Intelligent Robust Control Design with Closed-Loop Voltage

High-performance UPS inverters prevent IoT devices from power outages, thus protecting critical data. This paper suggests an intelligent, robust control technique with closed

Get a quote

Closed‐loop control of a single‐stage switched‐boost inverter in

It introduces a novel approach closed-loop control technique to overcome most of the inverter drawbacks. Also, it enhances both the DC-link and the transformer-less rated AC

Get a quote

Closed‐loop waveform control of boost inverter

In this paper, the closed-loop performance of a proposed waveform control method to eliminate such a ripple current in boost inverter is

Get a quote

Voltage Control Techniques for Inverters | EEEGUIDE

A closed loop control varies the firing angle depending upon the frequency. The function generator (Fig. 3.97) gives a relation between the stator frequency

Get a quote

Design of Closed-Loop Control of a Three-Phase Sine Wave

In this paper, a high gain DC–DC converter is implemented in order to convert the voltage obtained from solar cells to a high voltage at desirable limit and it will optimize low

Get a quote

Frequency and Voltage Control Schemes for Three-Phase Grid

We show that the proposed control architectures achieve both power sharing without a communication link, and desirable passivity properties that can enhance the dynamic

Get a quote

Synchronized SVPWM schemes for closed-loop current control of

The modulation index fluctuates when a closed-loop current control system is used to control the motor winding current. In addition, the angle of the voltage vector output from the

Get a quote

Design of Closed-Loop Control of a Three-Phase Sine Wave Inverter

In this paper, a high gain DC–DC converter is implemented in order to convert the voltage obtained from solar cells to a high voltage at desirable limit and it will optimize low

Get a quote

Open-Loop and Closed-Loop Control

This figure shows an open-loop control system. The power circuit consists of a PWM voltage fed inverter supplied by a DC source. The system does not use

Get a quote

Current Regulated Voltage Source Inverter | CLosed

Although Current Regulated Voltage Source Inverter operates as a CSI, it does not use large dc inductor and filter capacitors, hence it has lower weight,

Get a quote

Intelligent Robust Control Design with Closed-Loop

High-performance UPS inverters prevent IoT devices from power outages, thus protecting critical data. This paper suggests an intelligent,

Get a quote

A Simulink-Based Closed Loop Current Control of Photovoltaic Inverter

The proposed system overcomes these critical issues by using a closed loop current control, resulting in an alternating current (AC) output of constant frequency and

Get a quote

A research on closed-loop control strategy for single-phase

In this study, a control strategy combining the three closed-loop control with an iterative-based RMS algorithm is proposed for addressing the voltage drop and slow response problems of

Get a quote

Closed‐loop control of a single‐stage switched‐boost

It introduces a novel approach closed-loop control technique to overcome most of the inverter drawbacks. Also, it enhances both the DC-link

Get a quote

Stand-alone three phase sine pwm inverter control in D-Q

The closed loop control is implemented in synchronous reference frame, by converting three phase quantities in d-q synchronous reference frame. The inverter is fed by a

Get a quote

Current Regulated Voltage Source Inverter | CLosed Loop Control

Although Current Regulated Voltage Source Inverter operates as a CSI, it does not use large dc inductor and filter capacitors, hence it has lower weight, volume and cost and faster dynamic

Get a quote

Voltage Control Techniques for Inverters | EEEGUIDE

A closed loop control varies the firing angle depending upon the frequency. The function generator (Fig. 3.97) gives a relation between the stator frequency and applied voltage to the

Get a quote

V/F Control: Open and Closed Loop V/F Control

Closed Loop V/F Control The basis of constant V/F speed control of induction motor is to apply a variable magnitude and variable frequency voltage to the

Get a quote

Loop Power Control

Loop power control refers to the external power control mechanism that regulates the frequency and inverter output voltage based on the droop characteristics for real and reactive power,

Get a quote

Fundamentals of Current and Voltage control loops for

5. Once you have designed your inverter for grid connected mode, now remove the grid and make an outer voltage control loop for your inverter. 6. Repeat

Get a quote

Implementation of closed loop control technique for

trategy of the inverter must guarantee its output waveforms to be sinusoidal with fundamental harmonic. For this purpose, close loop current control strategies such as H∞ repetitive

Get a quote

Block diagram of an inverter with closed-loop voltage

Download scientific diagram | Block diagram of an inverter with closed-loop voltage feedback control. from publication: Instantaneous Current-Sharing

Get a quote

Modelling, control design, and analysis of the inner

In voltage-controlled voltage source inverters (VSIs)-based microgrids (MGs), the inner control is of prime interest task for guaranteeing

Get a quote

Single Phase Transformerless Inverter and its Closed Loop

The inverter control in single stage becomes more complicated to achieve objectives such as MPPT, Grid Synchronization and closed loop current control. Double stage systems include

Get a quote

Closed-Loop Voltage Control for Maximizing Inverter Output

In this article, a closed-loop voltage control method is developed based on the d -axis reference current to maximize the voltage extraction from dc-link voltage while minimizing

Get a quote

Closed-Loop Voltage Control for Maximizing Inverter Output Voltage

In this article, a closed-loop voltage control method is developed based on the d -axis reference current to maximize the voltage extraction from dc-link voltage while minimizing

Get a quote

Three-phase inverter closed-loop control based on SVPWM drive

This paper innovatively uses script module programming of plecs software to build the SVPWM modulation module which drive the three-phase inverter while realizing the closed

Get a quote

Guess what you want to know

-

Single voltage closed loop inverter

Single voltage closed loop inverter

-

Inverter fixed DC voltage control

Inverter fixed DC voltage control

-

Low voltage inverter control cabinet implementation standards

Low voltage inverter control cabinet implementation standards

-

Single-phase inverter closed loop

Single-phase inverter closed loop

-

Inverter voltage control accuracy

Inverter voltage control accuracy

-

Price of voltage inverter

Price of voltage inverter

-

DC panel inverter input voltage

DC panel inverter input voltage

-

Inverter adjusts voltage to 220

Inverter adjusts voltage to 220

-

High Voltage Inverter Kit

High Voltage Inverter Kit

-

Inverter module voltage

Inverter module voltage

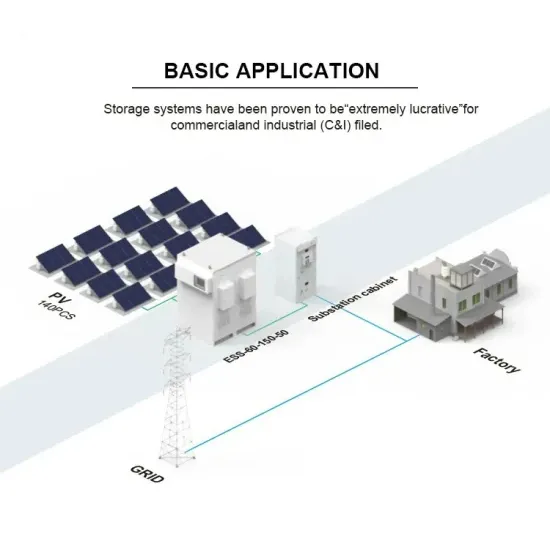

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

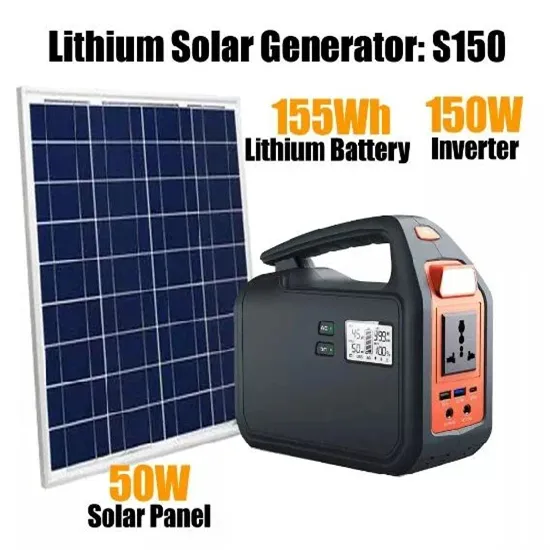

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.