Distributed fixed-time cooperative control for flywheel energy storage

This paper studies the cooperative control problem of flywheel energy storage matrix systems (FESMS). The aim of the cooperative control is to achieve

Get a quote

What is the self-discharge rate of flywheel energy storage?

The self-discharge rate of flywheel energy storage systems typically ranges between 1% to 5% per hour. This low rate is significant when compared to traditional batteries,

Get a quote

Modeling flywheel energy storage system charge and

Here, we focus on some of the basic properties of flywheel energy storage systems, a technology that becomes competitive due to recent

Get a quote

UPS Energy Storage Option 4: Flywheels

A flywheel device contains a rotary flywheel that spins at speeds of 37,000 RPM, converting electrical energy into stored kinetic energy. In a UPS application, if a power outage

Get a quote

Technology: Flywheel Energy Storage

Summary of the storage process Flywheel Energy Storage Systems (FESS) rely on a mechanical working principle: An electric motor is used to spin a rotor of high inertia up to 20,000-50,000

Get a quote

A review of flywheel energy storage systems: state of the art and

The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

Get a quote

Flywheel Energy Storage System: What Is It and How

Rapid Charge/Discharge: Flywheels can charge and discharge electricity much faster than traditional batteries, making them ideal for balancing power grids or

Get a quote

Flywheel Technology – Zhang''s Research Group

Flywheels are typically not suitable for supplying bulk power to the grid, as they generally store energy for shorter durations than desired for such large scale application. Consequently, much

Get a quote

Beacon Power

Beacon flywheel storage systems have much faster ramp rates than traditional generation and can correct imbalances sooner with much greater accuracy and efficiency. In fact, Beacon

Get a quote

Flywheel Technology – Zhang''s Research Group

Flywheels are typically not suitable for supplying bulk power to the grid, as they generally store energy for shorter durations than desired for such large scale

Get a quote

The Status and Future of Flywheel Energy Storage

Outline Flywheels, one of the earliest forms of energy storage, could play a significant role in the transformation of the electri-cal power system into one that is fully sustainable yet low cost.

Get a quote

Flywheel Energy Storage

Key uses for Flywheel Energy Storage Fast Response Time - Flywheels can store and release energy almost instantly, making them ideal for applications that require quick energy bursts or

Get a quote

Grid-Scale Flywheel Energy Storage Plant

The plant will provide a response time of less than four seconds to frequency changes. With availability of more than 97%, as demonstrated in earlier small-scale pilots, this technology

Get a quote

Kinetic Energy Storage (Flywheels)

For releasing the energy, the electrical machine (acting as a generator) applies a negative torque –T to the flywheel, braking it at a rate – (T/J) and pumping the energy back to the grid or the

Get a quote

Flywheel Energy Storage: Alternative to Battery Storage

Flywheels offer an alternative to batteries for energy storage. Discover the benefits of flywheel energy storage for time-shifting power.

Get a quote

Technology: Flywheel Energy Storage

FESS is used for short-time storage and typically offered with a charging/discharging duration between 20 seconds and 20 minutes. However, one 4-hour duration system is available on the

Get a quote

What is the self-discharge rate of flywheel energy

The self-discharge rate of flywheel energy storage systems typically ranges between 1% to 5% per hour. This low rate is significant when

Get a quote

How flywheel energy storage works

How Flywheel Energy Storage Systems Work. Flywheel energy storage systems (FESS) employ kinetic energy stored in a rotating mass with very low frictional losses. Electric energy input

Get a quote

Flywheel energy storage discharge time is short

The response time of the flywheel energy storage system can reach the order of ten milliseconds, and the charging and discharging efficiency of the flywheel energy storage

Get a quote

What Determines Flywheel Energy Storage Discharge Time? The

The secret often lies in flywheel energy storage discharge time – the unsung hero of instant power delivery. Unlike batteries that need coffee breaks to recharge, flywheels spin

Get a quote

Flywheel standby discharge rate in 24 h.

Flywheel standby discharge rate in 24 h. Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel energy storage system...

Get a quote

Flywheel energy storage

Amber Kinetics, Inc. has an agreement with Pacific Gas and Electric (PG&E) for a 20 MW / 80 MWh flywheel energy storage facility located in Fresno, CA with a four-hour discharge duration.

Get a quote

Overview of Flywheel Systems for Renewable Energy

Energy can be stored through various forms, such as ultra-capacitors, electrochemical batteries, kinetic flywheels, hydro-electric power or compressed air. Their comparison in terms of specific

Get a quote

Flywheel Energy Storage System: What Is It and How Does It

Rapid Charge/Discharge: Flywheels can charge and discharge electricity much faster than traditional batteries, making them ideal for balancing power grids or managing short-term

Get a quote

Flywheel standby discharge rate in 24 h.

Flywheel standby discharge rate in 24 h. Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel

Get a quote

A Review of Flywheel Energy Storage System Technologies

The operation of the electricity network has grown more complex due to the increased adoption of renewable energy resources, such as wind and solar power. Using

Get a quote

Flywheel energy storage discharge time is short

The attractive attributes of a flywheel are quick response, high efficiency, longer lifetime, high charging and discharging capacity, high cycle life, high power and energy density, and lower

Get a quote

Analysis of Standby Losses and Charging Cycles in

Aerodynamic drag and bearing friction are the main sources of standby losses in the flywheel rotor part of a flywheel energy storage system

Get a quote

6 FAQs about [Flywheel energy storage discharge time]

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

What is a flywheel energy storage system?

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher tensile strength than steel and can store much more energy for the same mass. To reduce friction, magnetic bearings are sometimes used instead of mechanical bearings.

How does a flywheel work?

Here’s a breakdown of the process: Energy Absorption: When there’s surplus electricity, such as when the grid is overproducing energy, the system uses that excess power to accelerate the flywheel. This energy is stored as kinetic energy, much like how the figure skater speeds up their spin by pulling in their arms.

How long does a fess flywheel last?

However, only a small percentage of the energy stored in them can be accessed, given the flywheel is synchronous (Ref. 2). FESS is used for short-time storage and typically offered with a charging/discharging duration between 20 seconds and 20 minutes. However, one 4-hour duration system is available on the market.

How does a flywheel retain energy?

Energy Storage: The flywheel continues to spin at high speed, maintaining energy as long as friction and resistance are minimized. The longer it spins, the more energy it holds, similar to how the skater retains rotational energy as they keep spinning.

How long do flywheels last?

Long Lifespan: With no chemical reactions involved, flywheels can last for tens of thousands of cycles, significantly outperforming batteries in terms of longevity. High Efficiency: Flywheel systems are highly efficient at storing and releasing energy, with minimal energy loss over time.

Guess what you want to know

-

Flywheel energy storage discharge efficiency

Flywheel energy storage discharge efficiency

-

Charge and discharge time of energy storage battery

Charge and discharge time of energy storage battery

-

Flywheel energy storage deep discharge price

Flywheel energy storage deep discharge price

-

Flywheel energy storage system fast discharge

Flywheel energy storage system fast discharge

-

Andor Flywheel Energy Storage

Andor Flywheel Energy Storage

-

Enterprises producing flywheel energy storage in Liberia

Enterprises producing flywheel energy storage in Liberia

-

Effective range of Malta flywheel energy storage

Effective range of Malta flywheel energy storage

-

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

Austria s Flywheel Energy Storage Photovoltaic Power Generation Ranking

-

Grid-scale flywheel energy storage

Grid-scale flywheel energy storage

-

Flywheel energy storage peak shaving and valley filling system

Flywheel energy storage peak shaving and valley filling system

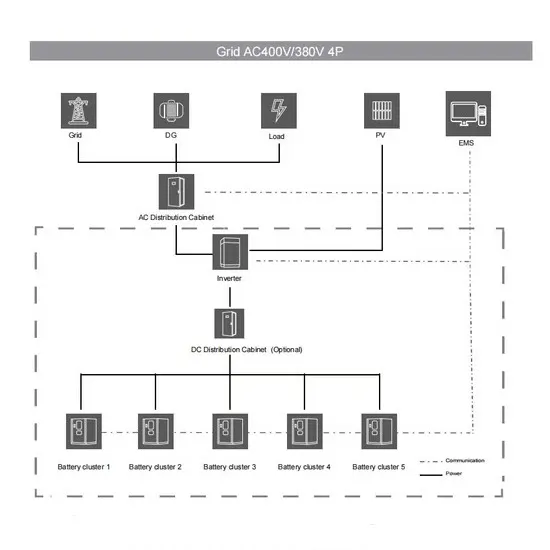

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.