What Happens If You Overload Your Inverter? Real Dangers and

First, we''ll talk about what actually happens when your inverter gets overloaded. Then, we''ll go over the dangers you need to know about. And most importantly, we''ll show you

Get a quote

CMOS Inverter: Definition, Working Principle, and

Explore the world of CMOS inverters with our comprehensive guide. Learn about their definition, working principle, key characteristics,

Get a quote

On sunny days, Inverter switches off when DC voltage gets too

At other times of the day, when the battery reaches 100%, the DC voltage is not as high and the inverter does not switch off. Amps do not rise above 10.3A on each string, at

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

What the heck? I am afraid it''s my inverter that has been damaging my appliance. I open up this fan and got it running again, but it seem it doesn''t run as fast as it use to run. My 6000BTU

Get a quote

Inverter too high output voltage than normal, problem?

It has a detection voltage range of 180V to 260V and turns on when the electricity voltage is higher or lower when it is set to UPS Mode. Its detection mode is higher (they do not

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always

Get a quote

Understanding Inverter Voltage: Definition, Functions,

The high-voltage inverter itself has a high input voltage power of more than 600V. While the output voltage reaches 3.3kV, 6.6kV, or can even

Get a quote

DC-to-AC Converters (Inverters): Design, Working & Applications

2. Inverter – this is the main power circuit. It is here that the d.c. is converted into a multilevel PWM waveform. 3.Output Filter – the output filter removes the high-frequency

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage. This is caused by a high intermediate circuit DC voltage. This

Get a quote

On sunny days, Inverter switches off when DC voltage gets too high

At other times of the day, when the battery reaches 100%, the DC voltage is not as high and the inverter does not switch off. Amps do not rise above 10.3A on each string, at

Get a quote

Inverter Basics: Classification and Applications

Inverter Basics: Resonant Inverters This is the class of inverters in which output voltage or current is passed though zero to minimize switching

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always working efficiently!

Get a quote

How Does Input Voltage Affect a Grid-Tie Inverter?

In the photovoltaic grid-tie inverter, there are many input voltage technical parameters: Maximum DC input voltage, MPPT operating voltage

Get a quote

Voltage Inverter : Circuit, Working and Its Applications

Generally, many people have confused on voltage inverter and converter, and their working principles. An inverter is an electrical device, which converts DC power to AC power

Get a quote

What Is An Inverter? | Definition, Types, Uses, How It Works

The process begins with the DC voltage being supplied to the inverter''s circuit. The inverter uses an oscillator to switch the current on and off at a high frequency. This creates a

Get a quote

High-Frequency Inverter: How They Work and Why

The working principle of a high-frequency inverter is the same as that of a regular inverter that converts DC to AC but at a high frequency. It involves a series of

Get a quote

Understanding inverter voltage

An abnormally high inverter output voltage may indicate a malfunction in the voltage regulation circuit. Addressing this issue promptly is crucial to prevent potential damage

Get a quote

What is CMOS Inverter : Working & Its Applications

CMOS Inverter Operation & Working The working of CMOS inverter is the same as other types of FETs except depends on an oxygen layer to divide electrons

Get a quote

Troubleshooting Inverter Problems: A Step-by-Step Guide

Check the Battery: Ensure that the battery is fully charged. If the battery voltage is too low, the inverter may not turn on. Use a multimeter to measure the voltage. If it''s below the

Get a quote

Inveter AC output voltage too high?

What the heck? I am afraid it''s my inverter that has been damaging my appliance. I open up this fan and got it running again, but it seem it doesn''t run as fast as it use to run. My 6000BTU

Get a quote

6 FAQs about [Inverter working output voltage is high]

What causes a DC inverter to overvoltage?

This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage. There are other causes of DC overvoltage, however. POSSIBLE FIXES: Turn the overvoltage controller is on. Check supply voltage for constant or transient high voltage. Increase deceleration time.

What are the most common faults on inverters?

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage Overvoltage This is caused by a high intermediate circuit DC voltage. This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage.

What causes low output inverter voltage?

Low output inverter voltage can stem from issues such as a weak battery, loose connections, or internal faults. Thoroughly troubleshooting these aspects can help identify and rectify the cause of low output inverter voltage. Why is inverter output voltage so high?

What if the frequency inverter voltage is too high?

When the system voltage is too high, the frequency inverter may not be able to stop at a numerical point in order to avoid triggering the DC bus over-voltage protection for its own protection. In such cases, it is recommended to connect the transformer taps to 105%.

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

What if my inverter is over-current?

Motor over-current. The inverter’s output current is 1.2 times greater than the rated motor current and continues for over 2 minutes. Please check if the parameter setting for the motor’s rated current is correct. Also, check if the motor or load machinery is blocked and if the power supply voltage is too low.

Guess what you want to know

-

The inverter has a high voltage output

The inverter has a high voltage output

-

Is the inverter voltage output high or low

Is the inverter voltage output high or low

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Monaco high voltage inverter

Monaco high voltage inverter

-

Use inverter when voltage is high

Use inverter when voltage is high

-

High voltage power station output voltage

High voltage power station output voltage

-

The voltage used by the inverter is too high

The voltage used by the inverter is too high

-

Single-phase high and low voltage inverter

Single-phase high and low voltage inverter

-

Pulse inverter output voltage

Pulse inverter output voltage

-

Inverter high voltage side and low voltage side

Inverter high voltage side and low voltage side

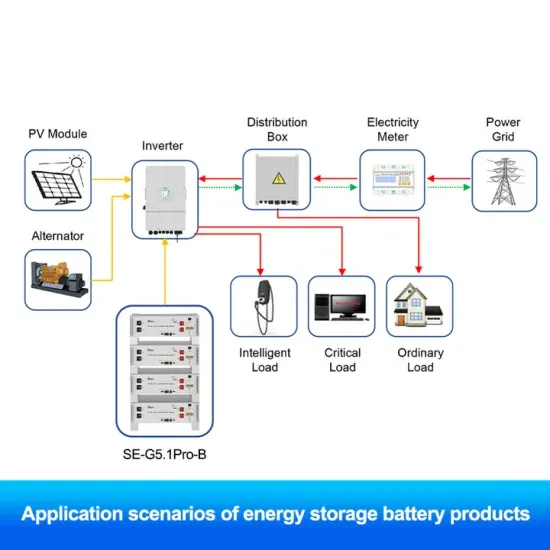

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

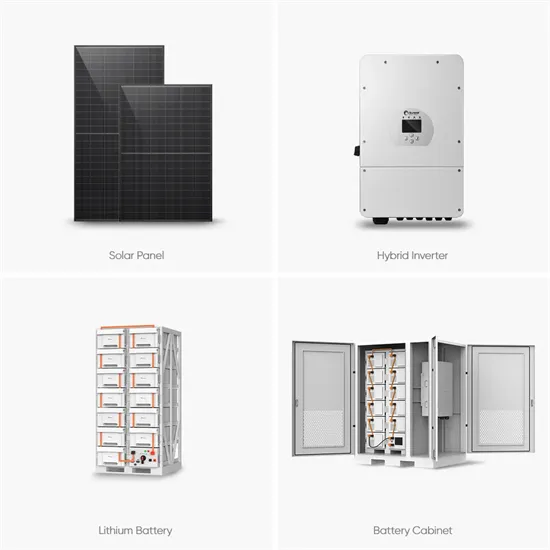

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.