Water Cooling System for Flywheel Energy Storage 2025-2033

The global market for water cooling systems in flywheel energy storage is experiencing robust growth, driven by the increasing adoption of flywheel energy storage

Get a quote

A review of flywheel energy storage systems: state of the art

Energy storage systems (ESS) play an essential role in providing continu-ous and high-quality power. ESSs store intermittent renewable energy to create reliable micro-grids

Get a quote

Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components, characteristics, applications,

Get a quote

A review of flywheel energy storage systems: state of the art

ESSs store intermittent renewable energy to create reli-able micro-grids that run continuously and e ciently distribute electricity by balancing the supply and the load [1]. The existing energy

Get a quote

Peer Review Oct 2005

Objective: • build and deliver flywheel energy storage systems utilizing high temperature superconducting (HTS) bearings tailored for uninterruptible power systems and off-grid

Get a quote

Flywheel energy storage rotor cooling system

The invention discloses a flywheel energy storage rotor cooling system which mainly comprises a vacuum shell, an electromagnetic bearing, a rotor, a flywheel, a motor, a condensation

Get a quote

Flywheel energy storage

OverviewMain componentsPhysical characteristicsApplicationsComparison to electric batteriesSee alsoFurther readingExternal links

A typical system consists of a flywheel supported by rolling-element bearing connected to a motor–generator. The flywheel and sometimes motor–generator may be enclosed in a vacuum chamber to reduce friction and energy loss. First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors

Get a quote

Flywheel Energy Storage Systems | Electricity

This flywheel, when paired to a motor/generator unit, behaves like a battery and energy can be stored for hours and dispatched on demand. The system

Get a quote

Flywheel Systems for Utility Scale Energy Storage

The kinetic energy storage system based on advanced flywheel technology from Amber Kinetics maintains full storage capacity throughout the product lifecycle, has no emissions, operates in

Get a quote

The most complete analysis of flywheel energy storage for new energy

This article introduces the new technology of flywheel energy storage, and expounds its definition, technology, characteristics and other aspects.

Get a quote

Case study on flywheel energy storage systems: LPTN-based

The flywheel energy storage system employs a chiller to provide cooling for the motor and converter. The chiller water tank has a capacity of 50 L, with a maximum cooling

Get a quote

US20020073941A1

A flywheel energy storage system for maintaining fan speed of a cooling fan on an internal combustion engine. The flywheel energy storage system allows a fan to rotate independent of

Get a quote

Flywheel Energy Storage System: What Is It and How Does It

This article will explain the flywheel energy storage system (FESS). You can learn about its working principle, advantages and disadvantages And the comparison with BESS in the article

Get a quote

Flywheel Energy Storage System: What Is It and How

This article will explain the flywheel energy storage system (FESS). You can learn about its working principle, advantages and disadvantages And the

Get a quote

Cooling System for a 200kW Flywheel Energy Storage Power

Abstract: The design of the cooling system for a 200kW flywheel energy storage power vehicle, emphasizing the integration of shelter air conditioning and axial flow fans for efficient heat

Get a quote

Flywheel energy storage systems: A critical review on

In this article, an overview of the FESS has been discussed concerning its background theory, structure with its associated components,

Get a quote

Flywheel Systems for Utility Scale Energy Storage

Flywheel Systems for Utility Scale Energy Storage is the final report for the Flywheel Energy Storage System project (contract number EPC-15-016) conducted by Amber Kinetics, Inc.

Get a quote

New Energy Storage System Links Flywheels And Batteries

1 day ago· The Utah-based startup is launching a hybrid system that connects the mechanical energy storage of advanced flywheel technology to the familiar chemistry of lithium-ion batteries.

Get a quote

Technology: Flywheel Energy Storage

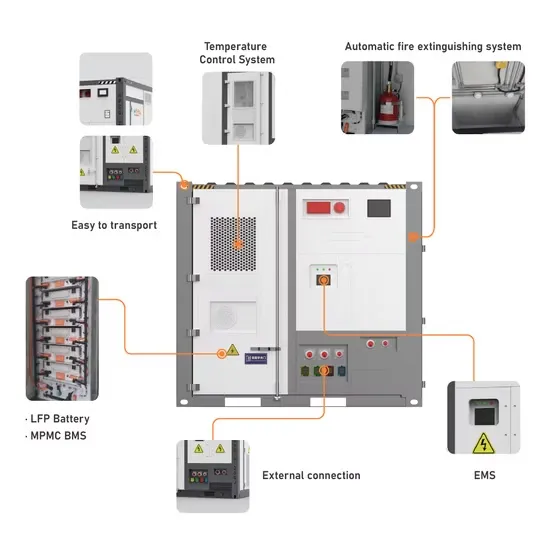

The system consists of a 40-foot container with 28 flywheel storage units, electronics enclosure, 750 V DC-circuitry, cooling, and a vacuum system. Costs for grid inverter, energy

Get a quote

Flywheel Storage: How It Works and Why Thermal Batteries Are

Flywheel storage is a technology used to store thermal energy and gradually distribute it in heating and cooling systems. Among its main applications is the chilled water

Get a quote

A Comprehensive Analysis of the Loss Mechanism

This paper presents a comprehensive analytical framework for investigating loss mechanisms and thermal behavior in high-speed magnetic

Get a quote

Jet impingement cooling in rotating flywheel energy storage systems

Building upon prior research and operational characteristics of flywheel energy storage systems (FESS), this study investigates jet impingement cooling mechanisms in

Get a quote

Development of Superconducting Magnetic Bearing for 300 kW Flywheel

The world''s largest-class flywheel energy storage system (FESS), with a 300 kW power, was established at Mt. Komekura in Yamanashi prefecture in 2015. The FESS,

Get a quote

Flywheel energy storage

First-generation flywheel energy-storage systems use a large steel flywheel rotating on mechanical bearings. Newer systems use carbon-fiber composite rotors that have a higher

Get a quote

Control technology and development status of flywheel

Introducing the basic structure of the flywheel energy storage system in the above three applications. Typical charge-discharge control strategies are given for the three sensor-less

Get a quote

Flywheel energy storage

As one of the interesting yet promising technologies under the category of mechanical energy storage systems, this chapter presents a comprehensive introduction and

Get a quote

Flywheel Energy Storage Systems | Electricity Storage Units

This flywheel, when paired to a motor/generator unit, behaves like a battery and energy can be stored for hours and dispatched on demand. The system service life is 20 years, without limits

Get a quote

6 FAQs about [Flywheel energy storage cooling system]

What is a flywheel energy storage system?

Fig. 1 has been produced to illustrate the flywheel energy storage system, including its sub-components and the related technologies. A FESS consists of several key components: (1) A rotor/flywheel for storing the kinetic energy. (2) A bearing system to support the ro-tor/flywheel.

What is flywheel technology?

Flywheel technology is a method of energy storage that uses the principles of rotational kinetic energy. A flywheel is a mechanical device that stores energy by spinning a rotor at very high speeds.

Can flywheel energy storage be commercially viable?

This project explored flywheel energy storage R&D to reach commercial viability for utility scale energy storage. This required advancing the design, manufacturing capability, system cost, storage capacity, efficiency, reliability, safety, and system level operation of flywheel energy storage technology.

What is the difference between a flywheel and a battery storage system?

Flywheel Systems are more suited for applications that require rapid energy bursts, such as power grid stabilization, frequency regulation, and backup power for critical infrastructure. Battery Storage is typically a better choice for long-term energy storage, such as for renewable energy systems (solar or wind) or home energy storage.

What is flywheel/kinetic energy storage system (fess)?

and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the recent

What are the advantages of flywheel technology?

One of the advantages of flywheel technology is the environmental tolerance; chemical batteries perform poorly outside of a limited temperature range which often necessitates axillary heating and cooling systems that reduce system power conversion efficiency.

Guess what you want to know

-

Flywheel energy storage cooling system

Flywheel energy storage cooling system

-

Togo liquid cooling energy storage form

Togo liquid cooling energy storage form

-

Industrial and commercial energy storage liquid cooling configuration

Industrial and commercial energy storage liquid cooling configuration

-

Huawei liquid cooling energy storage system support

Huawei liquid cooling energy storage system support

-

Latest Liquid Cooling Energy Storage

Latest Liquid Cooling Energy Storage

-

Greenhouse solar energy storage cooling and heating system

Greenhouse solar energy storage cooling and heating system

-

Saudi Arabia Urban Liquid Cooling Energy Storage Container Selling Price

Saudi Arabia Urban Liquid Cooling Energy Storage Container Selling Price

-

What is Industrial and Commercial Energy Storage Liquid Cooling

What is Industrial and Commercial Energy Storage Liquid Cooling

-

Malta Energy Storage Liquid Cooling System

Malta Energy Storage Liquid Cooling System

-

Liquid Cooling Energy Storage Cabinet Analysis

Liquid Cooling Energy Storage Cabinet Analysis

Industrial & Commercial Energy Storage Market Growth

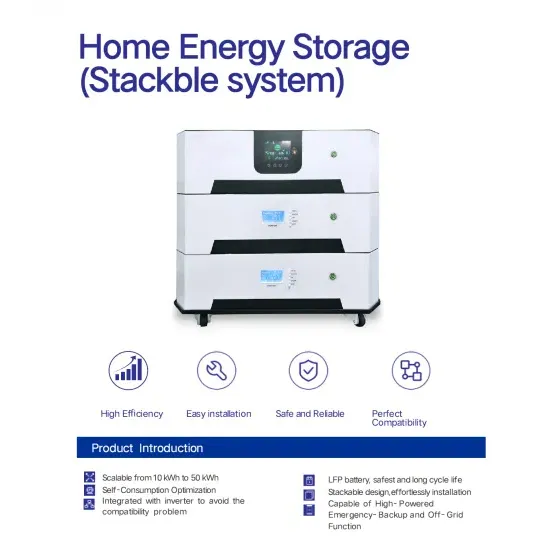

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.