What Happens If You Overload Your Inverter? Real Dangers and

This in-depth guide breaks down the symptoms, dangers, and long-term effects of pushing your inverter too hard. Learn how to calculate load, prevent overload, and fix issues if

Get a quote

Growatt inverter error codes + troubleshooting tips

Growatt inverters are widely used in solar energy systems in order to help convert the direct current (DC) from solar panels into the alternating

Get a quote

Inverter too high output voltage than normal, problem?

It has a detection voltage range of 180V to 260V and turns on when the electricity voltage is higher or lower when it is set to UPS Mode. Its detection mode is higher (they do not

Get a quote

10 common inverter failure and the solutions – TYCORUN

This article will give you an overall guide on the reasons of 10 common inverter failure and the solutions step by step to solve these problems.

Get a quote

How to Troubleshoot AC Overvoltage of Solar Inverter?

The voltage becomes normal after changing new cable connection point and switch. Then, the solar inverter is back to normal operation. How to inspect the AC voltage failures?

Get a quote

On sunny days, Inverter switches off when DC voltage gets too high

Too many volts suggests to me that some component might overheat and ignite, or its electronics burn out, or that the inverter fails completely, as the inverter would not switch

Get a quote

Input Voltage is Too High... what to do?

I have all the inverter settings at default values, Grid Upper Voltage Limit 132 VAC Grid Upper Voltage Limit 132 2021-01-03 14-31-58.png I suppose that is the safest however

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage. This is caused by a high intermediate circuit DC voltage. This

Get a quote

Overvoltage is impacting your Solar Systems

Overvoltage is one of the most common issues that impact your panels'' performance, it happens when the grid voltage exceeds 258 volts and it when

Get a quote

What causes inverter overvoltage errors? – Solar Power Store

Check your inverter''s maximum DC input voltage and ensure your solar array is designed within that limit—even during cold weather conditions. Use design tools or consult a professional to

Get a quote

Generator Voltage Too High (Problems & Quick Solutions)

Generator voltage that is too high will harm the sensitive components of electronic devices. The excess heat generated by the high voltage can destroy the circuit boards in your appliances.

Get a quote

Problem with inverter? High and low voltage error messages

At night (eg 4am when dark) the inverter was beeping with an error message: [03]''battery voltage is too high''. The first time the error message appeared the battery voltage

Get a quote

FAQ of Solar Inverters

3. Use the multimeter to check if the grid connection is correct, and check if phase voltage and line voltage is too low 4. Check if the inverter''s safety code be set correctly and Grid under

Get a quote

[SolarEdge 2xE] AC voltage too high, grid over-voltage? : r/solar

Most string inverters have a normal voltage operating range, but that range can usually be extended by 10% or so. Usually if they need the upper voltage limit to be raised, you''ll have to

Get a quote

On sunny days, Inverter switches off when DC voltage gets too

Too many volts suggests to me that some component might overheat and ignite, or its electronics burn out, or that the inverter fails completely, as the inverter would not switch

Get a quote

How to solve the AC inverter overvoltage problem?

In addition, the cable used by the inverter to the grid point is too long, too thin, entangled or the material is not in compliance, which will lead to

Get a quote

Inveter AC output voltage too high?

When I first got it, the output voltage was 129-130, so I ask the manufacture and they can I can adjust a POD inside and that has reduced it down to 125v (lowest it can go).

Get a quote

Troubleshooting Guide for Growatt Off Grid High Frequency

Inverter System introduction: SPF 2000-5000TL HVM Fault condition and Troubleshooting Part I. Fault 1 03fault 03fault means battery voltage is too high.

Get a quote

[SOLVED] P0C79 Code: Drive Motor ''a'' Inverter Voltage Too High

The P0C79 fault code refers to the Drive Motor ''A'' Inverter Voltage being too high. This code is set by the Engine Control Module (ECM) when the Drive Motor ''A'' Inverter does not meet the

Get a quote

[SolarEdge 2xE] AC voltage too high, grid over-voltage? : r/solar

Most string inverters have a normal voltage operating range, but that range can usually be extended by 10% or so. Usually if they need the upper voltage limit to be raised,

Get a quote

what does AC Voltage High mean and what should one do?

The IEEE 1547 standard requires that grid-tied or utility-interactive inverters cease power production if voltage measured at the inverter terminal exceeds +10% or -12% of nominal.

Get a quote

6 FAQs about [The voltage used by the inverter is too high]

What causes a DC inverter to overvoltage?

This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage. There are other causes of DC overvoltage, however. POSSIBLE FIXES: Turn the overvoltage controller is on. Check supply voltage for constant or transient high voltage. Increase deceleration time.

What are the most common faults on inverters?

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage Overvoltage This is caused by a high intermediate circuit DC voltage. This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage.

Why is the AC side voltage of the inverter too high?

Reasons why the AC side voltage of the inverter is too high: ① The cable between the inverter and the grid connection point is too thin, too long, entangled, or the cable material is unqualified, causing the voltage on the AC side of the inverter to rise (ΔU increases).

Why is my inverter screen not working?

Reason 3: The DC input voltage is too low. When the string output voltage is lower than the minimum input voltage of the inverter, there is no display on the inverter screen. To make sure, you can use a multimeter to measure the output voltage of the photovoltaic string to see whether the voltage reaches the minimum input voltage of the inverter.

What causes a grid overvoltage inverter failure?

② Due to the local grid connection conditions of the photovoltaic power station, multiple single-phase inverters are connected to the same live line, and the grid's accommodation capacity is insufficient, causing the grid voltage to rise too high, and the inverter reports a grid overvoltage inverter failure.

What is a good AC voltage for an inverter?

The upper limit for inverter ac voltage is typically 264v, so raised to the limit it would keep you operational with a couple volts wiggle room. That said at 130/260v you’re going to be putting a strain on electronic circuits in the house. Utility really shouldn’t be running that high for any amount of time.

Guess what you want to know

-

Input voltage high inverter

Input voltage high inverter

-

Imported high voltage inverter wholesale

Imported high voltage inverter wholesale

-

Inverter voltage high and low

Inverter voltage high and low

-

High voltage inverter 500w

High voltage inverter 500w

-

Inverter high voltage protection setting

Inverter high voltage protection setting

-

The impact of high voltage on inverter

The impact of high voltage on inverter

-

Amorphous machine inverter high voltage

Amorphous machine inverter high voltage

-

Use inverter when voltage is high

Use inverter when voltage is high

-

How much power does a high voltage inverter have

How much power does a high voltage inverter have

-

High voltage battery connected to inverter

High voltage battery connected to inverter

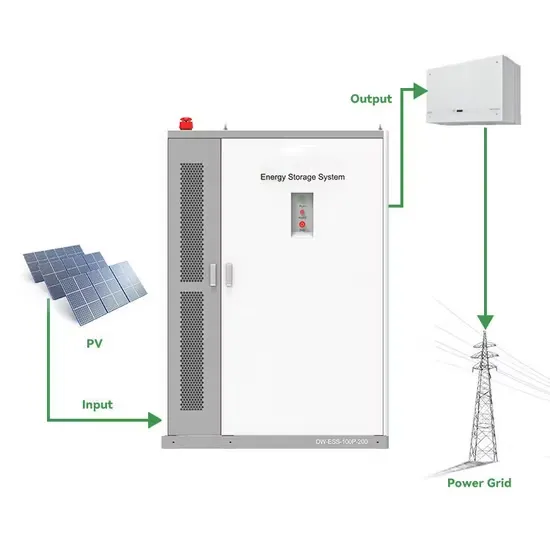

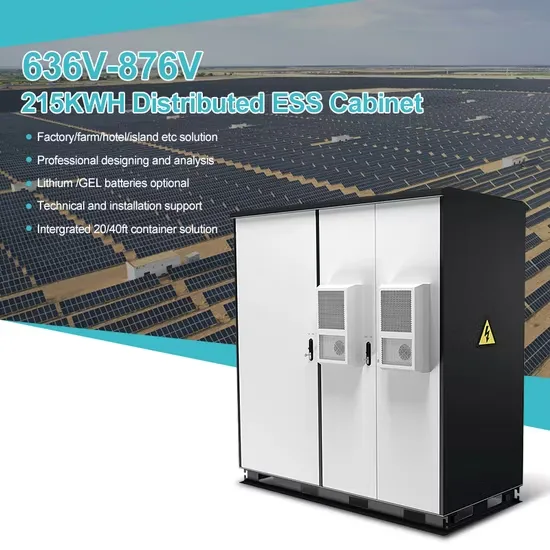

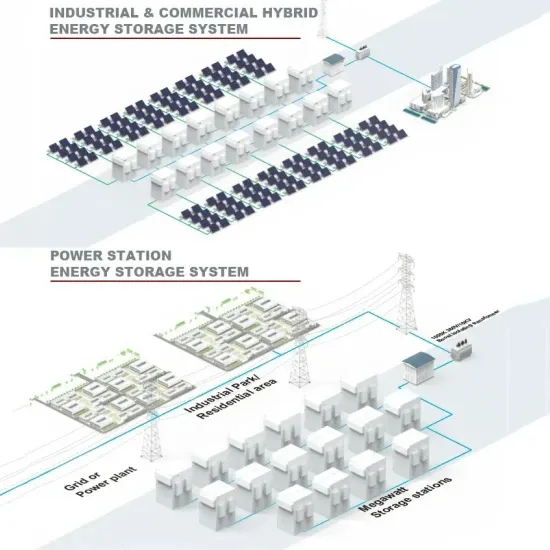

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

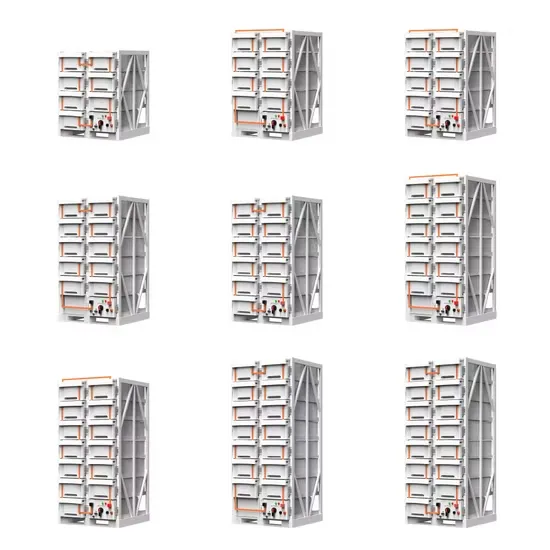

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.