Matching inverter to battery

When you convert the DC to AC, you will have conversion loss, so to get 2000W on the AC output of the inverter, then the input power to the inverter will be higher than the output

Get a quote

12 Volt DC Power Inverter: In-Depth Learning and

A 12-volt DC power inverter is an essential device for converting 12V direct current (DC) from a battery into 120V alternating current (AC),

Get a quote

Inverter Amp Draw Calculator

Inverters with a greater DC-to-AC conversion efficiency (90-95%) draw fewer amps, whereas inverters with a lower efficiency (70-80%) draw more current. Note: The results

Get a quote

Inverter Specifications and Data Sheet

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications

Get a quote

What Will An Inverter Run & For How Long? (With Calculator)

In general, a 3000 Watt inverter can draw as much as 350 Amps if it''s running on a 12V battery bank. If the 3000W inverter is running on a 24V

Get a quote

Inverter Current Calculator

Click "Calculate" to find out the current the inverter will draw from the battery or DC power source. This calculated current is essential for battery selection, cable sizing, and protecting your

Get a quote

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power

Get a quote

Inverter Current Calculator, Formula, Inverter Calculation

The current depends on the power output required by the load, the input voltage to the inverter, and the power factor of the load. The inverter draws current from a DC source to produce AC

Get a quote

What Will An Inverter Run & For How Long? (With Calculator)

So I''m gonna explain to you guys in simple words about what you can run on your any size inverter and what are the key point to keep in mind. And also how long your inverter

Get a quote

All About DC Inverter Air Condtioners (2025) | Today''s

When the control system determines it''s time to turn on the unit, the inverter converts the DC power back to AC and sends it to the compressor. If

Get a quote

How Many Amps Does an Inverter Draw?

Understanding the current draw of an inverter at different powers is an important part of designing and selecting a power system. This article provides current calculations for

Get a quote

How solar production affects power quality

Photovoltaic inverters may provide a current path through which DC residual current can pass to the AC side of the electrical installation, but

Get a quote

What Will An Inverter Run & For How Long? (With

Introduction - How does an inverter work? Our batteries store power in DC (Current current) but most of our household appliances require

Get a quote

Inverter Specifications and Data Sheet

Specifications provide the values of operating parameters for a given inverter. Common specifications are discussed below. Some or all of the specifications usually appear on the

Get a quote

How Much Power Does an Inverter Use on Standby?

Inverters are invaluable devices that convert direct current (DC) power from a battery or solar panels into alternating current (AC) power,

Get a quote

How many amps does a 3000 watt inverter draw?

In general, a 3000 Watt inverter can draw as much as 350 Amps if it''s running on a 12V battery bank. If the 3000W inverter is running on a 24V battery bank, it can draw up to

Get a quote

Inverter AC to DC Amperage Conversion Calculator | Battery Stuff

Our calculator will help you determine the DC amperage as it passes through a power inverter and provides the wattage rating you are pulling so you can properly size the

Get a quote

Efficiently Convert DC To AC

Understanding the Basics of Power Inverters Power inverters play a crucial role in converting direct current (DC) electricity into alternating current (AC) electricity. In this section, we will

Get a quote

Inverter Current Calculator & Formula Online Calculator Ultra

The inverter current calculation formula is a practical tool for understanding how much current an inverter will draw from its DC power source. The formula is given by:

Get a quote

How Many Amps Can I Get From A 2000W Inverter?

Therefore, a 2000W inverter operating at an output voltage of 120 volts may provide a maximum of 16.67 Amps of current. However, please note

Get a quote

What Is a Solar Inverter and How Does It Work?

Solar panels provide long-term savings and benefits, whereas the inverter is crucial for making the energy generated by solar panels usable by

Get a quote

How many amps will an inverter draw?

Also, how many amps does a 3000W inverter consume? In a vehicle''s DC charging system, the average size alternator is around 100 AMPS DC. This can be used to power an inverter

Get a quote

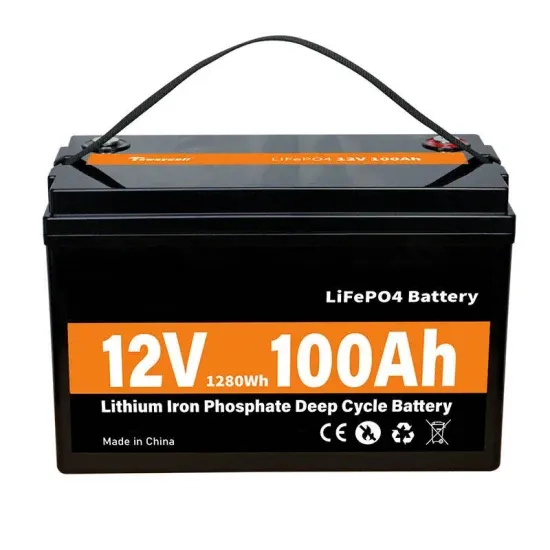

12 Volt Battery Run Time Calculator

Do you have a 12v device you need to power but don''t know what 12-volt battery you need? For those running a continuous 12-volt load, an adequately sized deep-cycle

Get a quote

All About DC Inverter Air Condtioners (2025) | Today''s Homeowner

When the control system determines it''s time to turn on the unit, the inverter converts the DC power back to AC and sends it to the compressor. If your space only needs to

Get a quote

6 FAQs about [How much current does the DC inverter provide ]

How do you calculate dc current from an inverter?

To calculate the DC current draw from an inverter, use the following formula: Inverter Current = Power ÷ Voltage Where: If you’re working with kilowatts (kW), convert it to watts before calculation: Inverter Current = 1000 ÷ 12 = 83.33 Amps So, the inverter draws 83.33 amps from a 12V battery. Inverter Current = 3000 ÷ 24 = 125 Amps

What is inverter current?

Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the load, the input voltage to the inverter, and the power factor of the load. The inverter draws current from a DC source to produce AC power.

How much current does a 3000 watt inverter draw?

If the 3000W inverter is running on a 24V battery bank, it can draw up to 175 Amps of current. If the battery bank is rated at 48V, the amp draw will not exceed 90 Amps. This is assuming the DC-to-AC conversion efficiency of the inverter (@ 3000 Watts) is around 85%.

How much current does an inverter draw?

The current drawn is approximately 104.17 amps. Understanding how much current your inverter draws is vital for several reasons: Battery Bank Sizing: Knowing the current helps determine how many batteries you need and how long they will last. Cable Sizing: Undersized cables can overheat or fail.

How does AC inverter power affect DC input voltage?

The AC inverter power, P i required by the load determines how much current the inverter needs to draw from the DC source. This is influenced by the efficiency of the conversion process, represented by the power factor, PF. The DC input voltage, V i provided to the inverter affects the amount of current drawn.

How many amps do inverters draw?

Inverters with a greater DC-to-AC conversion efficiency (90-95%) draw fewer amps, whereas inverters with a lower efficiency (70-80%) draw more current. Note: The results may vary due to various factors such as inverter models, efficiency, and power losses. Here is the table showing how many amps these inverters draw for 100% and 85 % efficiency.

Guess what you want to know

-

How many watts of solar DC power supply does it provide

How many watts of solar DC power supply does it provide

-

How much power can a 3kw inverter provide

How much power can a 3kw inverter provide

-

Current inverter intermediate DC link

Current inverter intermediate DC link

-

How much current does a 2200 watt inverter draw when connected to 12v

How much current does a 2200 watt inverter draw when connected to 12v

-

High-voltage DC to AC inverter

High-voltage DC to AC inverter

-

How much current does a nine-volt photovoltaic panel have

How much current does a nine-volt photovoltaic panel have

-

Luxembourg DC panel inverter

Luxembourg DC panel inverter

-

Bangladesh DC power inverter brand

Bangladesh DC power inverter brand

-

How much does the inverter equipment for German communication base stations cost

How much does the inverter equipment for German communication base stations cost

-

How many components does a 5kw inverter require

How many components does a 5kw inverter require

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.