What Determines Flywheel Energy Storage Discharge Time? The

The secret often lies in flywheel energy storage discharge time – the unsung hero of instant power delivery. Unlike batteries that need coffee breaks to recharge, flywheels spin

Get a quote

Principle of flywheel energy storage generator

How Flywheel Energy Storage Systems Work. Flywheel energy storage systems (FESS) employ kinetic energy stored in a rotating mass with very low frictional losses. Electric energy input

Get a quote

A review of flywheel energy storage systems: state of the art and

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Get a quote

Flywheel energy storage

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy. When energy is extracted from the

Get a quote

How flywheel energy storage works

principle of rotating mass causes energy to store in a flywheel by converting electrical energy into mechanical energy in the form of rotational kinetic energy. 39 The energy fed to an FESS is

Get a quote

Chapter 4 Flywheel Energy Storage System

Flywheel energy storage stores energy in the form of mechanical energy in a high-speed rotating rotor. The core technology is the rotor material, support bearing, and electromechanical control

Get a quote

Flywheel Energy Storage

Flywheel energy storage is defined as a method for storing electricity in the form of kinetic energy by spinning a flywheel at high speeds, which is facilitated by magnetic levitation in an

Get a quote

A review of flywheel energy storage systems: state of the art

The drawback of supercapacitors is that it has a narrower discharge duration and signi cant self-discharges. Energy storage ywheels are usually supported by active magnetic bearing (AMB)

Get a quote

Applications of flywheel energy storage system on load frequency

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

Get a quote

Grid-Scale Flywheel Energy Storage Plant

Flywheel systems are kinetic energy storage devices that react instantly when needed. By accelerating a cylindrical rotor (flywheel) to a very high speed and maintaining the energy in

Get a quote

DOE ESHB Chapter 7 Flywheels

In their modern form, flywheel energy storage systems are standalone machines that absorb or provide electricity to an application. Flywheels are best suited for applications that require high

Get a quote

Modeling Methodology of Flywheel Energy Storage System

A flywheel acts like a mechanical battery that stores energy in kinetic form. The flywheel works based on Newton''s first law of motion applied to rotating systems, wherein the flywheel keeps

Get a quote

Technology: Flywheel Energy Storage

For discharging, the motor acts as a generator, braking the rotor to produce electricity. Each FESS module has a power electronics module which allows its AC motor-generator to

Get a quote

What is the self-discharge rate of flywheel energy

The self-discharge rate of flywheel energy storage refers to the proportion of stored energy that a flywheel loses to its surroundings over time

Get a quote

What is a flywheel energy storage system? | NenPower

A flywheel energy storage system is a mechanical device that utilizes rotational energy to store and release electricity. 1. It operates on the principle of inertia, which allows

Get a quote

Energy Storage Flywheel Electromagnetic Field: The Future of

Why Flywheel Energy Storage Is Stealing the Spotlight Imagine a technology that stores energy like a spinning top—simple, fast, and incredibly efficient. That''s flywheel energy storage for

Get a quote

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel energy storage is an exciting solution for efficient and sustainable energy management. This innovative technology offers high efficiency and substantial environmental

Get a quote

The Flywheel Energy Storage System: A Conceptual Study,

The Flywheel energy storage approach is currently considered as one of the most successful figures of energy storage, and many attempts have been made to improve this technology.

Get a quote

Flywheel Energy Storage System for Electric Start and an All

Flywheel technology overcomes some of the shortcomings of today''s energy storage systems by having an extremely high cyclic-life, limited temperature sensitivity, no chemical hazards,

Get a quote

Overview of Flywheel Systems for Renewable Energy

Energy can be stored through various forms, such as ultra-capacitors, electrochemical batteries, kinetic flywheels, hydro-electric power or compressed air. Their comparison in terms of specific

Get a quote

What is the self-discharge rate of flywheel energy storage?

The self-discharge rate of flywheel energy storage refers to the proportion of stored energy that a flywheel loses to its surroundings over time without any external load being applied.

Get a quote

The most complete analysis of flywheel energy

Flywheel energy storage is an energy storage technology with high power density, high reliability, long life, and environmental friendliness. It

Get a quote

Flywheel Energy Storage: A Comprehensive Guide

Introduction to Flywheel Energy Storage Flywheel energy storage (FES) is a kinetic energy storage technology that utilizes a rotating flywheel to store energy. The flywheel is

Get a quote

Flywheel energy and power storage systems

Small-scale flywheel energy storage systems have relatively low specific energy figures once volume and weight of containment is comprised. But the high specific power

Get a quote

6 FAQs about [When the flywheel energy storage is discharged the flywheel acts as]

How does Flywheel energy storage work?

Flywheel energy storage (FES) works by accelerating a rotor (flywheel) to a very high speed and maintaining the energy in the system as rotational energy.

What is the operational mechanism of a flywheel?

The operational mechanism of a flywheel has two states: energy storage and energy release. Energy is stored in a flywheel when torque is applied to it. The torque increases the rotational speed of the flywheel; as a result, energy is stored. Conversely, the energy is released in the form of torque to the connected mechanical device .

Why do flywheel energy storage systems have a high speed?

There are losses due to air friction and bearing in flywheel energy storage systems. These cause energy losses with self-discharge in the flywheel energy storage system. The high speeds have been achieved in the rotating body with the developments in the field of composite materials.

What is the function of a flywheel?

The basic function of the flywheel is to convert the mechanical energy for the end-use application, which is electrical energy. For this conversion, an electromechanical machine is required which could be a motor/generator set. Generator and motor: When the kinetic energy is being stored, the motor is used to drive the flywheel.

How kinetic energy is stored in a flywheel?

In this storage scheme, kinetic energy is stored by spinning a disk or rotor about its axis. Amount of energy stored in disk or rotor is directly proportional to the square of the wheel speed and rotor׳s mass moment of inertia. Whenever power is required, flywheel uses the rotor inertia and converts stored kinetic energy into electricity .

How long does a flywheel energy storage system last?

Flywheel energy storage systems have a long working life if periodically maintained (>25 years). The cycle numbers of flywheel energy storage systems are very high (>100,000). In addition, this storage technology is not affected by weather and climatic conditions . One of the most important issues of flywheel energy storage systems is safety.

Guess what you want to know

-

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

-

Malawi 100MW flywheel energy storage

Malawi 100MW flywheel energy storage

-

Korea flywheel energy storage hybrid power supply

Korea flywheel energy storage hybrid power supply

-

Flywheel energy storage energy cost

Flywheel energy storage energy cost

-

Superconducting flywheel energy storage cost

Superconducting flywheel energy storage cost

-

Huawei s Largest Flywheel Energy Storage Project

Huawei s Largest Flywheel Energy Storage Project

-

Burkina Faso 50MW flywheel energy storage

Burkina Faso 50MW flywheel energy storage

-

Flywheel energy storage 5MWH liquid cooling installation

Flywheel energy storage 5MWH liquid cooling installation

-

Processing flywheel energy storage

Processing flywheel energy storage

-

Energy storage flywheel weight

Energy storage flywheel weight

Industrial & Commercial Energy Storage Market Growth

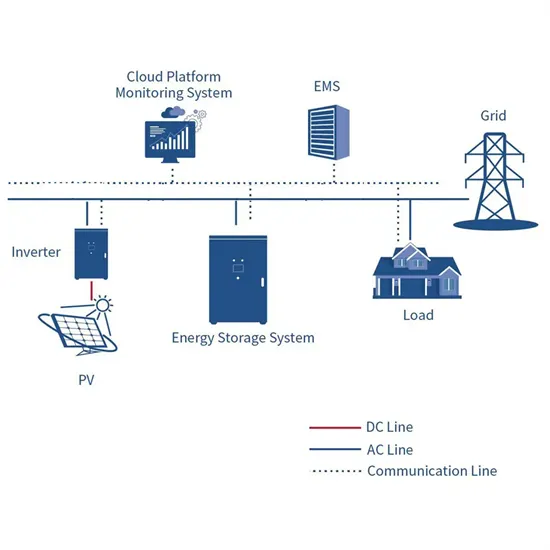

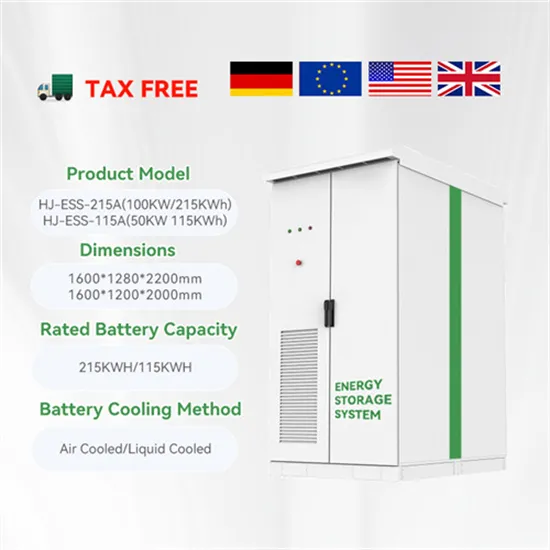

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.