Grid-Connected Inverter Anti-Islanding Test Results for

To have low-voltage ride-through capability, the DC bus voltage must be regulated so that the inverter can be operated as a constant current source. Because of issues found during this

Get a quote

Industrial Control Panel Design Standards and Best Practices

The DIN VDE 0126 – revision of the most important German safety Standard The standard defines the requirements for an automatic AC disconnect interface – it eliminates the need for

Get a quote

Enhancing safety: enclosures for low-voltage switchgear and

IEC 62208 specifies the constructional and performance requirements for enclosures that are intended to house electrical equipment such as circuit breakers, switches,

Get a quote

Inverter-Based Resource Performance Guideline

All GOPs with applicable resources are required to "operate each generator connected to the interconnected transmission system in the automatic voltage control mode (with its automatic

Get a quote

Low Voltage Switchgear and Controlgear Technical Document

The present technical manual is intended as an aid in project design and the application of low-voltage switchgear and controlgear in switchgear assemblies and machine control.

Get a quote

Metal Power Inverter Control Floor Outdoor Waterproof Low-Voltage

Metal Power Inverter Control Floor Outdoor Waterproof Low-Voltage Power Supply Cabinet, Find Details and Price about Cabinets Enclosures Electronic Metal Enclosure from Metal Power

Get a quote

Cabinet design and EMC

For detailed configuration instructions regarding the EMC-compliant design of drives and control cabinet configuration, refer to the "SINAMICS Low Voltage Configuration Manual".

Get a quote

Nordicab low voltage distribution cabinet

Nordicab low voltage distribution cabinets Nordicab low voltage distribution cabinets by ABB are easy to install and built to last. Based on our proven platform, they include improvements and

Get a quote

Control cabinet and control system construction

The frequency inverters are generally supplied for installation in the control cabinet, and manufacturers assume that, if necessary, the user will retrofit an

Get a quote

Electrical Installation Guide, IEC Standards

The Electrical Installation Guide is dedicated to professionals who design, install, inspect, and maintain low to medium-voltage electrical installations in

Get a quote

IEC and European Inverter Standards, Baltimore High

The DIN VDE 0126 – revision of the most important German safety Standard The standard defines the requirements for an automatic AC disconnect interface – it eliminates the need for

Get a quote

A review on single-phase boost inverter technology for low power

Solar Photovoltaic (SPV) inverters have made significant advancements across multiple domains, including the booming area of research in single-stage boosting inverter

Get a quote

Sinamics catalog

Into the digital future – with simplicity and versatility With the SINAMICS family of converters from Siemens, you can simply and efficiently address each individual drive application – in the low,

Get a quote

ITER Electrical Design Handbook Codes & Standards

In particular, voltage and current ratings must be selected for connection to the ITER standard nominal system voltages that have been selected from the IEC standards as given in the

Get a quote

Current limiting strategies for grid forming inverters under low

GFM inverters could replace SGs, providing synthetic inertia, stability in low strength grids and standalone operation by establishing the frequency and voltage [10].

Get a quote

Guide to PLC Cabinets: Types, Layout, Wiring

Learn the essentials of designing and wiring PLC control cabinets, including component selection, cooling, wiring tips, and safety standards.

Get a quote

Electrical Installation Guide, IEC Standards | Schneider Electric

The Electrical Installation Guide is dedicated to professionals who design, install, inspect, and maintain low to medium-voltage electrical installations in compliance with International

Get a quote

IEC 61439 Guide for Control Panel Builders

IEC 61439 is an international standard that sets the framework for the design, construction, and testing of low-voltage switchgear and control panels. It replaced the outdated IEC 60439

Get a quote

Power Distribution Cabinet Industrial Electric OEM

1.The power switch and protection frequency inverter cabinet l are equipped with low-voltage MCCB which is connected to the power line, in addition to

Get a quote

Guide to PLC Cabinets: Types, Layout, Wiring & Components

Learn the essentials of designing and wiring PLC control cabinets, including component selection, cooling, wiring tips, and safety standards.

Get a quote

AC-DC Inverter Cabinets

Elevate your power conversion solutions with Zekalabs AC-DC Inverter Cabinets, setting the standard for cutting-edge engineering. Meticulously designed to deliver unparalleled reliability,

Get a quote

Utility-scale battery energy storage system (BESS)

The main goal is to support BESS system designers by showing an example design of a low-voltage power distribution and conversion supply for a BESS system and its main components.

Get a quote

Frequency inverter for control cabinet application

Suitable for control and parameterisation, 4-digit, 7-segment display, direct control of a device, convenient control keypad, for installation in control cabinet doors.

Get a quote

Common Heat Dissipation Methods for Frequency Inverter Control Cabinets

Discover effective heat dissipation methods for frequency inverter control cabinets, including natural ventilation, forced ventilation, heat exchangers, and more.

Get a quote

Industrial Control Panel Design Standards and Best Practices

This article will go deeper into some control panel design concepts, focusing on standards and regulations and some of the industry''s best practices, including NFPA 70 and

Get a quote

6 FAQs about [Low voltage inverter control cabinet implementation standards]

What information does the present document provide about low-voltage switching and control devices?

The present document is designed to provide general technical information about the selection and application of low-voltage switching and control devices and does not claim to provide a comprehensive or conclusive presentation of the considered material.

Can electronic devices be used in low-voltage engineering?

The focus of the document is on electromechanical switchgear, however electronic devices used in low-voltage engineering have also been included. They are in many cases an effective alternative to mechanical devices. The discussions relate – insofar relevant – to the IEC standards, which correspond to the European CENELEC standards.

What parameters should be taken into consideration for a low-voltage device?

For the specific application of low-voltage devices additional parameters should be taken into account such as for example the application ambient temperature, the expected device life span, any influences from moisture, mechanical impacts and vibrations etc., to name only a few of the most important.

What are empty enclosures for low-voltage switchgear and controlgear assemblies?

Empty enclosures for low-voltage switchgear and controlgear assemblies refer to the physical structures or cabinets designed to house electrical equipment used in low-voltage power distribution systems.

How do you design a PLC control cabinet?

Wiring and Cabling: Organize your wiring carefully to prevent overheating and ensure safety. Keep power and signal cables separate, and use cable ties to keep things neat. Designing a PLC control cabinet requires careful planning to ensure that all components fit, function, and can be easily maintained. Here’s how to approach the design:

What are industrial control panels (ICPS)?

Industrial control panels (ICPs) contain electrical devices and control devices. Because of the different types of components, several standards and regulations apply to ICP design, production, and installation. ICPs must comply with these standards to ensure safety and performance.

Guess what you want to know

-

Moldova low voltage inverter price

Moldova low voltage inverter price

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Can I use an inverter if the battery voltage is low

Can I use an inverter if the battery voltage is low

-

Fire inverter control cabinet

Fire inverter control cabinet

-

Libya low voltage inverter manufacturer

Libya low voltage inverter manufacturer

-

Portugal low voltage inverter prices

Portugal low voltage inverter prices

-

Middle East low voltage inverter manufacturer

Middle East low voltage inverter manufacturer

-

Inverter fixed DC voltage control

Inverter fixed DC voltage control

-

Inverter voltage output is too low

Inverter voltage output is too low

-

Single-phase high and low voltage inverter

Single-phase high and low voltage inverter

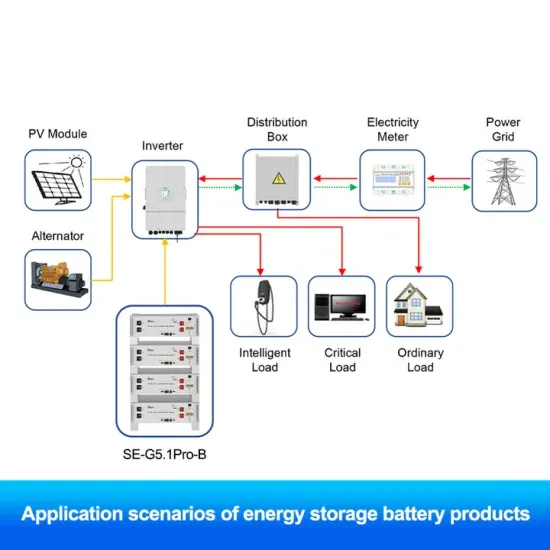

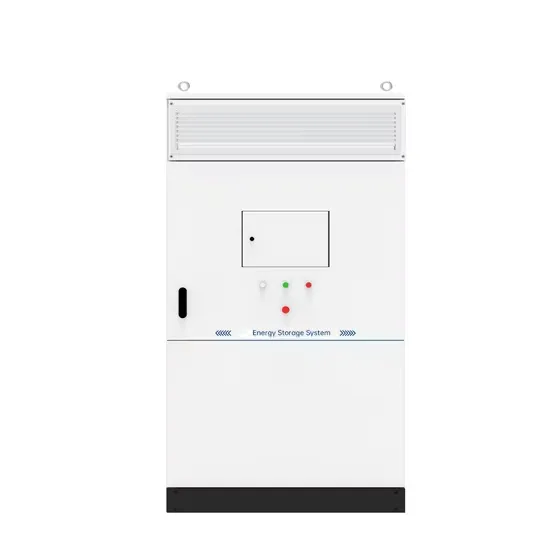

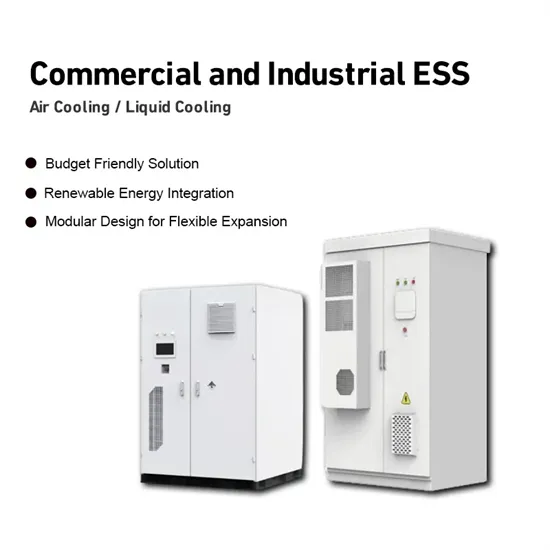

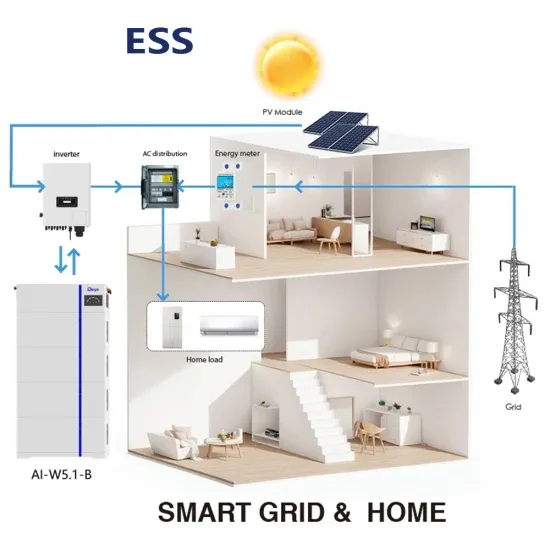

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.