What are the benefits of a lightweight flywheel and why aren''t they

This previous question explains what a flywheel does and why it is needed. That explanation means that the flywheel needs a certain amount of mass to do its job. However,

Get a quote

$200 Million For Renewables-Friendly Flywheel Energy Storage

1 day ago· The US startup Torus Energy combines flywheel technology with 21st century battery chemistry in one advanced energy storage system

Get a quote

Flywheel energy storage for grid frequency regulation

Flywheel energy storage systems represent a critical technology for grid frequency regulation and short-duration energy storage, offering unique advantages in high power density and rapid

Get a quote

A Review of Flywheel Energy Storage System

The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind

Get a quote

Flywheel Removal with Threaded Puller versus "Hitting" the

So, as I am waiting for my new flywheel removal tool to come in, I''ve come across quite a few videos where people hammer on the crankshaft end (flywheel side) with the nut

Get a quote

Help w/Removing Flywheel Homelite Super-XL

The flywheel is the thickest at these points and can take a hit from a punch if common sense is applied. I have done it so I know it works. If it didn''t have a puller to get at

Get a quote

If my starter is spinning but not engaging flywheel, what is the issue?

The solenoid pushes a little gadget that engages with the flywheel / flex plate, so that when the starter spins, it turns the motor. If you just hear a whirring sound like the starter

Get a quote

flywheel magnet question

The flywheel seems to have some sort of thin metal one one side that appears to be a magnet. The opposite side looks to be missing this strip. The magnets aren''t on opposite

Get a quote

Flywheel magnet testing

Flywheel magnets I should have been more specific. I''m testing the magnet strenth off the saw. I read that a flywheel should attract steel at 1" distance.This isn''t and has nothing

Get a quote

Inertia Emulation by Flywheel Energy Storage System for

By regulating the speed of the flywheel in proportion to the grid frequency, the flywheel serves as an energy buffer that absorbs and releases its kinetic energy to provide inertia support.

Get a quote

Flywheel Energy Storage System: A Breakthrough in Power

Flywheel energy storage systems stand out among frequency regulators as worthy contenders. Its function lies in equalizing the power supply and demand cycles to maintain

Get a quote

A review of flywheel energy storage systems: state of the art

This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Get a quote

A review of control strategies for flywheel energy storage system

The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

Get a quote

Has Anyone Ever Seen a Bad Flywheel Cause No Spark?

The darn thing has no spark. I figured a bad coil, but much to my surprise, if I swapped a different flywheel in, the saw had spark. The flywheel has a broken fin that did

Get a quote

064 / 066 / MS660 18 flywheels, 7 coils

QUESTION - I have a flywheel 1203/1204 with a single keyway, when I line up the magnets with a dual keyway 1203 flywheel the single keyway lines up with the 1:00 keyway

Get a quote

Thermal power-flywheel energy storage combined frequency

In order to improve the frequency stability of the AC-DC hybrid system under high penetration of new energy, the suitability of each characteristic of flywheel energy storage to participate in

Get a quote

Applications of flywheel energy storage system on load frequency

Download Citation | On Jan 1, 2024, Weiming Ji and others published Applications of flywheel energy storage system on load frequency regulation combined with various power

Get a quote

ARRA SGDP Hazle Spindle (20 MW Flywheel

The project objective was to design, build, and operate a flywheel energy storage frequency regulation plant at the Humboldt Industrial Park in Hazle Township, Pennsylvania.

Get a quote

Applications of flywheel energy storage system on load frequency

Despite the initial high capital costs, the appeal of flywheel arrays and flywheel-hybrid energy storage systems lies in their attractiveness for participating in frequency

Get a quote

Grid-Scale Flywheel Energy Storage Plant

The plant will provide a response time of less than four seconds to frequency changes. With availability of more than 97%, as demonstrated in earlier small-scale pilots, this technology

Get a quote

Thermal power-flywheel energy storage combined frequency

In order to improve the frequency stability of the AC-DC hybrid system under high penetration of new energy, the suitability of each characteristic of flywheel

Get a quote

What does a flywheel do and what is it connected to?

A flywheel serves four main purposes (in most vehicles): It provides mass for rotational inertia to keep the engine in motion It is specifically weighted to provide balance for

Get a quote

Analysis of Flywheel Energy Storage Systems for Frequency

However, with AC to DC converters, the flywheel energy storage system (FESS) is no longer tied to operate at the grid frequency. FESSs have high energy density, durability,

Get a quote

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

This article proposed a compact and highly efficient flywheel energy storage system (FESS). Single coreless stator and double rotor structures are used to eliminate the idling loss caused

Get a quote

Research on Grid-Forming Flywheel Energy Storage-Supported Frequency

As the penetration rate of renewable energy rapidly increases, power systems are facing challenges such as reduced inertia and weakened frequency stability. New energy units,

Get a quote

Hybrid Energy Storage System with Doubly Fed Flywheel and

Doubly-fed flywheel is a short-time energy storage system with 50 ms or even lower response time, million charge/discharge cycle life, suitable for high frequency charging

Get a quote

Optimal Configuration of Flywheel–Battery Hybrid

The integration of energy storage systems is an effective solution to grid fluctuations caused by renewable energy sources such as wind power

Get a quote

Flywheels Energy Storage Systems

Flywheel Energy Storage Systems (FESS) offer a mature solution for enhancing stability, frequency control and voltage regulation in electrical systems, leveraging kinetic energy stored

Get a quote

How to stop flywheel from spinning without special tools?

How do I stop the flywheel from spinning while torquing the bolts? My repair manual says I should buy a special tool to do it, but I don''t want to buy an expensive tool that I''ll rarely use. Is th...

Get a quote

Analysis of Flywheel Energy Storage Systems for Frequency

Flywheels have been used to store energy in rotation for centuries. However, they were previously not suited for storing electrical energy because of their lower operating speed.

Get a quote

Flywheel Energy Storage Assisted Frequency Regulation in

As renewable energy forms a larger portion of the energy mix, the power system experiences more intricate frequency fluctuations. Flywheel energy storage techno.

Get a quote

Flywheel energy storage controlled by model predictive control to

The use of energy storage systems to improve the fluctuation of wind power generation has garnered significant in the development of wind power. However, the

Get a quote

Design of an adaptive frequency control for flywheel energy storage

Frequency fluctuations are brought on by power imbalances between sources and loads in microgrid systems. The flywheel energy storage system (FESS) can mitigate the

Get a quote

Flywheel Energy Storage System: A Breakthrough in Power Frequency

Flywheel energy storage systems stand out among frequency regulators as worthy contenders. Its function lies in equalizing the power supply and demand cycles to maintain

Get a quote

A Case Study on Flywheel Energy Storage System Application for

Flywheel energy storage system (FESS) is an attractive technology owing to its main advantages of high energy density, long life cycle and cleanliness, and is suitable for a short-term power

Get a quote

Flywheels Energy Storage Systems

Flywheel Energy Storage Systems (FESS) offer a mature solution for enhancing stability, frequency control and voltage regulation in electrical systems,

Get a quote

6 FAQs about [Flywheel energy storage frequency]

Do flywheel energy storage systems provide fast and reliable frequency regulation services?

Throughout the process of reviewing the existing FESS applications and integration in the power system, the current research status shows that flywheel energy storage systems have the potential to provide fast and reliable frequency regulation services, which are crucial for maintaining grid stability and ensuring power quality.

What is a flywheel energy storage system (fess)?

Frequency fluctuations are brought on by power imbalances between sources and loads in microgrid systems. The flywheel energy storage system (FESS) can mitigate the power imbalance and suppress frequency fluctuations.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is the difference between flywheel and battery energy storage system?

Compared to battery energy storage system, flywheel excels in providing rapid response times, making them highly effective in managing sudden frequency fluctuations, while battery energy storage system, with its ability to store large amounts of energy, offers sustained response, maintaining stability .

What is a flywheel energy storage unit?

A flywheel energy storage unit is a mechanical system designed to store and release energy efficiently. It consists of a high-momentum flywheel, precision bearings, a vacuum or low-pressure enclosure to minimize energy losses due to friction and air resistance, a motor/generator for energy conversion, and a sophisticated control system.

Can a flywheel store energy?

Flywheels have been used to store energy in rotation for centuries. However, they were previously not suited for storing electrical energy because of their lower operating speed. tied to operate at the grid frequency. FESSs have high energy density, durability, and can be cycled frequently without impacting performance.

Guess what you want to know

-

Does the flywheel energy storage frequency have the same

Does the flywheel energy storage frequency have the same

-

Flywheel energy storage frequency

Flywheel energy storage frequency

-

Effective range of Malta flywheel energy storage

Effective range of Malta flywheel energy storage

-

120kw Flywheel Energy Storage

120kw Flywheel Energy Storage

-

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

-

Flywheel energy storage is considered perpetual motion

Flywheel energy storage is considered perpetual motion

-

What does flywheel energy storage consist of

What does flywheel energy storage consist of

-

Cape Verde Energy Storage Flywheel

Cape Verde Energy Storage Flywheel

-

Kiribati Flywheel Energy Storage System

Kiribati Flywheel Energy Storage System

-

GlobalFoundries Flywheel Energy Storage

GlobalFoundries Flywheel Energy Storage

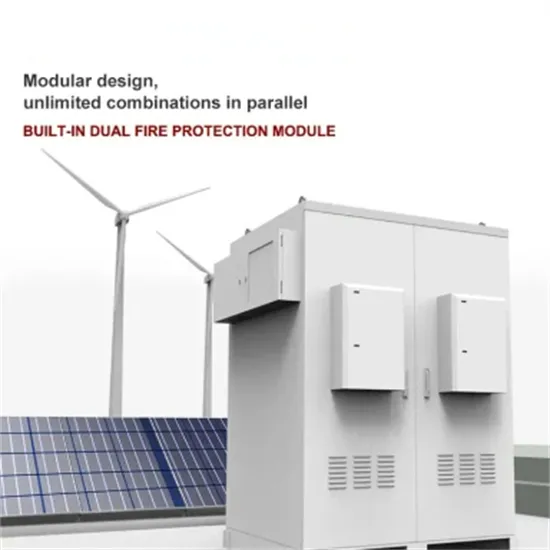

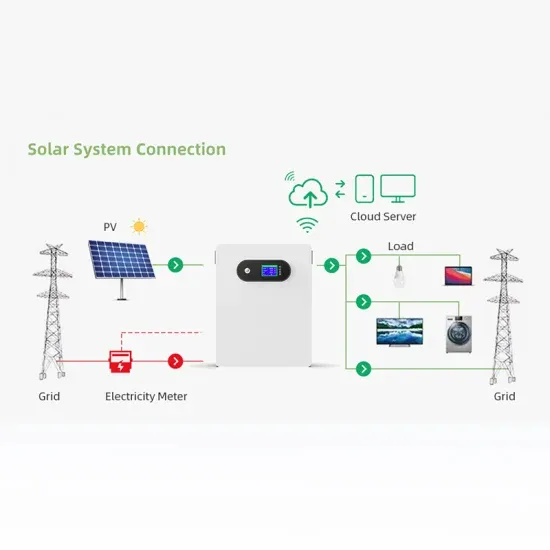

Industrial & Commercial Energy Storage Market Growth

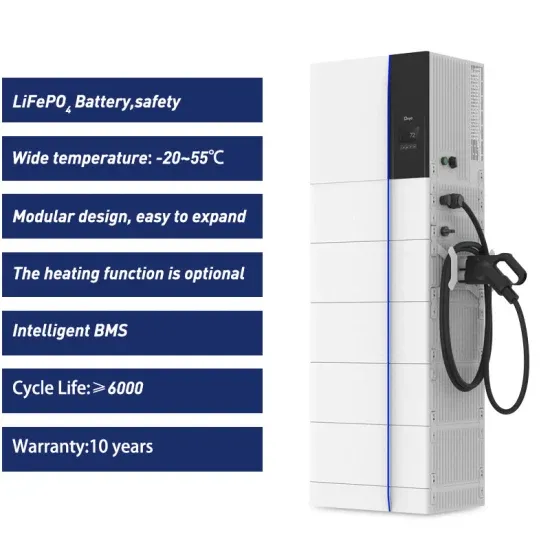

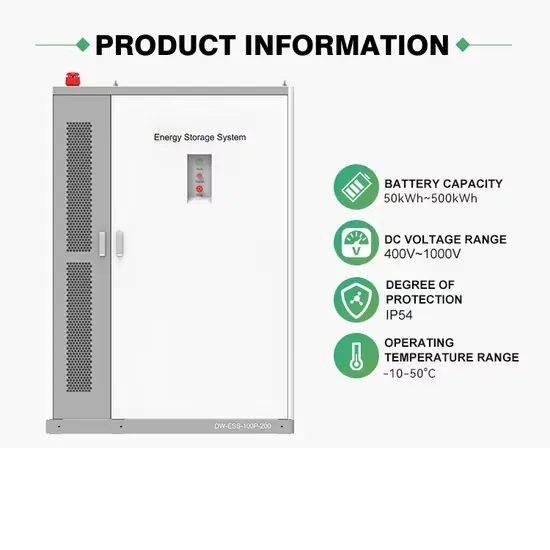

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.