Flywheels | Climate Technology Centre & Network | Tue, 11/08/2016

In this case, the second flywheel picks up when the first one is done discharging and is followed by the third, etc. Comparison with other energy storage technologies. To use flywheel

Get a quote

The Flywheel Energy Storage System: A Conceptual Study,

Many storage technologies have been developed in an attempt to store the extra AC power for later use. Among these technologies, the Flywheel Energy Storage (FES) system has

Get a quote

Flywheel Energy Storage: A Comprehensive Guide

FES has a high power density and fast response time, making it suitable for applications that require rapid charging and discharging. However, its energy storage capacity

Get a quote

Flywheel Energy Storage Systems and Their

This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Get a quote

Flywheel energy storage systems: A critical review on

Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical network is easily feasible. The balance in

Get a quote

How much wattage does the flywheel energy storage motor have

A flywheel energy storage system employed by NASA (Reference: wikipedia ) How Flywheel Energy Storage Systems Work? Flywheel energy storage systems employ kinetic energy

Get a quote

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get a quote

Applications of flywheel energy storage system on load frequency

Notably, FESS finds an instrumental role in load frequency regulation, involving the adjustment of power system frequency and output to match the demand. Load frequency

Get a quote

A cross-entropy-based synergy method for capacity

Flywheel energy storage system coupled with thermal power unit is one of the important means to solve the problem of frequency regulation [9]. Recently, numerous studies

Get a quote

The Status and Future of Flywheel Energy Storage

The core element of a flywheel consists of a rotating mass, typically axisymmetric, which stores rotary kinetic energy E according to (Equation 1) E = 1 2 I ω 2 [J], where E is the

Get a quote

Temporal Power, Flywheel Energy Storage – H.H.

Temporal PowerFlywheel Energy Storage"With thorough project management and smart engineering by the Angus team, they have been able to condense

Get a quote

Analysis of Flywheel Energy Storage Systems for Frequency

Analysis of Flywheel Energy Storage Systems for Frequency Support by Tanner Grider A thesis submitted to the Graduate Faculty of Auburn University in partial fulfillment of

Get a quote

How flywheel energy storage works

principle of rotating mass causes energy to store in a flywheel by converting electrical energy into mechanical energy in the form of rotational kinetic energy. 39 The energy fed to an FESS is

Get a quote

Technology: Flywheel Energy Storage

Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000

Get a quote

What is a flywheel energy storage? | NenPower

Flywheel energy storage is a technology that utilizes a rotating mass to store energy kinetically and release it when required. 1. It operates

Get a quote

Flywheel Energy Storage Systems (FESS)

Flywheel energy storage systems (FESS) use electric energy input which is stored in the form of kinetic energy. Kinetic energy can be described as

Get a quote

Grid-Scale Flywheel Energy Storage Plant

Demonstrating frequency regulation using flywheels to improve grid performance Beacon Power will design, build, and operate a utility-scale 20 MW flywheel energy storage plant at the

Get a quote

Flywheel Energy Storage System: What Is It and How Does It

While battery storage remains the dominant choice for long-term energy storage, flywheel systems are well-suited for applications requiring rapid energy release and frequent cycling.

Get a quote

The most complete analysis of flywheel energy

This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other

Get a quote

The role of flywheel energy storage in decarbonised

The best choice is the lowest cost technology with low minutes of storage and flywheels fit this perfectly. A flywheel is a very simple device, storing energy in

Get a quote

Flywheel Energy Storage Systems (FESS)

Advanced FESS operate at a rotational frequency in excess of 100,000 RPM with tip speeds in excess of 1000 m/s. FESS are best used for high power, low energy applications that require

Get a quote

Analysis of Flywheel Energy Storage Systems for Frequency

However, with AC to DC converters, the flywheel energy storage system (FESS) is no longer tied to operate at the grid frequency. FESSs have high energy density, durability,

Get a quote

Flywheel Energy Storage System: What Is It and How

While battery storage remains the dominant choice for long-term energy storage, flywheel systems are well-suited for applications requiring rapid energy

Get a quote

Overview of Flywheel Systems for Renewable Energy

son in terms of specific power, specific energy, cycle life, self-discharge rate and efficiency can be found, for example, in [3]. Compared with other energy storage methods, notably chemical

Get a quote

6 FAQs about [Does the flywheel energy storage frequency have the same]

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

Do flywheel energy storage systems provide fast and reliable frequency regulation services?

Throughout the process of reviewing the existing FESS applications and integration in the power system, the current research status shows that flywheel energy storage systems have the potential to provide fast and reliable frequency regulation services, which are crucial for maintaining grid stability and ensuring power quality.

What is a flywheel energy storage system?

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher tensile strength than steel and can store much more energy for the same mass. To reduce friction, magnetic bearings are sometimes used instead of mechanical bearings.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

Are flywheels better than batteries?

Lifespan: Flywheels tend to last much longer than batteries, especially for high-cycle applications. Suitability for Short-Term Energy Needs: Flywheels excel in managing short-term energy surges or imbalances, while batteries are often better for long-term storage. Which Is Better: Flywheel or Battery Energy Storage?

Can a flywheel store energy?

Flywheels have been used to store energy in rotation for centuries. However, they were previously not suited for storing electrical energy because of their lower operating speed. tied to operate at the grid frequency. FESSs have high energy density, durability, and can be cycled frequently without impacting performance.

Guess what you want to know

-

Does the flywheel energy storage frequency have the same

Does the flywheel energy storage frequency have the same

-

Flywheel energy storage frequency

Flywheel energy storage frequency

-

Effective range of Malta flywheel energy storage

Effective range of Malta flywheel energy storage

-

Flywheel energy storage fire protection design

Flywheel energy storage fire protection design

-

Enterprises producing flywheel energy storage in Liberia

Enterprises producing flywheel energy storage in Liberia

-

Flywheel energy storage is considered perpetual motion

Flywheel energy storage is considered perpetual motion

-

What does flywheel energy storage consist of

What does flywheel energy storage consist of

-

Cape Verde Energy Storage Flywheel

Cape Verde Energy Storage Flywheel

-

Kiribati Flywheel Energy Storage System

Kiribati Flywheel Energy Storage System

-

Flywheel Energy Storage Power Station Topology

Flywheel Energy Storage Power Station Topology

Industrial & Commercial Energy Storage Market Growth

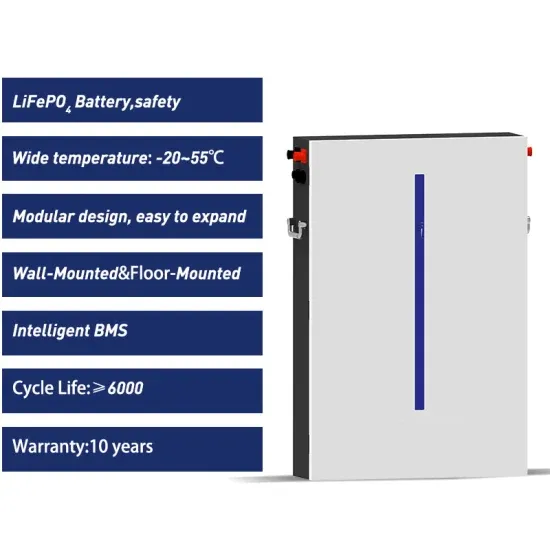

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.