Multiloop Control Design for Buck Converter

This example is based on the article Cascade Digital PID Control Design for Power Electronic Converters. The article describes the workflow to tune the

Get a quote

Research on Dual-Closed-Loop Control Strategy for LCL-Type

A dual closed-loop feedforward control strategy is proposed for the current inner loop and voltage outer loop in the rotating coordinate system. The correctness of the inverter

Get a quote

How does a voltage controller (outer loop) set the current

I am currently trying to understand the cascaded current-voltage control of a boost converter (and later design the PI-controller). Let me summarize the information I have

Get a quote

Optimal Structures for Voltage Controllers in Inverters

In this paper, we pose an optimal voltage control problem for ac inverter systems and study the structure of the resulting feedback laws.

Get a quote

A Novel Double Closed-loop Control Method for Single-phase

The goal of DC voltage dynamic response speed improvement and unit power factor realization is the rectifier oriented. Based on current inner loop DQ decoupling control and

Get a quote

Applications of Outer Loop and Inner Loop Controllers in Inverter

Outer loop controllers handle slow dynamics like power, voltage, and frequency regulation. Inner loop controllers ensure fast current/voltage tracking and disturbance

Get a quote

Optimal Design of Nested Current and Voltage Loops in Grid

This paper presents a method to optimally design the nested control loops of a grid-connected converter. Conventionally, the inner loop is designed to be at lea.

Get a quote

Inner-Loop Controllers for Grid-Forming Converters

This paper presents a detailed discrete-time implementation of an inner-loop voltage controller with a current limiter for grid-forming converters

Get a quote

A Voltage-Source Inverter for Microgrid Applications with an

The control technique is designed in the time domain, combining an in- ner current control loop with an outer voltage control loop. Voltage regulation under various linear and non-linear load

Get a quote

Modelling, control design, and analysis of the inner control''s loops

In this paper, an in-depth investigation of the modelling, control design, and analysis of the voltage and current inner control loops intended for single-phase voltage-controlled VSIs

Get a quote

Outer voltage control loop and inner current control

Outer voltage control loop and inner current control loop for the left hand side boost converter leg. A boost DC/AC converter is popular in AC line-integrated

Get a quote

Modeling and Design of Primary Control''s Inner Loops for Droop

in Microgrid (MG) systems, the output voltage controller within the primary control, called the "inner control is essential for regulating the output of the inverters and guaranteeing a high

Get a quote

A Current Control Method for Grid-Connected

Filter-based active damping improves stability by adding a digital filter next to the current controller [10]. In feedback-based active damping, the

Get a quote

Dual-loop Control Strategy for Grid-connected Inverter

Theoretically, the outer loop (the DC voltage controller) should have a smaller bandwidth than the inner loop (the current controller). In practice,

Get a quote

Dual loop control for single phase PWM inverter for distributed

In this paper the design of synchronous frame DQ control based double loop control for single phase inverter in distributed generation system is proposed. For synchronous frame

Get a quote

Research on Dual-Closed-Loop Control Strategy for LCL

This paper has analyzed in detail the implementation principles and process of the three-phase LCL grid-tied inverter, and has adopted the dual closed-loop feedforward control method of

Get a quote

A voltage-source inverter for microgrid applications with an inner

To constrain the inverter current within its safety limits, a fast current controller is used in the inner loop, having a reference current obtained by the outer-loop voltage regulation.

Get a quote

Research on Double Closed Loop Control Method of Single

This paper presents a double-closed-loop PWM design and control method for single-phase inverter current inner loop and voltage outer loop.

Get a quote

Adaptive robust dual-loop control for voltage and current in

To overcome this shortcoming and achieve power sharing among all parallel inverters, it is necessary to control both the outer voltage loop and inner current loop, which is referred to as

Get a quote

Research on Double Closed Loop Control Method of Single-Phase Inverter

This paper presents a double-closed-loop PWM design and control method for single-phase inverter current inner loop and voltage outer loop.

Get a quote

Inverter Design with Average Current and Voltage Loop Control

In this video, PSIM & SmartCtrl are used to implement an inner average current mode control loop and an outer voltage loop. PSIM is used to size the energy storage

Get a quote

Boost PFC Converter

The inner loop is a current loop, and the outer loop is a voltage loop. Note that the PFC boost converter design must be carried out sequentially, first with the current loop, and

Get a quote

Optimal Design of Nested Current and Voltage Loops in Grid-Connected

This paper presents a method to optimally design the nested control loops of a grid-connected converter. Conventionally, the inner loop is designed to be at least several times faster than

Get a quote

Outer voltage control loop and inner current control loop for the

Outer voltage control loop and inner current control loop for the left hand side boost converter leg. A boost DC/AC converter is popular in AC line-integrated energy storage systems...

Get a quote

Detailed analysis of inverter linear control loops design

This paper thoroughly analyzes various linear control loop designs of DC-AC inverters. First, the PI and P+Resonant controllers for current mode

Get a quote

Optimal Design of Nested Current and Voltage Loops in Grid-Connected

This paper presents a method to optimally design the nested control loops of a grid-connected converter. Conventionally, the inner loop is designed to be at lea.

Get a quote

Guess what you want to know

-

60kw inverter grid-connected current and voltage

60kw inverter grid-connected current and voltage

-

Single voltage closed loop inverter

Single voltage closed loop inverter

-

Pure dual voltage inverter

Pure dual voltage inverter

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Inverter adjusts voltage to 220

Inverter adjusts voltage to 220

-

Macedonia voltage stabilizer inverter price

Macedonia voltage stabilizer inverter price

-

The inverter voltage rises slowly

The inverter voltage rises slowly

-

Photovoltaic panels with low voltage and high current

Photovoltaic panels with low voltage and high current

-

Ultra-high voltage DC inverter

Ultra-high voltage DC inverter

-

Photovoltaic low voltage inverter

Photovoltaic low voltage inverter

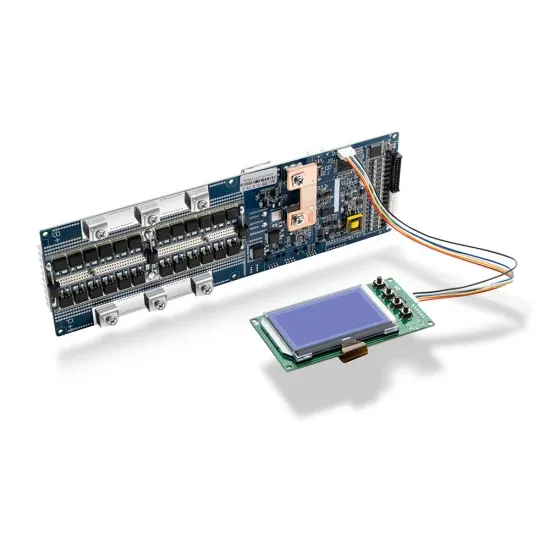

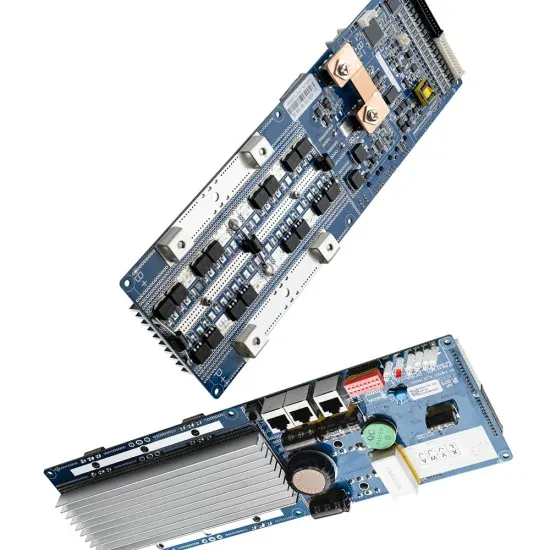

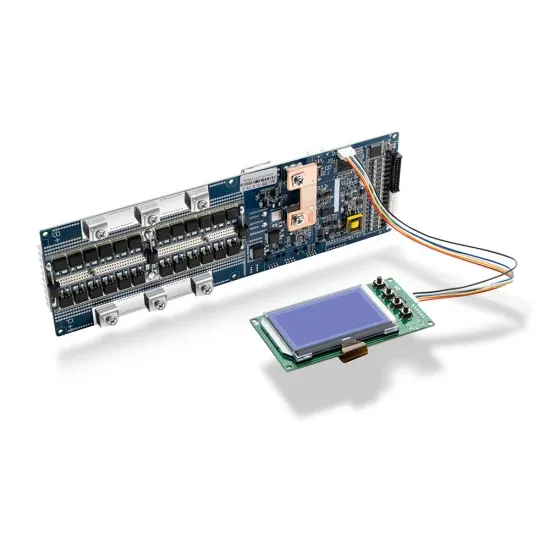

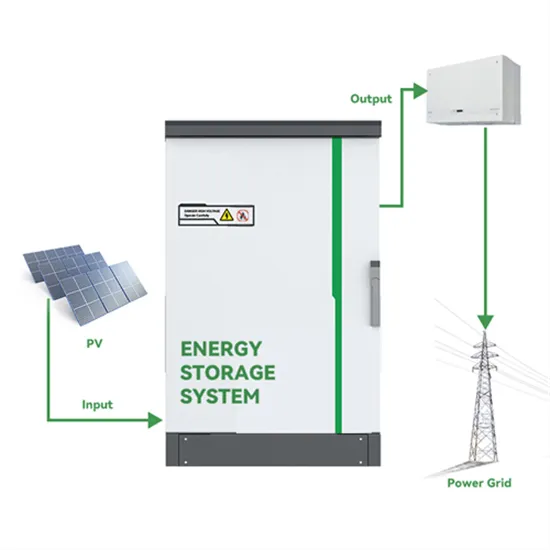

Industrial & Commercial Energy Storage Market Growth

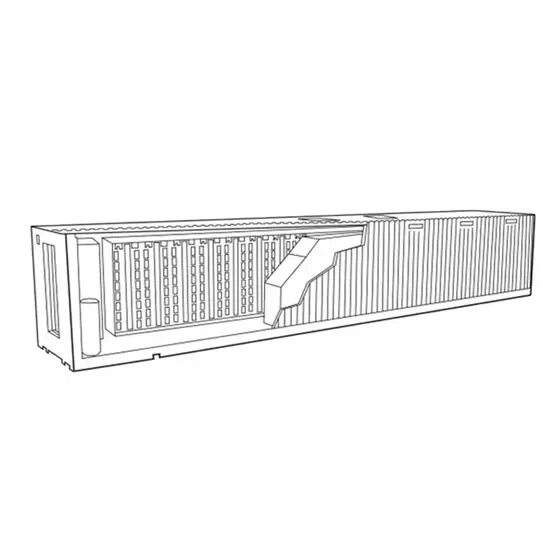

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.