Understanding Inverter Voltage: Definition, Functions,

Inverter voltage, uses, types of inverters based on voltage, and tips on choosing the best inverter voltage for you are mentioned in this article.

Get a quote

MOS INVERTERS: STATIC CHARACTERISTICS

The general shape of the VTC in Fig. 5.4 is qualitatively similar to that of the ideal inverter transfer characteristic shown in Fig. 5.2. There are, however, several significant differences that

Get a quote

How to Address Inverter Low Voltage Issues for

In this article, we explore practical strategies to address inverter low voltage issues, ensuring reliable and efficient operation in demanding

Get a quote

How to Address Inverter Low Voltage Issues for Reliable

In this article, we explore practical strategies to address inverter low voltage issues, ensuring reliable and efficient operation in demanding environments. Understanding Inverter

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always

Get a quote

Inverter Voltage Drop Issue – How to Solve

Whenever PWM is employed in an inverter for enabling a sine wave output, inverter voltage drop becomes a major issue, especially if the parameters are not calculated

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always working efficiently!

Get a quote

Troubleshooting Inverter Problems: A Step-by-Step Guide

However, when inverters malfunction, it can disrupt operations and cause significant inconvenience. In this guide, we will walk you through the process of diagnosing

Get a quote

Summary of common causes and countermeasures of inverter

Common causes and countermeasures of inverter failures Causes of inverter undervoltage failure: 1. Power supply phase loss Cause: When the inverter power supply phase is lost, the three

Get a quote

Inverter model: Input and Output

Even with a very low irradiance, the array MPP voltage becomes significant. The Pthresh power may be understood as the power required for the Inverter internal circuits consumption.

Get a quote

Low voltage out of inverter — northernarizona-windandsun

Hi, I''ve got a small off-gid system that uses a Xantrex DR1512 inverter. Yesterday I checked the voltage on the AC output side and was only getting 100 volts.

Get a quote

Voltage Troubles? A Guide to Diagnosing Inverter Low Voltage

Are you experiencing voltage troubles with your inverter? Don''t worry, you''re not alone. Many people face issues with inverter low voltage at some point in their lives. In this

Get a quote

Types of Power Inverters And How To Choose

The battery voltage must match the inverter input voltage. Output voltage: North American and some South American countries, as well as places such as Japan and Thailand,

Get a quote

[SOLVED]

Pure sine wave inverters can stabilize the output voltage by changing the bus voltage and don''t change the PWM signal that is fed to the full bridge driver. Other option is to

Get a quote

Inverter and Types of Inverters with their Applications

High voltage using low rating devices: using multilevel inverter, high AC voltage can be generated using low voltage rating devices. In case of traditional

Get a quote

10 common inverter failure and the solutions –

This article will give you an overall guide on the reasons of 10 common inverter failure and the solutions step by step to solve these problems.

Get a quote

Multiplus DC Input Low Shutdown and Restart Range

I want to set the DC Input low shutdown on the inverter to around 12.4 volts but this means the DC input low restart value is a whole 1 volt higher at 13.4 volts due to the limitations

Get a quote

10 common inverter failure and the solutions – TYCORUN

This article will give you an overall guide on the reasons of 10 common inverter failure and the solutions step by step to solve these problems.

Get a quote

Power Inverter Troubleshooting – Common Problems and How

One of the most frequent problems with power inverters is low input voltage. This occurs when the battery supplying power to the inverter is not providing enough voltage for the

Get a quote

Interpreting inverter datasheet and main parameters | AE 868

Inverter Input voltage range and max voltage Inverters are designed to operate within a voltage range, which is set by the manufacturer''s specification datasheet. In addition, the datasheet

Get a quote

Three Common Faults in PV Inverters and Their

Wiring Faults: Damaged, short-circuited, or disconnected DC cables between the modules and inverter can cause voltage transmission issues or abnormal

Get a quote

Inverter voltage output declines

That said, most inverters will stop outputting when output voltage drops below 108 volts. Finding it at 8 volts suggests the inverter is defective. Paul Bristol - In the Wind.

Get a quote

What happens if the input high and input low of Buf2 become the

1 It seems you are asking about differences in the definitions of the high and low for output and input. The point is that Buf2 must have its input signal in its input voltage defined space to

Get a quote

6 FAQs about [Inverter input voltage becomes low]

Do inverters have low voltage problems?

Properly grounding your inverter is crucial to avoid voltage fluctuations. In conclusion, inverter low voltage problems are not uncommon, but with the right knowledge and approach, they can be resolved. By understanding the causes behind such issues and following the appropriate diagnostics, you can get your inverter back to working optimally.

What happens if a solar inverter is too low?

The open circuit voltage of the string should be much greater than the minimum input voltage of the inverter; if there are too few modules in series, the open circuit voltage of the string will be too low, resulting in no display on the inverter screen. Solution: Increase the number of solar panels in series.

Why is my inverter screen not working?

Reason 3: The DC input voltage is too low. When the string output voltage is lower than the minimum input voltage of the inverter, there is no display on the inverter screen. To make sure, you can use a multimeter to measure the output voltage of the photovoltaic string to see whether the voltage reaches the minimum input voltage of the inverter.

How do I know if my inverter is low voltage?

If you are experiencing inverter low voltage problems, it's essential to diagnose the issue accurately. Start by checking the battery health. Measure its voltage output using a multimeter to ensure it is within the recommended range. If the reading is below the recommended level, it's time to replace the battery.

What causes low DC input voltage?

Common causes and solutions for low DC input voltage: The open circuit voltage of the string should be much greater than the minimum input voltage of the inverter; if there are too few modules in series, the open circuit voltage of the string will be too low, resulting in no display on the inverter screen.

What is inverter low voltage?

Now that we know what inverter low voltage is, let's explore some common causes behind it. One prevalent cause could be a faulty battery. An old or damaged battery may not be able to provide sufficient power, leading to low voltage from the inverter. Another possible cause could be an inadequate power source or improper electrical connections.

Guess what you want to know

-

Single-phase high and low voltage inverter

Single-phase high and low voltage inverter

-

Middle East low voltage inverter manufacturer

Middle East low voltage inverter manufacturer

-

Can the inverter convert low voltage into high voltage

Can the inverter convert low voltage into high voltage

-

Portugal low voltage inverter prices

Portugal low voltage inverter prices

-

Influence of input voltage on inverter

Influence of input voltage on inverter

-

Libya low voltage inverter manufacturer

Libya low voltage inverter manufacturer

-

Greek low voltage inverter manufacturer

Greek low voltage inverter manufacturer

-

1v input voltage inverter

1v input voltage inverter

-

Inverter voltage high and low

Inverter voltage high and low

-

Panama low voltage inverter price

Panama low voltage inverter price

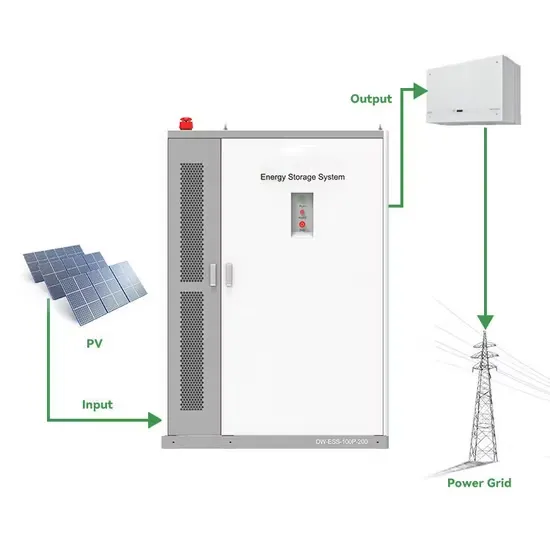

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.