Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components, characteristics, applications,

Get a quote

Technology: Flywheel Energy Storage

Large synchronous flywheels are also used for energy storage, yet not to be mistaken with FESS. They use very large flywheels with a mass in the order of 100 tonnes. These are directly

Get a quote

Flywheel Energy Storage Calculator | Mechanical Engineering

To determine the appropriate size of a flywheel energy storage system, a flywheel energy storage calculator can be used. This calculator takes into account several factors, including the

Get a quote

Energy Storage Flywheel Rotors—Mechanical Design

Energy storage flywheel systems are mechanical devices that typically utilize an electrical machine (motor/generator unit) to convert electrical energy in mechanical energy and vice

Get a quote

A comprehensive review of Flywheel Energy Storage System

Energy storage systems (ESSs) play a very important role in recent years. Flywheel is one of the oldest storage energy devices and it has several benefits. Flywheel Energy

Get a quote

Flywheel Energy Storage System Dimensions: Balancing Power

NASA''s 2023 lunar base prototype uses a flywheel smaller than a beer keg yet stores enough energy to power six ISS modules. Here''s what modern engineers consider: 1.

Get a quote

Flywheel energy and power storage systems

Small-scale flywheel energy storage systems have relatively low specific energy figures once volume and weight of containment is comprised. But the high specific power

Get a quote

SUPERFLYWHEEL ENERGY STORAGE SYSTEM David

Until recently, the use of flywheel storage systems has been limited to a very few applications. The principal disadvantages of these devices have been the limited energy storage capability

Get a quote

Design and Research of a New Type of Flywheel Energy Storage

This article proposes a novel flywheel energy storage system incorporating permanent magnets, an electric motor, and a zero-flux coil. The permanent magnet is utilized

Get a quote

DOE ESHB Chapter 7 Flywheels

Over the past 50 years of the development of flywheel energy storage systems, numerous unusual configurations have been explored. These include straight fibers oriented along the

Get a quote

Industrial Solutions Flywheel UPS Systems, 50-1000 kVA

How the Flywheel Works The flywheel energy storage system works like a dynamic battery that stores energy by spinning a mass around an axis. Electrical input spins the flywheel hub up to

Get a quote

Design Optimization of a Rotor for Flywheel Energy

The aim of this study is to design and shape optimization of flywheel rotor with different combinations of diameter and height with constant

Get a quote

Flywheel energy storage

One of the primary limits to flywheel design is the tensile strength of the material used for the rotor. Generally speaking, the stronger the disc, the faster it may be spun, and the more

Get a quote

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Get a quote

Flywheel Diameter: Calculating Capacity for Energy Storage

Hey all, I realize that when weight is moved from the center of a flywheel toward the outer edge (or a larger diameter wheel is used), the capacity for energy storage increases. But

Get a quote

Flywheel Energy Storage Calculator

Our flywheel energy storage calculator allows you to compute all the possible parameters of a flywheel energy storage system. Select the desired units, and fill in the fields related to the

Get a quote

Overview of Control System Topology of Flywheel

The electrical power is applied to the motor causing the flywheel spinning high speed, and this spinning mass has kinetic energy is converted

Get a quote

Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components,

Get a quote

Flywheel | Energy Storage, Kinetic Energy

The energy stored in a flywheel, however, depends on both the weight distribution and the rotary speed; if the speed is doubled, the kinetic

Get a quote

Flywheel Energy Storage Calculator

Our flywheel energy storage calculator allows you to compute all the possible parameters of a flywheel energy storage system. Select the desired units, and

Get a quote

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get a quote

A review of flywheel energy storage systems: state of the art

Primary candidates for large-deployment capable, scalable solutions can be narrowed down to three: Li-ion batteries, supercapacitors, and flywheels. The lithium-ion

Get a quote

Overview of Flywheel Systems for Renewable Energy

storage systems (FESS) are summarized, showing the potential of axial-flux permanent-magnet (AFPM) machines in such applications. Design examples of high-speed AFPM machines a e

Get a quote

The most complete analysis of flywheel energy

This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other

Get a quote

Guess what you want to know

-

Flywheel energy storage is considered perpetual motion

Flywheel energy storage is considered perpetual motion

-

How to replace flywheel energy storage wind power

How to replace flywheel energy storage wind power

-

When the flywheel energy storage is discharged the flywheel acts as

When the flywheel energy storage is discharged the flywheel acts as

-

What are the flywheel energy storage brands

What are the flywheel energy storage brands

-

Flywheel energy storage frequency

Flywheel energy storage frequency

-

Nauru Flywheel Energy Storage

Nauru Flywheel Energy Storage

-

Flywheel energy storage high voltage distribution cabinet

Flywheel energy storage high voltage distribution cabinet

-

Huawei develops flywheel energy storage

Huawei develops flywheel energy storage

-

Flywheel energy storage equipment for sale

Flywheel energy storage equipment for sale

-

Swedish flywheel energy storage equipment manufacturer

Swedish flywheel energy storage equipment manufacturer

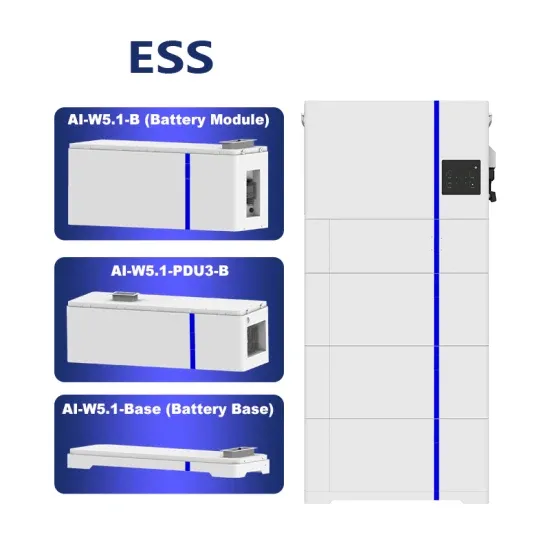

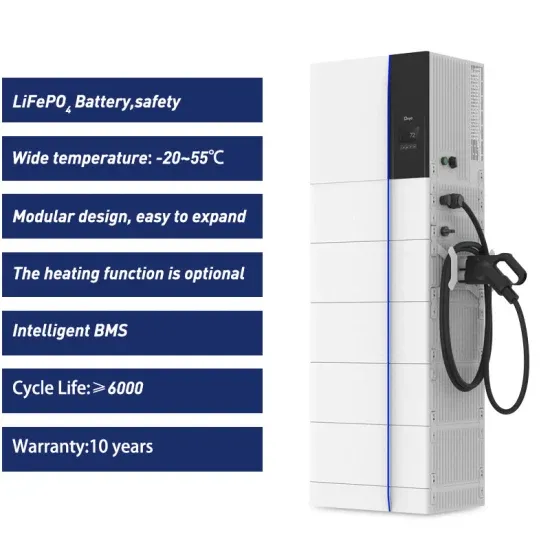

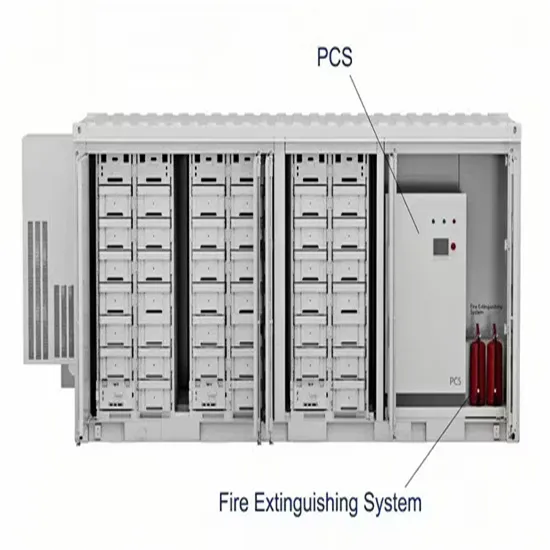

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.