The development of a techno-economic model for the

The composite rotor flywheel energy storage system costs more than the steel rotor flywheel energy storage system because composite materials are still in the research and

Get a quote

RotorVault Energy Storage Cost Analysis and Flywheel Price

RotorVault''s storage product for data center applications is the most cost-competitive solution offering both backup power for critical IT and active power conditioning. When technologies

Get a quote

The Flywheel Energy Storage System: A Conceptual Study,

The Flywheel energy storage approach is currently considered as one of the most successful figures of energy storage, and many attempts have been made to improve this technology.

Get a quote

Flywheel energy storage

There is a class distinction between flywheels used for smoothing the intermittent output of an engine or load on a machine to those designed to store energy for a distinct

Get a quote

Flywheels | Climate Technology Centre & Network | Tue, 11/08/2016

The rotor, as the energy storage mechanism, is the most important component of the flywheel energy storage system. The design of the rotor is the most significant contributor to the

Get a quote

RotorVault Energy Storage Cost Analysis and Flywheel Price

RotorVault Flywheel Cost-Competitive Technology RotorVault''s storage product for data center applications is the most cost-competitive solution offering both backup power for critical IT and

Get a quote

A review of flywheel energy storage systems: state of the art

The lithium-ion battery has a high energy density, lower cost per energy capacity but much less power density, and high cost per power capacity. This explains its popularity in

Get a quote

Flywheel Energy Storage

DC flywheel energy storage maintenance requirements vary depending on the specific flywheel design features, but are generally less frequent and less expensive than for batteries.

Get a quote

Flywheel Energy Storage Systems and Their

This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Get a quote

Flywheel Energy Storage Costs Decoded: A 2024 Price Analysis

NASA''s 2023 lunar base prototype used flywheels storing energy at $780/kWh - 22% cheaper than their moon-grade lithium batteries. Closer to Earth, Tesla''s Texas factory

Get a quote

How much does a flywheel energy storage device cost

The costs of composite and steel rotor flywheels are $190 and $146/MWh, respectively. Flywheel energy storage systems are increasingly being considered as a promising alternative

Get a quote

How much does a flywheel energy storage system cost?

The examination of flywheel energy storage systems reveals a complex interplay of factors influencing their pricing and application. Ranging

Get a quote

[OC] Most cost-competitive technologies for energy storage

It shows you what technology is best suited for different applications of energy storage, depending how long you want to store energy and how often you want to use your

Get a quote

A review of flywheel energy storage systems: state of the art and

There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the

Get a quote

What is the price of flywheel energy storage? | NenPower

When considering the cost of flywheel energy storage relative to other storage technologies, such as lithium-ion batteries, the differences can be significant. Flywheel

Get a quote

ENERGY CONSERVATION WITH FLYWHEELS

ENERGY CONSERVATION WITH FLYWHEELS Like the electric storage battery, the flywheel stores energy; but unlike any known battery, the flywheel can accept or deliver this energy at

Get a quote

Review of Flywheel Energy Storage Systems structures and applications

Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an

Get a quote

DOE ESHB Chapter 7 Flywheels

For thousands of years, some form of flywheel technology has been used to smooth the flow of energy in rotating machinery from small, hand-held devices to the largest engines [1].

Get a quote

Comprehensive review of energy storage systems technologies,

Battery, flywheel energy storage, super capacitor, and superconducting magnetic energy storage are technically feasible for use in distribution networks. With an energy density

Get a quote

Flywheel Energy Storage Systems: A Critical Review on

Summary Energy storage systems (ESSs) are the technologies that have driven our society to an extent where the management of the electrical network is easily feasible. The balance in

Get a quote

What is a flywheel?

A flywheel is a mechanical device that stores rotational energy. It''s essentially a heavy wheel designed to resist changes in its rotational speed, making it useful for smoothing out power

Get a quote

The flywheel is actually an energy storage device

How does a flywheel energy storage system work? Flywheel energy storage uses electric motorsto drive the flywheel to rotate at a high speed so that the electrical power is transformed

Get a quote

What is the price of flywheel energy storage?

When considering the cost of flywheel energy storage relative to other storage technologies, such as lithium-ion batteries, the differences can

Get a quote

How much does a flywheel energy storage system cost?

The examination of flywheel energy storage systems reveals a complex interplay of factors influencing their pricing and application. Ranging from initial investment estimates of

Get a quote

Flywheel Energy Storage Costs: Breaking Down the Economics

Breaking down a typical $1.2 million/MW flywheel installation: The good news? Material science breakthroughs are driving down the most expensive components. Take carbon fiber prices -

Get a quote

[OC] Most cost-competitive technologies for energy

It shows you what technology is best suited for different applications of energy storage, depending how long you want to store energy

Get a quote

Understanding the Cost of Flywheel Energy Storage Systems: A

Their 20MW flywheel array provides frequency regulation at 90% efficiency, outperforming chemical batteries in response time. The upfront cost of flywheel energy storage

Get a quote

6 FAQs about [Which flywheel energy storage device is the most expensive ]

Are flywheel energy storage systems economically feasible?

Equipment cost distribution for the flywheel energy storage systems. FESSs are used for short-duration power applications. Therefore, power capital cost ($/kW) could be a useful parameter to compare the economic feasibility of energy storage systems for similar power applications.

How can flywheels be more competitive to batteries?

The use of new materials and compact designs will increase the specific energy and energy density to make flywheels more competitive to batteries. Other opportunities are new applications in energy harvest, hybrid energy systems, and flywheel’s secondary functionality apart from energy storage.

What is the largest flywheel energy storage?

The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration . Utility-scale flywheel storage is typically used for frequency regulation to maintain grid frequency by matching electricity supply and demand for a short period, usually 15 min , .

What is the power rating of a flywheel energy storage system?

Utility-scale energy storage systems for stationary applications typically have power ratings of 1 MW or more . The largest flywheel energy storage is in New York, USA by Beacon Power with a power rating of 20 MW and 15 min discharge duration .

Does a flywheel storage system need a bottom-up research?

However, almost no bottom-up research has been done, i.e., research that considers the technical parameters to size the components of a flywheel storage system, estimate cost parameters based on the design, and provide a probable distribution of the total investment cost and levelized cost of storage.

What is a flywheel/kinetic energy storage system (fess)?

Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently.

Guess what you want to know

-

Flywheel energy storage device and enterprises

Flywheel energy storage device and enterprises

-

Which projects are suitable for flywheel energy storage installation

Which projects are suitable for flywheel energy storage installation

-

Flywheel energy storage and heat dissipation device

Flywheel energy storage and heat dissipation device

-

Composition of flywheel energy storage device

Composition of flywheel energy storage device

-

Which company in Peru is using flywheel energy storage

Which company in Peru is using flywheel energy storage

-

Which type of energy storage does the charging pile belong to

Which type of energy storage does the charging pile belong to

-

Gravity flywheel inertial energy storage power generation

Gravity flywheel inertial energy storage power generation

-

Flywheel large-scale energy storage

Flywheel large-scale energy storage

-

Mechanical flywheel energy storage

Mechanical flywheel energy storage

-

Flywheel Energy Storage Power Supply

Flywheel Energy Storage Power Supply

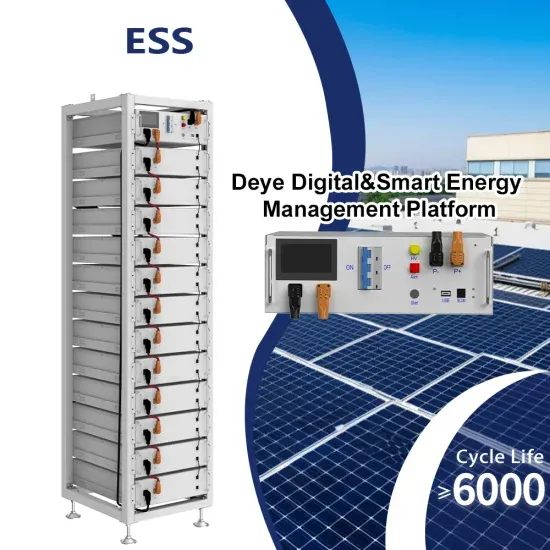

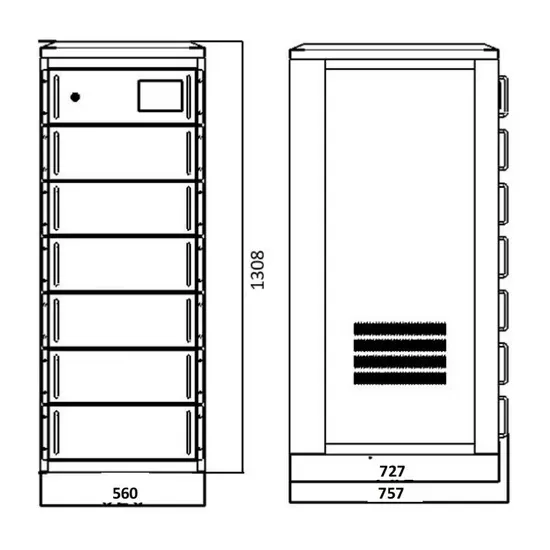

Industrial & Commercial Energy Storage Market Growth

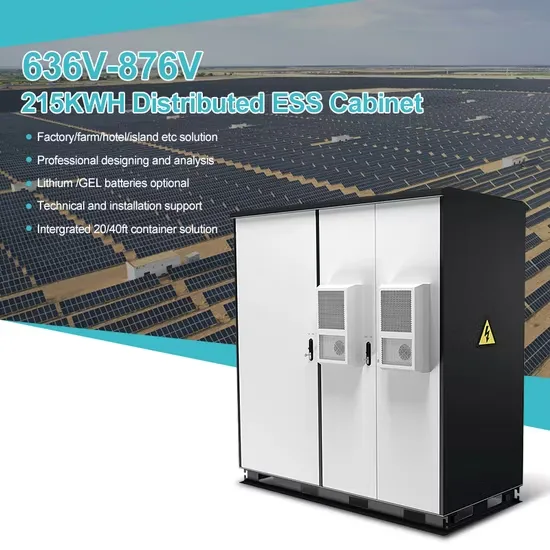

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.