High Voltage Inverter: What They Are, How They

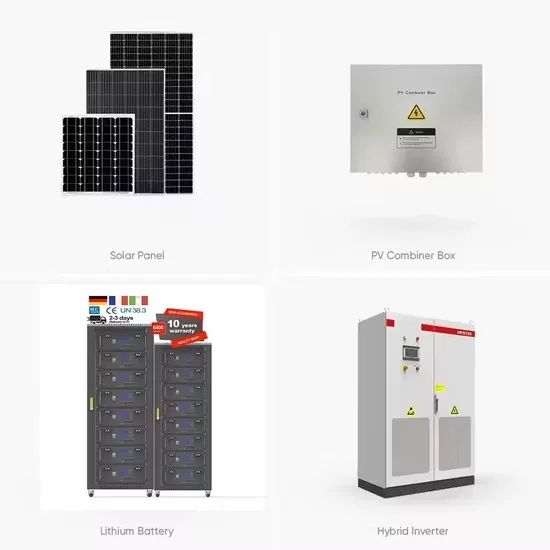

What is a High Voltage Inverter? A high voltage inverter is a device that converts the direct current (DC) electricity from solar panels or batteries into high

Get a quote

Inverter AC Input Voltage is too High

Inverter on port 1 has detected Low Battery Voltage. Measured Battery Voltage 61.2 VDC. 07/12/2020 09:19 Inverter on port 1, Low Battery Voltage warning has cleared. Measured

Get a quote

High Voltage Inverter: What They Are, How They Work, and

What is a High Voltage Inverter? A high voltage inverter is a device that converts the direct current (DC) electricity from solar panels or batteries into high voltage alternating current (AC)

Get a quote

High Voltage Inverter Design

VF high-voltage sense input voltage is fed back to the control system. Figure 4/High voltage inverter main circuit SCM control system Figure 5 shows the complete block diagram of the

Get a quote

When choosing an inverter, what voltage ratings

Typically, residential inverters have a maximum input voltage between 500V and 1000V. Choosing one with a higher rating ensures greater flexibility and better

Get a quote

What You Need To Know About a High Volt Inverter

A high-voltage inverter is designed to convert DC power into AC at a higher voltage than a standard inverter. It can accept inputs from high-voltage power sources and then convert them

Get a quote

High Voltage Inverters

High Voltage Inverters Hi, Does victron plan on making any high voltage inverters? Like 135 - 600V dc input? Seeing a few new batteries in this range, like FreedomWon Lite HV

Get a quote

WHY DO INVERTERS LIMIT PV INPUT VOLTAGE?

If the input voltage is too high, it can put undue stress on the inverter, leading to a potential hazard. By limiting the PV input voltage, our

Get a quote

CSM_Inverter_TG_E_1_1

An inverter uses this feature to freely control the speed and torque of a motor. This type of control, in which the frequency and voltage are freely set, is called pulse width modulation, or PWM.

Get a quote

The Technology Behind High Input Voltage Inverters

High input voltage inverters are designed to handle voltages higher than their conventional counterparts. They typically have a wide input voltage range, making them

Get a quote

difference between PV input and MPPT range

this is my solar inverter datasheet i don''t get the difference between the MPPT and The PV input voltage my each pv in series should equal to 500v? or to 425?

Get a quote

How Does Input Voltage Affect a Grid-Tie Inverter?

In order to prevent the inverter from being started repeatedly, the start-up voltage of the inverter is higher than the minimum operating voltage. After the grid tie inverter is

Get a quote

What is the cause of the overvoltage of the inverter? How to

The overvoltage of the power supply means that the DC bus voltage exceeds the rated value because the power supply voltage is too high. Most of the inverters now have an

Get a quote

Interpreting inverter datasheet and main parameters | AE 868

PV designers should choose the PV array maximum voltage in order not to exceed the maximum input voltage of the inverter. At the same time, PV array voltage should operate within the

Get a quote

High Input Voltage Inverters | Products & Suppliers | GlobalSpec

ABSOPULSE Electronics'' CSH 500-F6 series of heavy-duty, high input voltage DC-AC sine wave inverters deliver 500VA pure sinewave output voltage. They convert 600Vdc industrial input

Get a quote

When choosing an inverter, what voltage ratings should you pay

Typically, residential inverters have a maximum input voltage between 500V and 1000V. Choosing one with a higher rating ensures greater flexibility and better performance in different

Get a quote

High voltage DC-AC sine wave inverters accept wide input

The high input voltage DC-AC sine wave inverters are designed for industrial applications that require clean sine wave AC-output voltage. They are suitable for operation in industrial

Get a quote

How Does Input Voltage Affect a Grid-Tie Inverter?

In order to prevent the inverter from being started repeatedly, the start-up voltage of the inverter is higher than the minimum operating voltage.

Get a quote

WHY DO INVERTERS LIMIT PV INPUT VOLTAGE?

If the input voltage is too high, it can put undue stress on the inverter, leading to a potential hazard. By limiting the PV input voltage, our inverters can help mitigate these risks

Get a quote

A Input-Series

This paper presents the configuration and control strategy for input-series- and output-parallel- (ISOP) connected inverter system, which is constructed by connecting multiple

Get a quote

Understanding inverter voltage

An abnormally high inverter output voltage may indicate a malfunction in the voltage regulation circuit. Addressing this issue promptly is crucial to prevent potential damage

Get a quote

What You Need To Know About a High Volt Inverter

A high-voltage inverter is designed to convert DC power into AC at a higher voltage than a standard inverter. It can accept inputs from high-voltage power sources and

Get a quote

How To Read And Interpret An Inverter Specification

Input Voltage Input voltage indicates the DC voltage required to operate the inverter. Inverters generally have an input voltage of 12V, 24V, or 48V. The

Get a quote

Guess what you want to know

-

What is the general input voltage of the inverter

What is the general input voltage of the inverter

-

Inverter working output voltage is high

Inverter working output voltage is high

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Small high voltage inverter

Small high voltage inverter

-

Inverter high voltage side and low voltage side

Inverter high voltage side and low voltage side

-

High voltage 100 000V inverter

High voltage 100 000V inverter

-

Inverter high voltage front stage

Inverter high voltage front stage

-

270v high voltage DC to 220v inverter

270v high voltage DC to 220v inverter

-

The impact of high voltage on inverter

The impact of high voltage on inverter

-

Can the inverter convert low voltage into high voltage

Can the inverter convert low voltage into high voltage

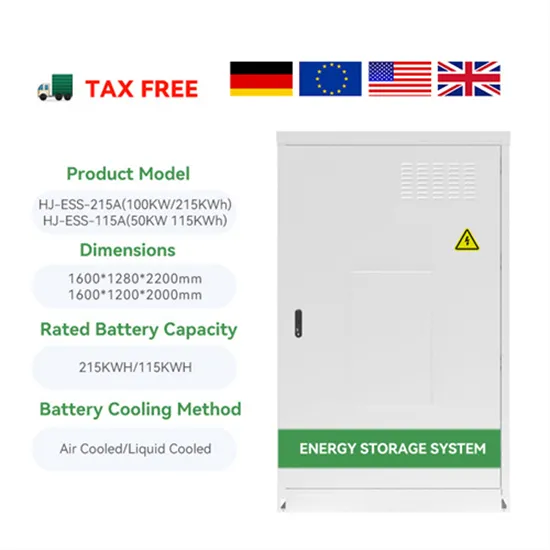

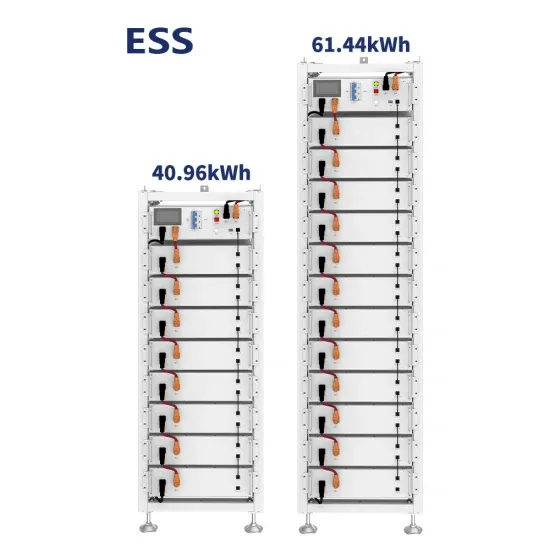

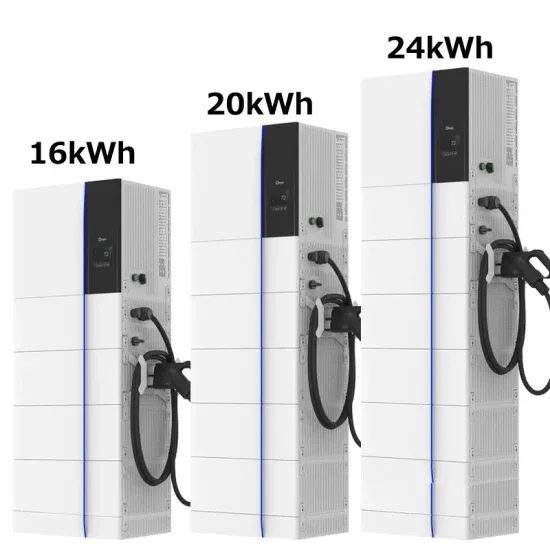

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.