Easily Evaluate High-Voltage Motor Systems in Your Lab

Figure 1. High voltage motor control solution system configuration Inverter Board Overview The inverter board allows users to evaluate motor control using a high-voltage

Get a quote

6.4. Inverters: principle of operation and parameters

These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time. For example, very narrow (short) pulses simulate a low

Get a quote

SUN-5/6/8/10/12/15/20/25K-SG01HP3-EU-AM2 Inverter

Remotely shutdown function Smart Monitoring Platform Thanks to the smart monitoring platform, Deye full series inverter products support remotely shutdown immediately

Get a quote

Estimation of voltage distribution on the inverter fed random

The high electrical stresses in the Electrical Insulation Systems of machines fed by pulse width modulation (PWM) inverters remain a limitation of the lifetime. The stress is caused by

Get a quote

Comprehensive Guide to Inverters: Types, Parameters and

Discover everything you need to know about inverters, from understanding the difference between pure sine wave and modified sine wave to choosing the right inverter type

Get a quote

dynamic model review guideline for inverter based

Introduction The guideline is developed from WECC Solar Photovoltaic Power Plant Modeling and Validation Guideline[1] and incorporated the CAISO interconnect requirements for inverter

Get a quote

Solar Power Inverter 50kw Hybrid On-Off Grid Inverter

The Solar Power Inverter 50kW Hybrid On-Off Grid Inverter is a versatile and high-performance solution for large-scale solar energy systems. Featuring 4 integrated MPPTs with a string

Get a quote

High Voltage Inverter: Unlocking the Potential of High-Power

This article will discuss the definition, working principles, characteristics, and benefits of using high voltage inverter in renewable energy systems.

Get a quote

Understanding inverter voltage

In the realm of power electronics, the inverter voltage is a critical parameter that dictates its performance, compatibility, and safety. Understanding the intricacies of inverter

Get a quote

Decoding Inverter Parameters (Part I)

In previous editions, we discussed two critical indicators on the PV side of an inverter: the maximum over-sizing ratio and the maximum PV input

Get a quote

Parameters for Integrating an Inverter

Before integrating an inverter into any electrified system, three parameters must be locked in: number of phases, system voltage, and motor phase currents. These factors drive

Get a quote

Voltage Ride-Through

The inverter has three high voltage ride-through setpoints, with one instantaneous trip voltage setting, configurable to the following ranges (measured as line to neutral):

Get a quote

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power calculations and inverter

Get a quote

High Voltage Inverter: Unlocking the Potential of High

This article will discuss the definition, working principles, characteristics, and benefits of using high voltage inverter in renewable energy

Get a quote

High Voltage Inverters: Understanding Its Benefits and Applications

High-voltage inverters play a crucial role in converting DC (direct current) into AC (alternating current) at higher voltage levels, making them ideal for various applications such

Get a quote

40kW~60kW Three-Phase High Voltage Hybrid Inverter

40kW~60kW Three-Phase High Voltage Hybrid Inverter SSE-HH40K~60K-P3EU three-phase high-voltage hybrid inverter offers high efficiency for commercial and industrial energy storage.

Get a quote

What are the Important Parameters of an Inverter?

High power output, fewer units, easy management; fewer components, better stability, and easier maintenance. 2. Low harmonic distortion, high power quality;

Get a quote

Working principle of high voltage inverter

The control strategy and optimization of high-voltage inverters are the key to improving their performance and stability. By introducing advanced control algorithms (such as

Get a quote

HV510 Series High-Performance Inverter Selection Manual

including HV350 series low-voltage general purpose inverter, HV510 series low-voltage high-performance inverter, HV500 series low- voltage engineering single transmission inverter,

Get a quote

Improving power quality and efficiency of multi-level inverter

Conventional power conversion systems often face challenges with harmonic distortion and electromagnetic interference (EMI), particularly when handling high power. Multi

Get a quote

What Are the Core Parameters of High-Voltage DC

Discover key parameters of high-voltage DC contactors, including voltage ratings, current capacity, contact resistance, and insulation strength

Get a quote

6.4. Inverters: principle of operation and parameters

These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time. For example, very narrow

Get a quote

Decoding Inverter Parameters (Part I)

In previous editions, we discussed two critical indicators on the PV side of an inverter: the maximum over-sizing ratio and the maximum PV input voltage. Now, we will take

Get a quote

Guess what you want to know

-

High voltage inverter model

High voltage inverter model

-

High voltage inverter 500w

High voltage inverter 500w

-

Ghana high voltage inverter manufacturer

Ghana high voltage inverter manufacturer

-

12v high voltage pulse inverter

12v high voltage pulse inverter

-

How much power does a high voltage inverter have

How much power does a high voltage inverter have

-

High Voltage Inverter Kit

High Voltage Inverter Kit

-

ASEAN high voltage inverter 220v

ASEAN high voltage inverter 220v

-

Imported high voltage inverter wholesale

Imported high voltage inverter wholesale

-

Armenia high voltage inverter

Armenia high voltage inverter

-

Honduras High Voltage Inverter

Honduras High Voltage Inverter

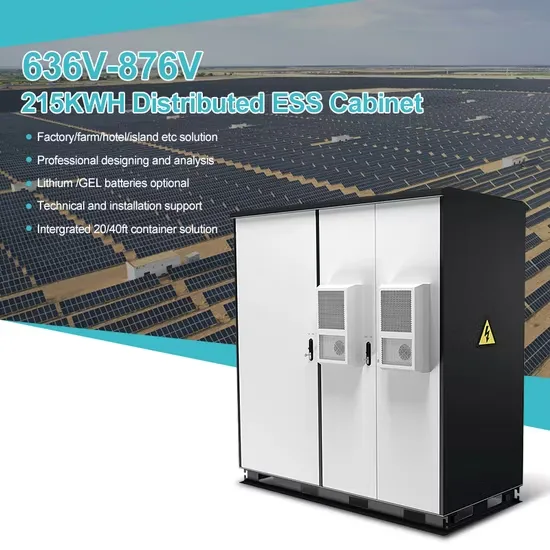

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.