Voltage Source Inverter Design Guide (Rev. B)

Voltage source inverters (VSI) are commonly used in uninterruptible power supplies (UPS) to generate a regulated AC voltage at the output. Control design of such inverter is challenging

Get a quote

Microinverter Voltage Rise Design Issue (Enphase users beware!)

Voltage Rise Wires have resistance causing Voltage Drop. All grid-tied inverters increase voltage to export power. Typically they only need to raise the voltage above the grid

Get a quote

Microinverter Voltage Rise Design Issue (Enphase

Voltage Rise Wires have resistance causing Voltage Drop. All grid-tied inverters increase voltage to export power. Typically they only need to

Get a quote

How to calculate voltage rise in a solar pv system?

Voltage rise is the difference between the voltage in the grid, the power system that provides the electricity, and your solar inverter, which produces energy..

Get a quote

Power Inverter Troubleshooting – Common Problems

By understanding the common issues that can affect power inverters and how to troubleshoot them, you can keep your backup power

Get a quote

When I connect any load trough the bms voltage drops to 3 v and

Everything is hooked correctly, when I switch on any inverter drops the voltage to 0 again and rises slowly when I turn it off. When I measure B- with P- with voltage, it drops slowly when

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage. This is caused by a high intermediate circuit DC voltage. This

Get a quote

Overvoltage is impacting your Solar Systems

Recently UNSW released a study exposing the grid voltage rate in Australia which is affecting homes with solar systems and the results they found weren''t

Get a quote

Struggling to Eliminate voltage spike tripping my

The power supply would sense this rise in output voltage in its feedback network and sum it into its compensation and decide how much to alter the output. You

Get a quote

10 common inverter failure and the solutions –

Common causes and solutions for low DC input voltage: The open circuit voltage of the string should be much greater than the minimum input

Get a quote

When I connect any load trough the bms voltage drops to 3 v and rises

Everything is hooked correctly, when I switch on any inverter drops the voltage to 0 again and rises slowly when I turn it off. When I measure B- with P- with voltage, it drops

Get a quote

PWM Voltage Rise Time and Pulse Width Control to Minimize

Pulse width modulated (PWM) shaped voltages provides a flexible approach to control electrical motors efficiently. The downside is that the voltage stress imposed on

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always working efficiently!

Get a quote

Preventing Start-Up Issues Due to Output Inrush in

Inductor Current Peak Figure 8 shows inductor voltage and current waveforms of a buck-boost inverter in a steady-state condition in continuous conduction

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

This guide takes an in-depth look at the most common power inverter problems faced by users and provides actionable solutions backed by

Get a quote

On sunny days, Inverter switches off when DC voltage gets too

he inverter DC voltage, spikes from 2x 330v (=720v) to 2 x 387v (=774v). At other times of the day, when the battery reaches 100%, the DC voltage is not as high and the

Get a quote

Voltage Troubles? A Guide to Diagnosing Inverter Low Voltage

Many people face issues with inverter low voltage at some point in their lives. In this blog post, we will guide you on how to diagnose and potentially fix these problems.

Get a quote

10 common inverter failure and the solutions – TYCORUN

Common causes and solutions for low DC input voltage: The open circuit voltage of the string should be much greater than the minimum input voltage of the inverter; if there are

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always

Get a quote

High Voltage Spike (dV/dt) and Motor Protection

There are two different phenomena that can create high dV/dt and high peak voltages. Reflective Wave Phenomenon Voltage wave reflection is

Get a quote

Voltage Source Inverter Reference Design (Rev. E)

Description This reference design implements single-phase inverter (DC/AC) control using a C2000TM microcontroller (MCU). The design supports two modes of operation for the inverter:

Get a quote

Power Inverter Problems: 5 Most Frequent Issues and How to Solve

This guide takes an in-depth look at the most common power inverter problems faced by users and provides actionable solutions backed by specialized knowledge. By the

Get a quote

Concerns Over Inverter Output Voltage Instability on the Rise

Key among them is the fluctuation in input voltage from the grid or solar panels, which can lead to inconsistent output if the inverter''s voltage regulation system is unable to compensate effectively.

Get a quote

Implications of Slow or Floating CMOS Inputs (Rev. E)

Because the device''s internal power-supply nodes are used as voltage references throughout the integrated circuit, inductive voltage spikes, VGND, affect the way signals appear to the internal

Get a quote

What causes these peaks in the output voltage of a CMOS inverter?

If the rise / fall times of the inverter''s input signal are high enough, the Drain-Gate capacitance is sufficient to cause peaks / spikes at the output during the voltage transitions.

Get a quote

PV output drops during peak sun hours

Generation rises, voltage rises, the inverter cuts out, the voltage drops, repeat. This is reinforced by the seeming correlation between high loads and solar working.

Get a quote

Power Inverter Troubleshooting – Common Problems and How to

By understanding the common issues that can affect power inverters and how to troubleshoot them, you can keep your backup power system running smoothly. Regular

Get a quote

6 FAQs about [The inverter voltage rises slowly]

What causes a DC inverter to overvoltage?

This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage. There are other causes of DC overvoltage, however. POSSIBLE FIXES: Turn the overvoltage controller is on. Check supply voltage for constant or transient high voltage. Increase deceleration time.

Why is my inverter low voltage?

Another possible cause could be an inadequate power source or improper electrical connections. Faulty wiring can also result in voltage fluctuations. If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health.

Why is my inverter screen not working?

Reason 3: The DC input voltage is too low. When the string output voltage is lower than the minimum input voltage of the inverter, there is no display on the inverter screen. To make sure, you can use a multimeter to measure the output voltage of the photovoltaic string to see whether the voltage reaches the minimum input voltage of the inverter.

What are the most common power inverter problems?

Over 60% of inverter failures stem from preventable problems such as loose connections, overloaded circuits, or poor maintenance. This guide takes an in-depth look at the most common power inverter problems faced by users and provides actionable solutions backed by specialized knowledge.

What happens if a solar inverter is too low?

The open circuit voltage of the string should be much greater than the minimum input voltage of the inverter; if there are too few modules in series, the open circuit voltage of the string will be too low, resulting in no display on the inverter screen. Solution: Increase the number of solar panels in series.

Why is my inverter not turning?

The inverter’s output current is 1.2 times greater than the rated motor current and continues for over 2 minutes. Please check if the parameter setting for the motor’s rated current is correct. Also, check if the motor or load machinery is blocked and if the power supply voltage is too low. 17. The motor does not turn after the inverter is running.

Guess what you want to know

-

Inverter low-voltage side voltage

Inverter low-voltage side voltage

-

Belize high voltage inverter manufacturer

Belize high voltage inverter manufacturer

-

72v inverter minimum voltage

72v inverter minimum voltage

-

What is the normal inverter voltage in Bosnia and Herzegovina

What is the normal inverter voltage in Bosnia and Herzegovina

-

Greece Voltage Inverter

Greece Voltage Inverter

-

220 voltage inverter

220 voltage inverter

-

Where can I buy a voltage inverter

Where can I buy a voltage inverter

-

Three-phase energy storage low voltage inverter

Three-phase energy storage low voltage inverter

-

What voltage is suitable for a 2200w inverter

What voltage is suitable for a 2200w inverter

-

What is the voltage of the photovoltaic inverter

What is the voltage of the photovoltaic inverter

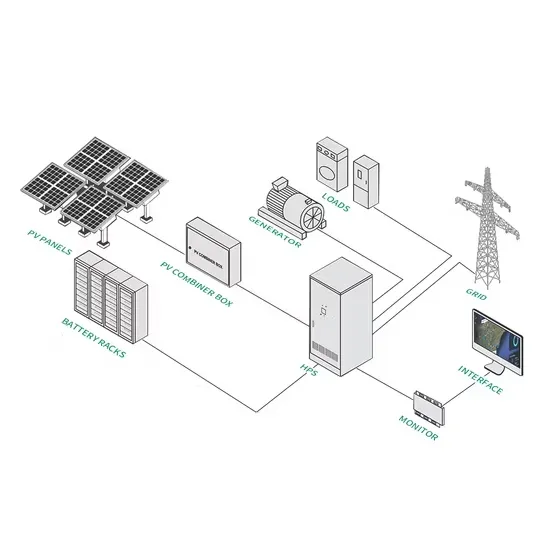

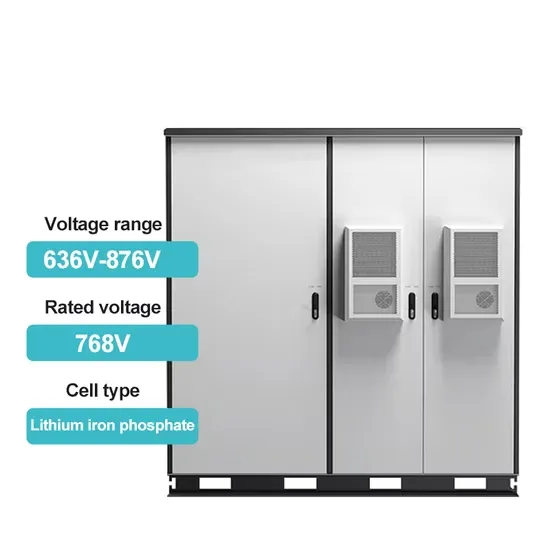

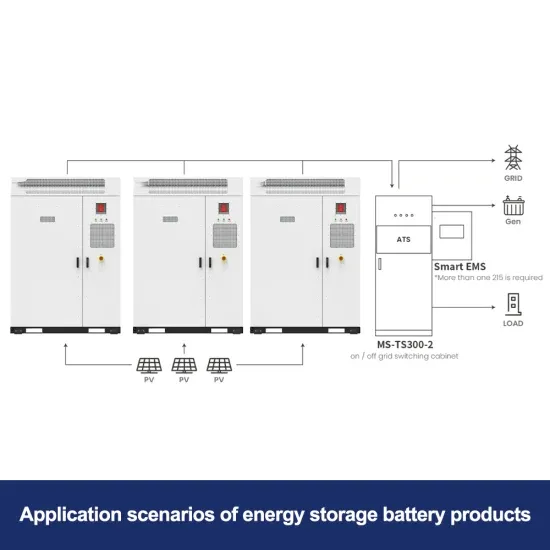

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

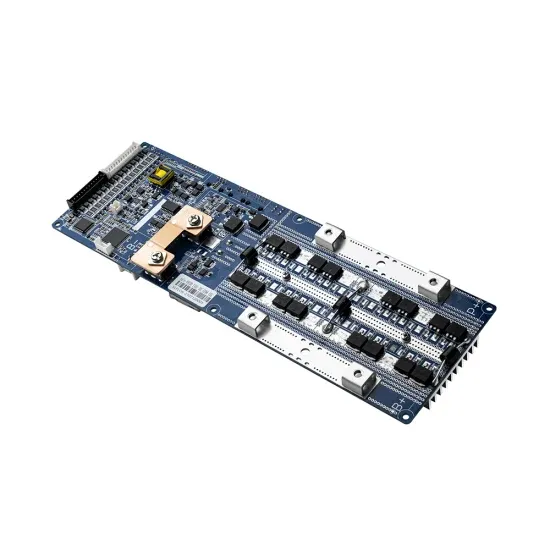

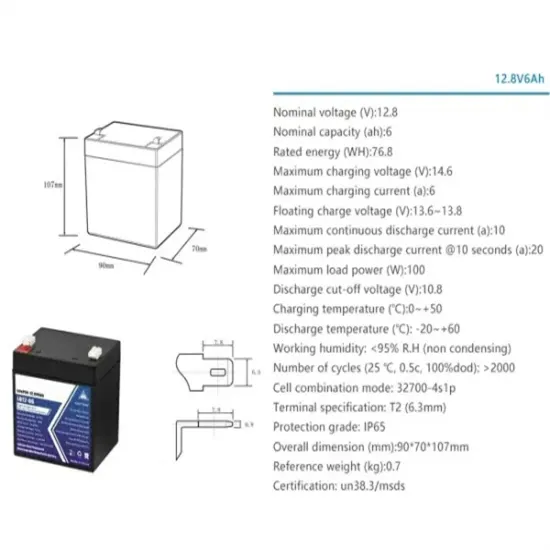

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.