High Voltage Inverter: Unlocking the Potential of High-Power

The main characteristic of a high-voltage inverter is that it has a high operational voltage. This type of inverter is designed to be able to handle high voltages that can reach hundreds or

Get a quote

CHAPTER 2

source inverters. A voltage–fed inverter (VFI) or more generally a voltage–source inverter (VSI) is one in which the dc source has small or negligible impedance. The voltage at the input

Get a quote

High Voltage Inverter Design

By the PWM control chip and high voltage driver IR2110 SG3525A consisting frequency inverter, small size, easy to control, energy utilization efficiency.

Get a quote

Harmonics and Noise in Photovoltaic (PV) Inverter and the

1. Introduction PV inverters use semiconductor devices to transform the DC power into controlled AC power by using Pulse Width Modulation (PWM) switching. PWM switching is the most

Get a quote

High-voltage VS Low-voltage Inverters: What''s the difference?

High-voltage inverters are designed to work with DC voltages typically ranging from 150V to 600V or even more. They are common in larger residential or commercial solar

Get a quote

How do inverters convert DC electricity to AC?

Inverters can also be used with transformers to change a certain DC input voltage into a completely different AC output voltage (either higher or

Get a quote

The Best Off-Grid Power Inverters Reviewed

6 days ago· Comparing the Efficiency and Power Output of the Best Off-Grid Power Inverters In the world of off-grid power inverters, efficiency and power

Get a quote

High Voltage Inverter: Unlocking the Potential of High

The main characteristic of a high-voltage inverter is that it has a high operational voltage. This type of inverter is designed to be able to handle

Get a quote

High Voltage Inverter: What They Are, How They Work, and

What is a High Voltage Inverter? A high voltage inverter is a device that converts the direct current (DC) electricity from solar panels or batteries into high voltage alternating current (AC)

Get a quote

Inverter and Types of Inverters with their Applications

The output voltage and current waveform of the inverter circuit, vo, and io respectively, are assumed to be AC quantities. These are stated in terms of

Get a quote

High Voltage Inverter Design

By the PWM control chip and high voltage driver IR2110 SG3525A consisting frequency inverter, small size, easy to control, energy utilization efficiency. This system has now been used in

Get a quote

Inverter too high output voltage than normal, problem?

It has a detection voltage range of 180V to 260V and turns on when the electricity voltage is higher or lower when it is set to UPS Mode. Its detection mode is higher (they do not

Get a quote

High Voltage Inverters: Understanding Its Benefits and Applications

High-voltage inverters play a crucial role in converting DC (direct current) into AC (alternating current) at higher voltage levels, making them ideal for various applications such

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

What is a High Voltage Inverter? A high voltage inverter is a device that converts the direct current (DC) electricity from solar panels or batteries into high

Get a quote

Understanding inverter voltage

An abnormally high inverter output voltage may indicate a malfunction in the voltage regulation circuit. Addressing this issue promptly is crucial to prevent potential damage

Get a quote

An advanced guide to Understanding DC to AC inverters

Various electronics have an input of either 12, 24, or 28 DC voltage, and in order to use appliances with an AC output voltage, you must have a power inverter. Among the more

Get a quote

Inveter AC output voltage too high?

What the heck? I am afraid it''s my inverter that has been damaging my appliance. I open up this fan and got it running again, but it seem it doesn''t run as fast as it use to run. My 6000BTU

Get a quote

How Does Input Voltage Affect a Grid-Tie Inverter?

However, the component series connected voltage is generally not so high, and the circuit needs to be adjusted. The grid tie inverter is generally

Get a quote

Maximizing Energy Efficiency: How to Use an Inverter to Its Full

The output voltage of an inverter is the voltage that is produced by the inverter and sent to the load, such as a motor or a lighting circuit. Most inverters allow you to adjust the output voltage

Get a quote

The 3 Most Common Faults on Inverters and how to Fix Them

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage. This is caused by a high intermediate circuit DC voltage. This

Get a quote

How to Troubleshoot and Fix Common Inverter Problems

Here are some steps to follow: Check the input voltage. The input voltage to the inverter should be within the specified range. If the input voltage is too low or

Get a quote

The 3 Most Common Faults on Inverters and how to

At IDS we have a wealth of inverter experience. We have been an ABB Partner for over 20 years and are used to supporting clients with a variety of inverter

Get a quote

Types of Inverters

This ensures a smooth and strong AC output. Transformer (Optional): Inverters used in high-strength packages can also include transformers to alter the voltage stages of the

Get a quote

The Technology Behind High Input Voltage Inverters

High input voltage inverters are designed to handle voltages higher than their conventional counterparts. They typically have a wide input voltage range, making them

Get a quote

6 FAQs about [The inverter has a high voltage output]

What is the main circuit of an inverter?

The main circuit of an inverter includes an inverter DC power supply, IGBT bridge inverter, protection circuits, high frequency high voltage transformers, and high frequency high voltage silicon stack (Rectifier).

What causes a DC inverter to overvoltage?

This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage. There are other causes of DC overvoltage, however. POSSIBLE FIXES: Turn the overvoltage controller is on. Check supply voltage for constant or transient high voltage. Increase deceleration time.

How does a high-voltage full bridge inverter work?

A high-voltage full bridge inverter works by converting the DC voltage V1 to a high-frequency square wave AC voltage. This AC voltage is then supplied to a 20kHz frequency high-voltage transformer T1, which, after the boost rectifier, provides power to the load. The inverter high-voltage full bridge drives the routing components and the IGBT power modules.

What are the most common faults on inverters?

In this article we look at the 3 most common faults on inverters and how to fix them: 1. Overvoltage and Undervoltage Overvoltage This is caused by a high intermediate circuit DC voltage. This can arise from high inertia loads decelerating too quickly, the motor turns into a generator and increases the inverter’s DC voltage.

What is the input voltage of an inverter?

Understanding the inverter voltage is crucial for selecting the right equipment for your power system. Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function optimally. What is the rated input voltage of an inverter?

What causes low output inverter voltage?

Low output inverter voltage can stem from issues such as a weak battery, loose connections, or internal faults. Thoroughly troubleshooting these aspects can help identify and rectify the cause of low output inverter voltage. Why is inverter output voltage so high?

Guess what you want to know

-

Is the inverter voltage output high or low

Is the inverter voltage output high or low

-

Inverter working output voltage is high

Inverter working output voltage is high

-

Imported high voltage inverter wholesale

Imported high voltage inverter wholesale

-

Armenia high voltage inverter

Armenia high voltage inverter

-

High voltage battery connected to inverter

High voltage battery connected to inverter

-

1 5v high voltage inverter

1 5v high voltage inverter

-

Is there voltage on one side of the inverter output

Is there voltage on one side of the inverter output

-

The maximum voltage output by the inverter

The maximum voltage output by the inverter

-

High voltage inverter parameters

High voltage inverter parameters

-

Low voltage inverter high voltage grid connection

Low voltage inverter high voltage grid connection

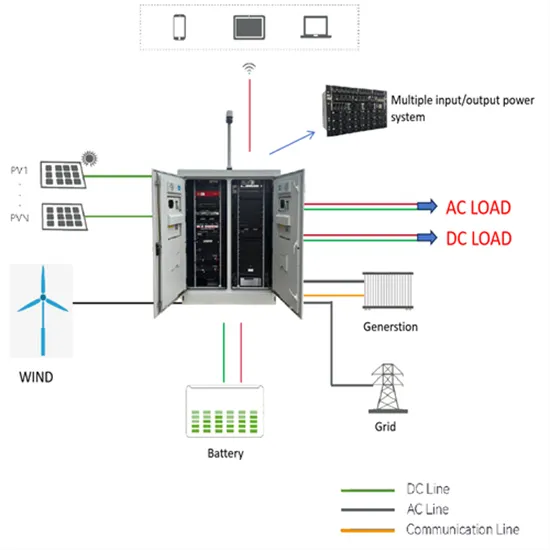

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.