Understanding Inverter Input and Output: What is the Relationship

The level of input stability will greatly affect the quality of the output from voltage to frequency, so many inverters today are equipped with input optimization technology and also output stability.

Get a quote

Automatic Inverter Output Voltage Correction Circuit

The simple inverter automatic load voltage correction circuit presented below could be effectively used for the proposed application and for

Get a quote

Voltage Control Using Inverter Reactive Power Control

4. Constant reactive power mode In this mode, the inverter either injects or absorbs a constant amount of reactive power, independent of real

Get a quote

4. Configuration

Do not use the "Dynamic cut off" feature in an installation that also has other loads connected to the same battery. In these systems the battery voltage might drop because of other loads

Get a quote

How Inverters Work

How do Inverters work? In this article we''ll be learning how inverters work, starting from the very basics. We''ll cover Pulse Width Modulation, PWM and variable frequency drives.

Get a quote

How to Read Solar Inverter Specifications

Maximum Power Point Tracking or MPPT refers to the optimal voltage level at which the inverter can extract the most power from the solar panels. So, for efficient power

Get a quote

How to Adjust Voltage Regulator: A Comprehensive

6. Fine-Tuning the Voltage Regulator If the output voltage is not within the desired range, further fine-tuning may be necessary. Some voltage regulators have

Get a quote

Voltage Control Methods of Inverter – PWM Technique

The ability of an inverter to accurately convert DC to AC, operate within specified voltage and current limits, and incorporate safety and control features such as

Get a quote

Understanding Inverter Input and Output: What is the

The level of input stability will greatly affect the quality of the output from voltage to frequency, so many inverters today are equipped with input optimization

Get a quote

Changing inverter voltage output?

Modern switching regulated power supplies will still pull about the same power by pulling less current at the higher voltage, but an old style linear regulator will have to drop the

Get a quote

Automatic Inverter Output Voltage Correction Circuit

The simple inverter automatic load voltage correction circuit presented below could be effectively used for the proposed application and for regulating the output of an inverter

Get a quote

CSM_Inverter_TG_E_1_2

With this method, the inverter monitors the output voltage, the output current, and the encoder feedback from the motor. The encoder feedback is used to adjust the output waveform to

Get a quote

How Does an Inverter Generator Work?

Precise Control: The ability to precisely control output voltage and frequency enables inverters to power a wide range of devices, including sensitive electronics.

Get a quote

Troubleshooting 32 Problems and Solutions of Solar

Solar Inverter Problems and Solutions: Restart the device, check connections, and contact the manufacturer for an investigation if needed.

Get a quote

Avoiding common issues when tuning an inverter to

A little knowledge of some key factors and potential issues can help smooth the process of tuning an inverter to an electric motor. Patrick

Get a quote

A review on high-resolution CMOS delay lines:

It is designed using N inverters connected in series where two adjacent inverters form a delay element. Thus, its delay step is equal to the

Get a quote

The Impact of Frequency Mixing Adjustments in Inverters

Improving Power Quality Another critical effect of frequency adjustment in inverters is its role in improving power quality. By fine-tuning the

Get a quote

Understanding inverter voltage

In most cases, the output inverter voltage is factory-set to match the standard voltage requirements of the region. Users typically do not need to adjust the output voltage

Get a quote

Voltage Control Methods of Inverter – PWM Technique

The output voltage of an inverter can be adjusted by employing the control technique within the inverter itself. This control technique can be accomplished by the

Get a quote

Synchronization of the solar inverter with the grid

By fine-tuning the synchronization of solar inverters with the grid, operators can make sure that solar energy systems are operating at peak

Get a quote

CSM_Inverter_TG_E_1_1

Although there is no feedback signal from a sensor, the current and voltage output from the inverter to the motor are used to correct the output waveform. This enables finer speed

Get a quote

Avoiding common issues when tuning an inverter to an electric

A little knowledge of some key factors and potential issues can help smooth the process of tuning an inverter to an electric motor. Patrick Berkner, Systems Application Engineer

Get a quote

Inverter Specifications and Data Sheet

The ability of an inverter to accurately convert DC to AC, operate within specified voltage and current limits, and incorporate safety and control features such as MPPT, transfer switches,

Get a quote

How to Optimize Your Inverter Settings for Solar Panels

The inverter''s AC output voltage should match the voltage supplied by your utility grid. Proper voltage alignment ensures smooth power transfer and prevents

Get a quote

How to Optimize Your Inverter Settings for Solar Panels

The inverter''s AC output voltage should match the voltage supplied by your utility grid. Proper voltage alignment ensures smooth power transfer and prevents voltage fluctuations that can

Get a quote

6 FAQs about [Does the inverter output have fine-tuning voltage ]

What do you need to know about input power inverters?

Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V.

How to control AC voltage in an inverter?

Basically, there are three techniques by which the voltage can be controlled in an inverter. They are, Internal control of Inverter. In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage.

What are the characteristics of an output inverter?

The output produced by the inverter is an alternating current (AC) that is usually used to power various kinds of electronic devices needed in everyday life such as lights, fans, televisions, and so on. Here are some characteristics of the output inverter. Output Voltage: must match the connected device to prevent damage.

What makes a good inverter?

The ability of an inverter to accurately convert DC to AC, operate within specified voltage and current limits, and incorporate safety and control features such as MPPT, transfer switches, and ground fault protection ensures optimal energy performance and system longevity.

How a voltage control inverter helps in achieving voltage variation?

In the case of variable speed drives, inverters with voltage control help in achieving voltage variation. Voltage control of inverters is employed in order to compensate for changes in input dc voltage.

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

Guess what you want to know

-

Inverter output voltage returns to zero

Inverter output voltage returns to zero

-

Is the inverter output voltage 233v normal

Is the inverter output voltage 233v normal

-

Inverter voltage fine-tuning

Inverter voltage fine-tuning

-

Inverter output voltage is slow

Inverter output voltage is slow

-

Inverter working output voltage is high

Inverter working output voltage is high

-

New energy inverter output voltage

New energy inverter output voltage

-

Pulse inverter output voltage

Pulse inverter output voltage

-

What is the inverter s continuous output voltage

What is the inverter s continuous output voltage

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

The inverter has a high voltage output

The inverter has a high voltage output

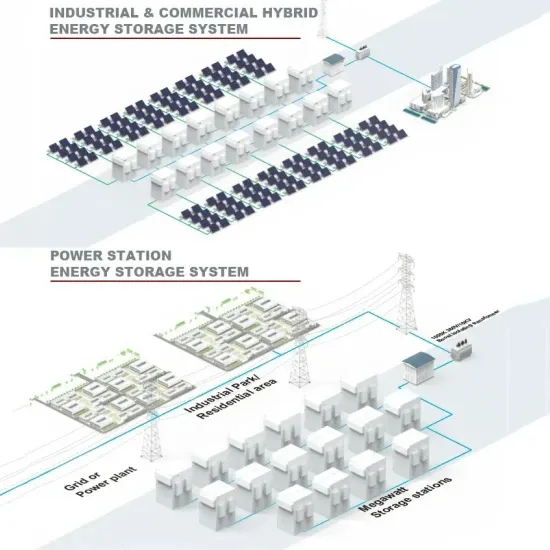

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.