you will be able to toggle your SolarEdge commercial inverter settings from 750Vdc to

Get a quote

Application Note: SolarEdge Fixed String Voltage, Concept

In an independent process, the power optimizers enable the inverter to automatically maintain a fixed string voltage, at the optimal point for DC-AC conversion by the inverter, regardless of

Get a quote

Voltage Control Techniques for Inverters | EEEGUIDE

A combination of a diode rectifier and a dc chopper is used for varying the dc link voltage. Closed loop control in this case changes the time ratio of the chopper.

Get a quote

6 FAQs about [Inverter fixed DC voltage control]

How to control the output voltage of an inverter?

When the available input voltage source is dc, the inverter’s input voltage can be controlled by using a chopper. The block diagram for controlling the output voltage of the inverter when the input voltage available is constant is of constant DC type is shown below.

What is voltage control of inverter?

Voltage control of inverters is employed in order to compensate for changes in input dc voltage. Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter.

How do you control a power inverter?

external control circuitry is required. The most efficient method of doing this is by Pulse Width Modulation (PWM) control used within the inverter. In this scheme the inverter is fed by a fixed input voltage and a controlled ac voltage is obtained by adjusting the on and the off periods of the inverter components.

What is a motor control inverter?

In motor control applications, inverters handle the control of circuit voltage along with frequency so that the saturation of motor magnetic circuits is avoided. In the case of variable speed drives, inverters with voltage control help in achieving voltage variation.

What is a DC link inverter?

The filter capacitor across the input terminals of the inverter provides a constant dc link voltage. The inverter therefore is an adjustable-frequency voltage source. The configuration of ac to dc converter and dc to ac inverter is called a dc- link converter. source inverters. A voltage–fed inverter (VFI) or more generally a voltage–source

What is internal control of inverter?

Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage. The block diagram representation of this method is shown in the below figure.

Guess what you want to know

-

Inverter DC side rated voltage

Inverter DC side rated voltage

-

Mauritania inverter DC voltage wholesale

Mauritania inverter DC voltage wholesale

-

Photovoltaic inverter DC voltage exceeds 600V

Photovoltaic inverter DC voltage exceeds 600V

-

Ultra-high voltage DC inverter

Ultra-high voltage DC inverter

-

DC panel inverter input voltage

DC panel inverter input voltage

-

Inverter DC maximum voltage

Inverter DC maximum voltage

-

Inverter intermediate DC voltage

Inverter intermediate DC voltage

-

270v high voltage DC to 220v inverter

270v high voltage DC to 220v inverter

-

Voltage closed loop control of inverter

Voltage closed loop control of inverter

-

Can an inverter increase DC voltage

Can an inverter increase DC voltage

Industrial & Commercial Energy Storage Market Growth

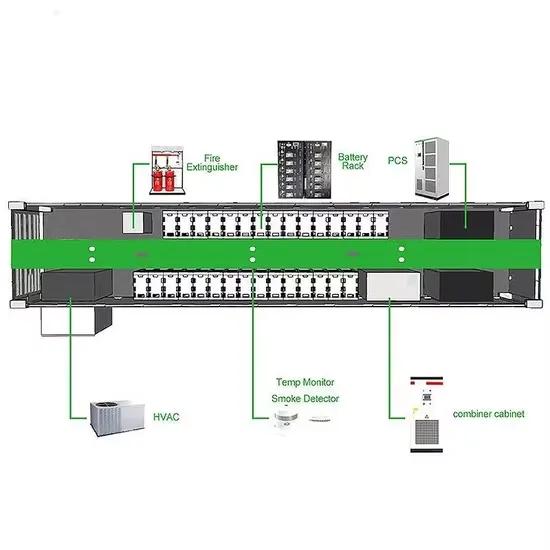

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.