What Is An Inverter? | Definition, Types, Uses, How It

An inverter is a vital electrical device that converts direct current (DC) into alternating current (AC), which is used to power many household

Get a quote

Voltage Inverter : Circuit, Working and Its Applications

Generally, many people have confused on voltage inverter and converter, and their working principles. An inverter is an electrical device,

Get a quote

How to Read Solar Inverter Specifications

The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

Get a quote

6.5. Efficiency of Inverters | EME 812: Utility Solar

6.5. Efficiency of Inverters The efficiency of an inverter indicates how much DC power is converted to AC power. Some of the power can be lost as heat, and

Get a quote

What Is an Inverter: Inverter Ratings, Efficiency & More

Power inverters are one of the most important components in an independent energy system. Get all the information you need about inverters here.

Get a quote

Technical White Paper SolarEdge Single Phase Inverter

Basic System Operation m differs from traditional PV systems in that the SolarEdge inverter operates at a constant DC input voltage regardless of the number of power optimizers wired in

Get a quote

Understanding inverter voltage

The start inverter voltage is the minimum input voltage required for the inverter to initiate the conversion process. In the case of a 12V inverter, the start inverter voltage is

Get a quote

Definition of Inverter Specifications

Maximum Input Voltage DC (V). This indicates the maximum voltage that can be input on the DC side of the inverter. Nominal Voltage (AC). This indicates the nominal voltage that is output

Get a quote

Inverter Current Calculator, Formula, Inverter Calculation

Inverter Current Formula: Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the load, the

Get a quote

Inverter input voltage: what it means, choosing the right one

Learn about inverter input voltage and how to choose the right hybrid or voltronic solar inverter in Pakistan. Discover top tips and why ANICSUN leads the market.

Get a quote

A comprehensive guide to inverter voltage

The input voltage is the DC voltage that the inverter receives from an external power source. The external power source can come from a variety

Get a quote

Power Inverters: The Need-to-Know Essentials

Key Takeaways Learn basic inverter input and output schemes The variety of inverters and how they''re created Uses for consumer power inverters and additional

Get a quote

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power calculations and inverter

Get a quote

Power Inverter Basics

What is the power inverter typical inputs? Of course, it is DC supply voltage, but with different values, it may be small like 12V DC, 24V DC, 48V DC, or medium like 200V DC,

Get a quote

Introduction to inverters: structure, operating principles and

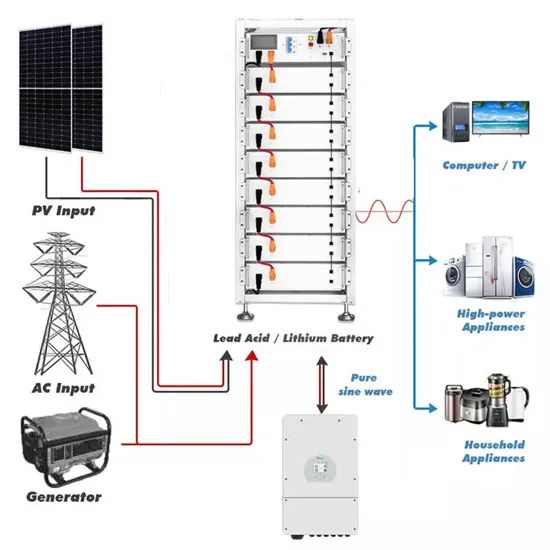

DC input: The DC input of the inverter receives DC power input from the power source or battery. This part usually includes input connectors, input protection circuitry, etc.

Get a quote

A comprehensive guide to inverter voltage

The input voltage is the DC voltage that the inverter receives from an external power source. The external power source can come from a variety of sources, including

Get a quote

What Is Inverter Voltage?

The input voltage 1 of an inverter refers to the voltage level at which it receives energy. This is typically DC (direct current) power coming from a battery or solar panel system.

Get a quote

Power inverter

200 to 400 V DC, when power is from photovoltaic solar panels. 300 to 450 V DC, when power is from electric vehicle battery packs in vehicle-to-grid systems. Hundreds of thousands of volts,

Get a quote

Designing an Efficient Power Inverter Circuit

Learn how to build a power inverter circuit diagram to convert DC power into AC power for various applications. Step-by-step guide and circuit diagram.

Get a quote

Inverter Voltage Calculator, Formula, Inverter Voltage Calculation

The output voltage of an inverter is determined by the DC input voltage and the modulation index. The modulation index represents the ratio of the inverter''s AC output voltage to its maximum

Get a quote

How To Read And Interpret An Inverter Specification

Input voltage indicates the DC voltage required to operate the inverter. Inverters generally have an input voltage of 12V, 24V, or 48V. The inverter selected must match the power source,

Get a quote

Efficiency of Inverter: Calculation & Equation Guide

The efficiency of an inverter refers to the amount of AC output power it provides for a given DC input. This normally falls between 85 and 95 percent, with 90 percent being the average.

Get a quote

How To Read And Interpret An Inverter Specification

Input voltage indicates the DC voltage required to operate the inverter. Inverters generally have an input voltage of 12V, 24V, or 48V. The

Get a quote

Inverter Voltage Calculator & Formula Online Calculator Ultra

Inverter voltage calculation is critical in the design and analysis of power electronics systems. It aids in selecting appropriate components, ensuring system efficiency, and

Get a quote

6 FAQs about [What is the general input voltage of the inverter ]

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

What voltage is used for inverter?

Small input voltages like 12V, 24V, 48V DC are used for inverters used in running small applications like mobilE charger and home appliances / devices. Medium input voltages like 200V DC, 450V DC, 1000VD C are used for inverters used in photo-voltaic solar panels systems and electrical cars chargers.

What are the input specifications of a solar inverter?

The input specifications of an inverter concern the DC power originating from the solar panels and how effectively the inverter can handle it. The maximum DC input voltage is all about the peak voltage the inverter can handle from the connected panels. The value resonates with the safety limit for the inverter.

How does a power inverter work?

The input voltage, output voltage and frequency, and overall power handling depend on the design of the specific device or circuitry. The inverter does not produce any power; the power is provided by the DC source.

What is the AC output voltage of a power inverter?

The AC output voltage of a power inverter is often regulated to be the same as the grid line voltage, typically 120 or 240 VAC at the distribution level, even when there are changes in the load that the inverter is driving. This allows the inverter to power numerous devices designed for standard line power.

What is a high voltage power inverter?

High input voltages like 100000V DC or higher are used for inverters used in high voltage DC power transmission stations / lines. What is the power inverter typical outputs? There are 3 parameters that will define the output of power inverter, and they are the frequency, the voltage, and power capacity.

Guess what you want to know

-

Influence of input voltage on inverter

Influence of input voltage on inverter

-

What does a wide voltage inverter mean

What does a wide voltage inverter mean

-

What voltage is best for the inverter

What voltage is best for the inverter

-

Inverter input voltage becomes low

Inverter input voltage becomes low

-

What voltage does the inverter change

What voltage does the inverter change

-

Power frequency inverter changes to wide voltage input

Power frequency inverter changes to wide voltage input

-

What is the tracking voltage of the inverter

What is the tracking voltage of the inverter

-

Input voltage high inverter

Input voltage high inverter

-

What is the voltage of the photovoltaic inverter

What is the voltage of the photovoltaic inverter

-

DC panel inverter input voltage

DC panel inverter input voltage

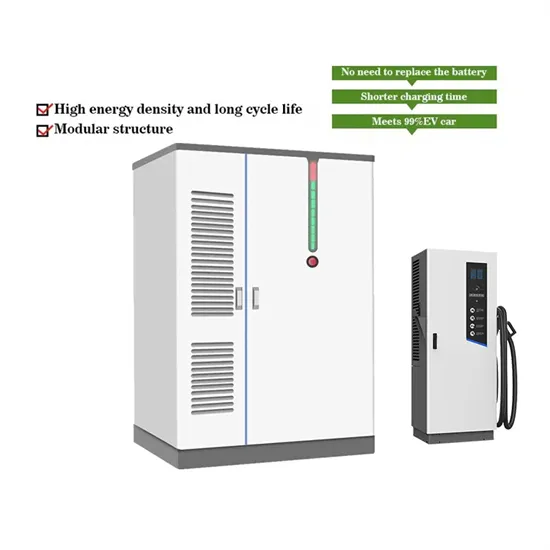

Industrial & Commercial Energy Storage Market Growth

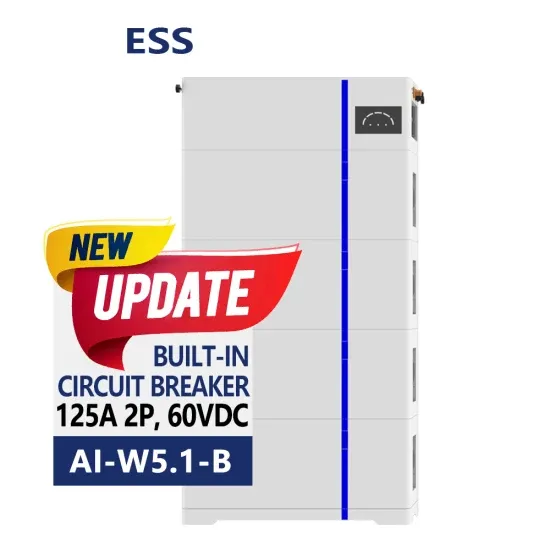

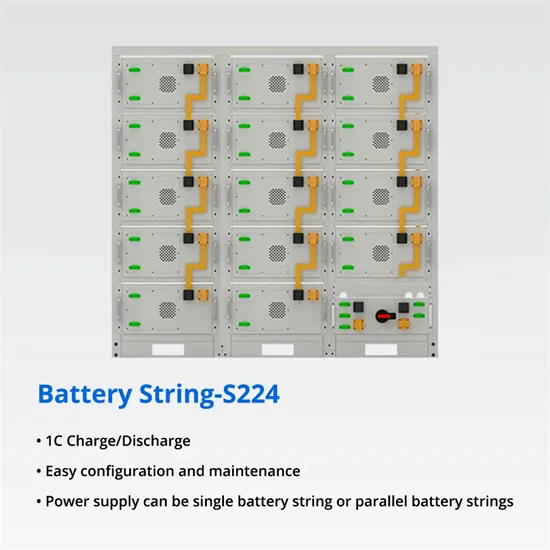

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.