Is Free Energy Possible? The Science of Perpetual Motion

Both types of perpetual motion machines are impossible because their operation fundamentally contradicts these well-established and experimentally verified laws of physics. Distinguishing

Get a quote

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Get a quote

What is the principle of flywheel energy storage

Flywheel energy storage is a sophisticated technology harnessing kinetic energy to provide a multitude of applications, particularly in energy

Get a quote

Flywheel Energy Storage System: What Is It and How Does It

A flywheel energy storage system is a mechanical device used to store energy through rotational motion. When excess electricity is available, it is used to accelerate a flywheel to a very high

Get a quote

A review of flywheel energy storage systems: state of the art

ESSs store intermittent renewable energy to create reli-able micro-grids that run continuously and e ciently distribute electricity by balancing the supply and the load [1]. The existing energy

Get a quote

Hall''s Conjoined Flywheels Perpetual Motion Machine

Here, the first flywheel is accelerated--via the belt, the first flywheel then accelerates the second flywheel. The second flywheel, having been energized

Get a quote

Utah man creates company devoted to flywheel

This is incorrect, using flywheels for energy storage has been a viable solution for many decades and many units are in commercial service and have been for

Get a quote

Questions on Perpetual motion machines? : r/badscience

Just some questions about perpetual motion machines? If I had a ring around earth exactly where the centrifugal forces of gravity pull and push (like where the ISS is located) and then put a

Get a quote

Flywheel Energy Storage Systems (FESS)

Flywheel energy storage systems (FESS) use electric energy input which is stored in the form of kinetic energy. Kinetic energy can be described as "energy of motion," in this case the motion

Get a quote

Flywheel: Definition, Function, Construction, Working

A flywheel is a heavy circular disc-like structure that is connected to the output shaft of the engine. It sounds very common when we talk about

Get a quote

A review of flywheel energy storage systems: state of the art

Energy storage systems (ESS) play an essential role in providing continu-ous and high-quality power. ESSs store intermittent renewable energy to create reliable micro-grids

Get a quote

Flywheel Energy Storage Systems (FESS)

Flywheel energy storage systems (FESS) use electric energy input which is stored in the form of kinetic energy. Kinetic energy can be described as

Get a quote

What is the principle of flywheel energy storage | NenPower

Flywheel energy storage is a sophisticated technology harnessing kinetic energy to provide a multitude of applications, particularly in energy management systems. By employing

Get a quote

Flywheel Energy Storage | Page 2 | DIY Solar Power

Yes, the flywheel tends to attract the perpetual motion crowd . My idea of putting moving parts on a flywheel is a recipe for disaster! Though 100

Get a quote

Power Multiplication using Flywheel to Produce Electricity

When energy is extracted from the system, the flywheel''s rotational speed is reduced as a consequence of the principle of conservation of energy, adding energy to the system

Get a quote

Flywheel energy storage Australia: Amber Kinetics

Flywheels get storage moving in the right direction Harnessing kinetic energy and perpetual motion, flywheels are a game-changing way of storing energy for

Get a quote

Flywheel Energy Storage System: What Is It and How

A flywheel energy storage system is a mechanical device used to store energy through rotational motion. When excess electricity is available, it is used to

Get a quote

A review of flywheel energy storage systems: state of the art and

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Get a quote

(PDF) A review on how a Perpetual Motion Machine

Thus, the types of perpetual motion machines can be classified into three types i. A perpetual motion system of the primary kind creates work without the contribution of energy.

Get a quote

The Flywheel Energy Storage System: A Conceptual Study,

Flywheel Energy Storage (FES) system is an electromechanical storage system in which energy is stored in the kinetic energy of a rotating mass. Flywheel systems are composed of various

Get a quote

r builds 3D printed model of a fake "perpetual

r Robert Murray-Smith has built a mechanical model of a coupled flywheel-spring mechanism called Dominant Flywheel. The design is

Get a quote

The Physics of a Puzzling Perpetual Motion Machine

Perpetual motion—it''s fun to say that. For some people, perpetual motion machines hold the secret to everlasting free energy that will save the

Get a quote

The Whole Process of Flywheel Energy Storage: From Basics to

Imagine a giant, supercharged spinning top that stores electricity like a battery—that''s flywheel energy storage in a nutshell. This 21st-century "mechanical battery"

Get a quote

Patent for ''Kamma gear flywheel power generation''

For the first time in the country, probably in the world, a patent has been issued to flywheel-based power generation, the first-of-its-kind fuel-less power generation technology.

Get a quote

6 FAQs about [Flywheel energy storage is considered perpetual motion]

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

How efficient is a flywheel energy storage system?

Their efficiency is high during energy storage and energy transfer (>90 %). The performance of flywheel energy storage systems operating in magnetic bearing and vacuum is high. Flywheel energy storage systems have a long working life if periodically maintained (>25 years).

What is a flywheel energy storage system (fess)?

And the power will be obtained in dc. This generator consists of Flywheel energy storage system (FESS) with slight modification like, instead of using it for the power back up system as utilized in satellites by NASA, we use to generate continues flow of electricity unto the inertia of the flywheel.

Can small applications be used instead of large flywheel energy storage systems?

Small applications connected in parallel can be used instead of large flywheel energy storage systems. There are losses due to air friction and bearing in flywheel energy storage systems. These cause energy losses with self-discharge in the flywheel energy storage system.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What are the disadvantages of Flywheel energy storage systems?

In addition, this storage technology is not affected by weather and climatic conditions . One of the most important issues of flywheel energy storage systems is safety. As a result of mechanical failure, the rotating object fails during high rotational speed poses a serious danger. One of the disadvantages of these storage systems is noise.

Guess what you want to know

-

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

-

Huawei s Largest Flywheel Energy Storage Project

Huawei s Largest Flywheel Energy Storage Project

-

Huawei Colombia Energy Storage Flywheel

Huawei Colombia Energy Storage Flywheel

-

Flywheel energy storage energy cost

Flywheel energy storage energy cost

-

Flywheel energy storage discharge efficiency

Flywheel energy storage discharge efficiency

-

Superconducting flywheel energy storage cost

Superconducting flywheel energy storage cost

-

Samoan Flywheel Energy Storage Enterprise

Samoan Flywheel Energy Storage Enterprise

-

Flywheel energy storage 5MWH liquid cooling installation

Flywheel energy storage 5MWH liquid cooling installation

-

Flywheel energy storage equipment unit price

Flywheel energy storage equipment unit price

-

Processing flywheel energy storage

Processing flywheel energy storage

Industrial & Commercial Energy Storage Market Growth

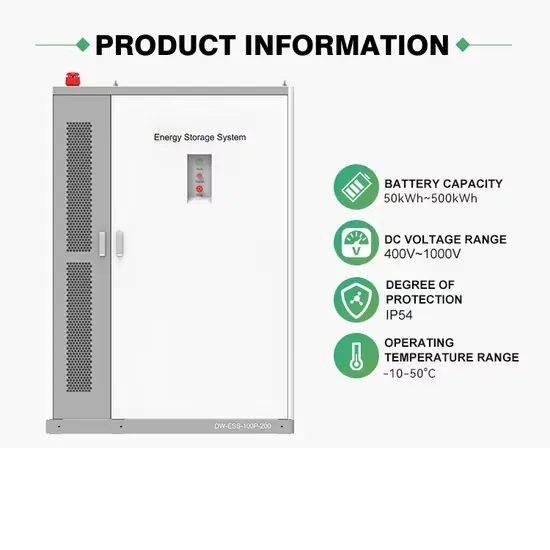

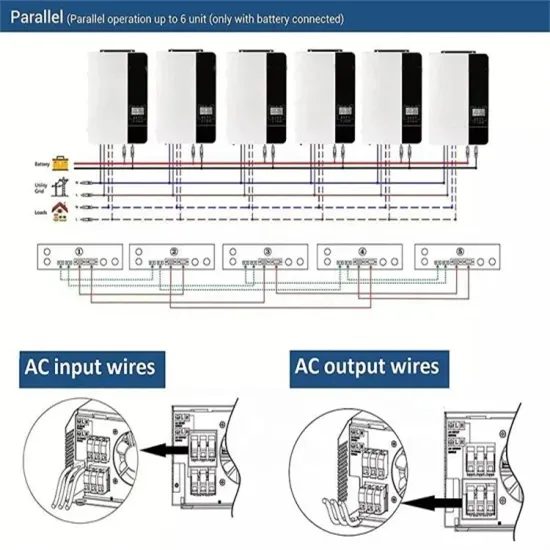

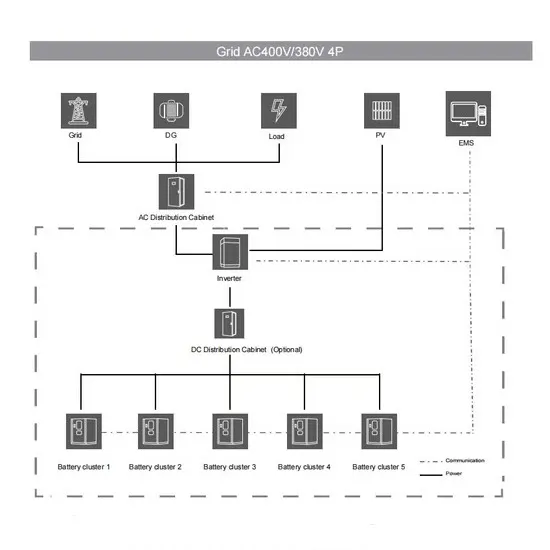

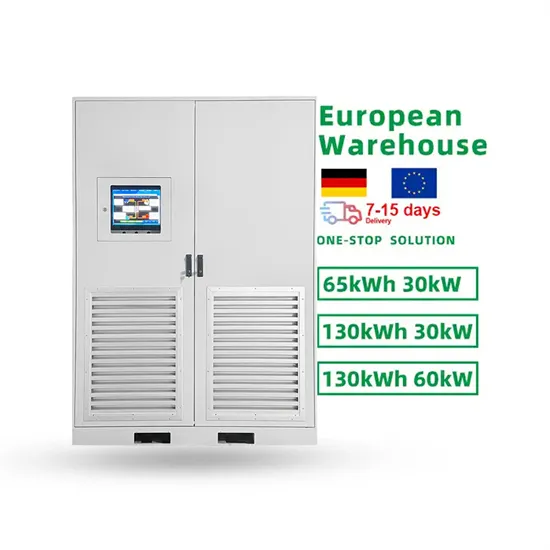

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.