Movable flywheel energy storage system

A flywheel energy storage and housing technology, applied in the field of flywheel energy storage, can solve the problems of reduced energy consumption, troublesome disassembly and

Get a quote

飞轮储能系统电机转子散热研究进展

Finally, a fresh hollow shaft flow cooling system is put forth to solve the heat dissipation issue in MW FESS MG rotor cooling. Key words: flywheel energy

Get a quote

Flywheel Energy Storage Systems | Electricity Storage Units

This flywheel, when paired to a motor/generator unit, behaves like a battery and energy can be stored for hours and dispatched on demand. The system service life is 20 years, without limits

Get a quote

A review of flywheel energy storage systems: state of the art

This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Get a quote

Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components, characteristics, applications,

Get a quote

Flywheel energy storage and heat dissipation

heat dissipation In this research, the effects of the heat pipes arrangement as a passive cooling system in an electric motor for the flywheel energy storage application were analysed. Two

Get a quote

Fly wheel energy storage rotor vacuum heat radiation system

A flywheel energy storage and heat dissipation system technology, applied in the field of flywheel energy storage rotor heat dissipation system, can solve problems such as heat dissipation

Get a quote

Analysis and design on stator heat dissipation of motor in flywheel

This simple and efficient design method provides a reference for the development of stator cooling systems for flywheel energy storage applications. Key words: flywheel energy storage, motor

Get a quote

Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components,

Get a quote

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get a quote

Flywheel energy storage

OverviewMain componentsPhysical characteristicsApplicationsComparison to electric batteriesSee alsoFurther readingExternal links

A typical system consists of a flywheel supported by rolling-element bearing connected to a motor–generator. The flywheel and sometimes motor–generator may be enclosed in a vacuum chamber to reduce friction and energy loss. First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors

Get a quote

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel technology is a sophisticated energy storage system that uses a spinning wheel to store mechanical energy as rotational energy. This system ensures high energy

Get a quote

The most complete analysis of flywheel energy

This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other

Get a quote

CN215419967U

The utility model relates to the technical field of flywheel energy storage systems, and particularly discloses a heat dissipation structure for a flywheel energy storage unit. The utility model can

Get a quote

Flywheel easy to dissipate heat and flywheel energy storage system

A flywheel and heat sink technology, applied in the direction of flywheel, mechanical energy control, electromechanical devices, etc., can solve the problems of high inner ring

Get a quote

Heat energy dissipation device for a flywheel energy storage

The present invention relates generally to flywheel energy storage systems, and more particularly to devices, and methods for dissipating the heat energy developed during operation of...

Get a quote

CN115411886A

The invention provides a magnetic suspension energy storage flywheel and energy storage equipment with an active heat dissipation function, which comprise a base, a first energy

Get a quote

Flywheel Energy Storage: A High-Efficiency Solution

Flywheel technology is a sophisticated energy storage system that uses a spinning wheel to store mechanical energy as rotational energy. This

Get a quote

Numerical study of jet impingement cooling methods for improving heat

Flywheel energy storage systems (FESS) have garnered a lot of attention because of their large energy storage and transient response capability. Due to the limited space and

Get a quote

CN116388447A

The invention relates to the technical field of flywheel energy storage devices, in particular to a multi-stage centrifugally driven flow-enhanced cooling device in a rotor shaft and a flywheel

Get a quote

CN216390739U

The utility model provides a flywheel energy storage rotor heat dissipation mechanism and a flywheel energy storage system, wherein the heat dissipation mechanism comprises a first

Get a quote

A review of flywheel energy storage systems: state of the art and

There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the

Get a quote

A review of flywheel energy storage systems: state of the art

The ex-isting energy storage systems use various technologies, including hydro-electricity, batteries, supercapacitors, thermal storage, energy storage flywheels,[2] and others.

Get a quote

The most complete analysis of flywheel energy storage for new energy

This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other aspects.

Get a quote

Case study on flywheel energy storage systems: LPTN-based

The basic principle involves storing energy using a rotating flywheel and achieving the conversion between mechanical energy and electrical energy through a reversible

Get a quote

Design of Flywheel Energy Storage System – A Review

This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens.

Get a quote

Case study on flywheel energy storage systems: LPTN-based

This study established a lumped parameter thermal network model for vertical flywheel energy storage systems, considering three critical gaps in conventional thermal

Get a quote

Guess what you want to know

-

Mainstream heat dissipation methods for energy storage devices

Mainstream heat dissipation methods for energy storage devices

-

Composition of flywheel energy storage device

Composition of flywheel energy storage device

-

Energy storage system heat dissipation

Energy storage system heat dissipation

-

Flywheel energy storage device for photovoltaic

Flywheel energy storage device for photovoltaic

-

Flywheel energy storage device and enterprises

Flywheel energy storage device and enterprises

-

Which flywheel energy storage device is the most expensive

Which flywheel energy storage device is the most expensive

-

Benefits of flywheel energy storage power stations

Benefits of flywheel energy storage power stations

-

Energy storage device conversion efficiency

Energy storage device conversion efficiency

-

Monaco home energy storage device

Monaco home energy storage device

-

15-degree photovoltaic inverter energy storage integrated device

15-degree photovoltaic inverter energy storage integrated device

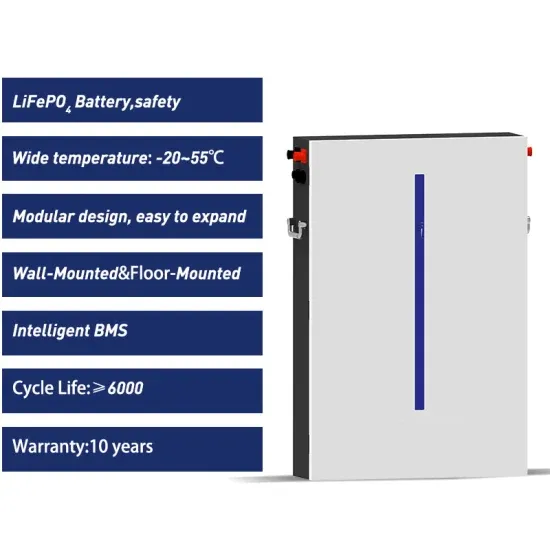

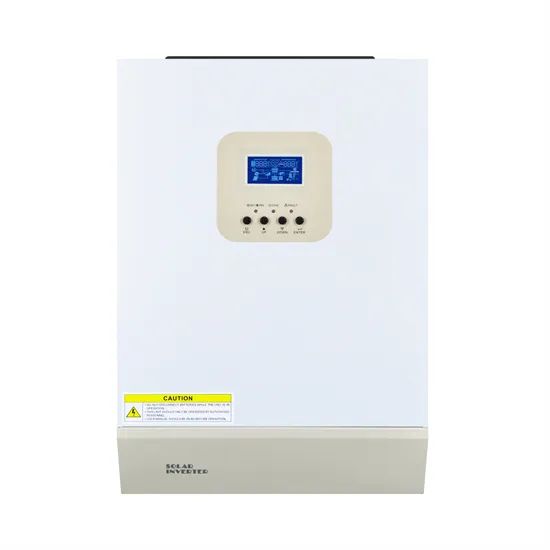

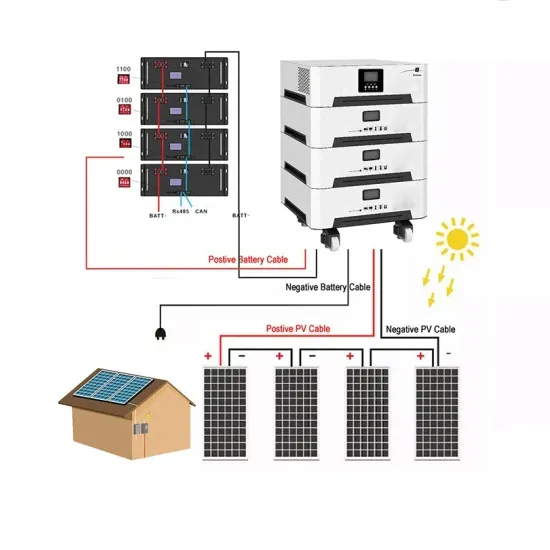

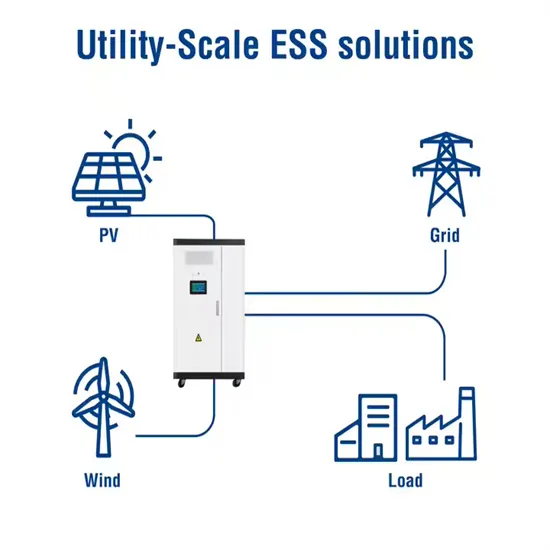

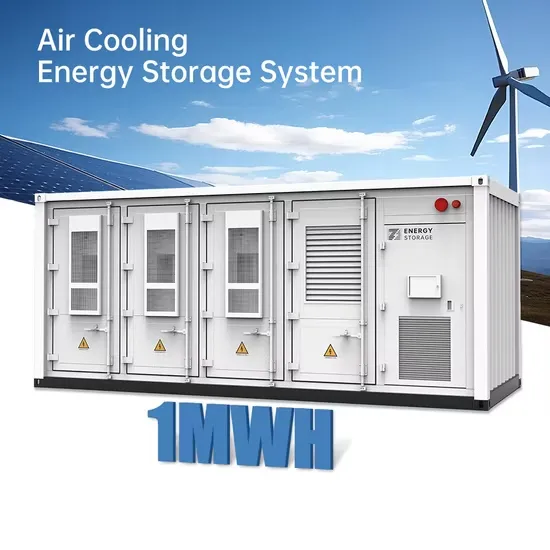

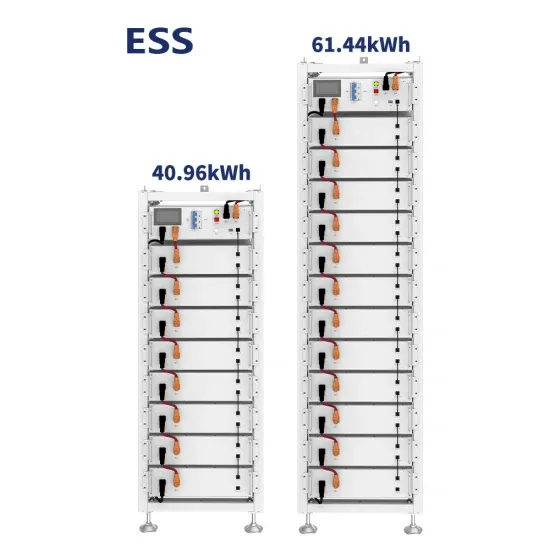

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

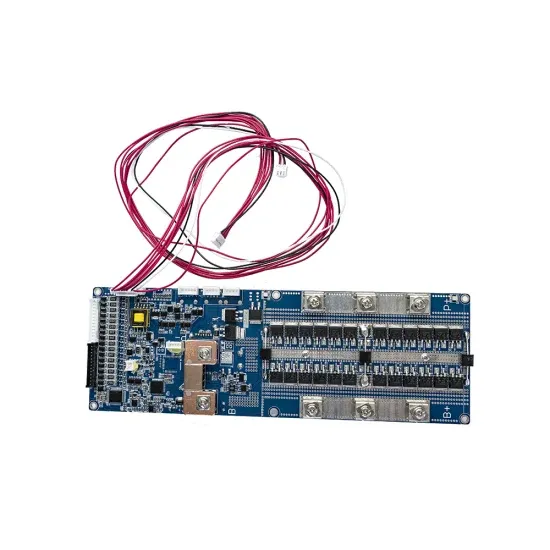

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.