When choosing an inverter, what voltage ratings

Maximum input voltage is the threshold that your inverter can handle without damage. This value is particularly important when integrating solar panels with

Get a quote

Voltage Control Methods of Inverter – PWM Technique

In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage. The block diagram representation

Get a quote

Why there is no output voltage after the inverter is powered on?

According to the working flow of the inverter circuit, the driving pulse required by the inverter circuit is generated by the CPU and is amplified by the drive circuit. Therefore, the

Get a quote

Sizing solar inverters to prevent voltage drops

Voltage drop considerations The minimum wire size obtained above doesn''t take into account voltage drops due to long runs between the array and inverter and between the

Get a quote

Single Phase Output Inverter Troubleshooting

Troubleshooting a single-phase output inverter involves identifying potential issues and applying appropriate solutions. Here are some common

Get a quote

How does your inverter deal with ground.

Folks, When setting up an inverter, one of the more important safety things to get correct is the grounding and the neutral-Ground bond. All of the inverters have a grounding lug

Get a quote

How to Read Solar On Grid Inverter Data Sheet? | inverter

7. Starting voltage: It refers to minimum DC voltage required to start the grid tie inverter. Below this value, inverter will not work, so designer always keep an eye on this value

Get a quote

Single-Phase & Three-Phase Inverters: Function and Operation

The input or dc side of the inverter is usually called the ''dc link'', reflecting the fact that in most of the cases the dc is obtained by rectifying the incoming constant-frequency utility

Get a quote

Ground Fault Basics and Inverter Grounding

The one ground wire connection in this AC wiring discussion is a connection to the inverter''s high output terminal strip. The terminal strip

Get a quote

Common faults and solutions of inverters

First, measure the output port of the inverter and check if there are any problems on the output side of the inverter. If there is no problem, it is a circuit breaker on the external AC side.

Get a quote

Inverter connection guide

If you''ve studied our article on transformers, you''ll know that they''re electromagnetic devices that change low-voltage AC to high-voltage AC, or vice-versa, using two coils of wire (called the...

Get a quote

INVERTERS

[The nomenclature ''inverter'' is sometimes also used for ac to dc converter circuits if the power flow direction is from dc to ac side. However in this lesson, irrespective of power flow direction,

Get a quote

Inverter connection guide

If you''ve studied our article on transformers, you''ll know that they''re electromagnetic devices that change low-voltage AC to high-voltage AC, or vice-versa, using two coils of wire

Get a quote

Single-Phase & Three-Phase Inverters: Function and Operation

Basically, the output voltage and frequency are controlled in much the same way as for the single-phase inverter however the output consists of three identical waveforms

Get a quote

Inverter : Operating Principle,Circuit, Classification

Single Phase Inverter A single-phase inverter or also called as half-bridge inverters, converters DC supply to single-phase AC supply. For

Get a quote

Why is there only one wire going to the inverter and why is there a

Typically 230v AC. It is detached from the grid and cannot be connected to the grid. This usually works as a pass though, meaning that the relays are closed to the grid while

Get a quote

Understanding inverter voltage

An abnormally high inverter output voltage may indicate a malfunction in the voltage regulation circuit. Addressing this issue promptly is crucial to prevent potential damage

Get a quote

How To Read And Understand Solar Inverter Specifications

Inverter Power Output: One of the most critical specs to focus on is the power output rating, which tells you the maximum load the inverter can handle. This is usually

Get a quote

Voltage Control Methods of Inverter – PWM Technique

In this method of control, an ac voltage controller is connected at the output of the inverter to obtain the required (controlled) output ac voltage.

Get a quote

Common neutral architecture inverters vs others

Naively, I would have thought it''s 240V, so you can split off a solution for 240V, that doesn''t have to worry about neutral, and then do a regular tier split phase HF for 120V. And

Get a quote

How to create a ''neutral'' for an off-grid 1-phase inverter 1

If one side of the inverter output may be safely grounded, that will emulate the common 120 Volt residential circuit and may cure the issues. If the inverter output is not

Get a quote

Inverter Current Calculator, Formula, Inverter Calculation

Inverter Current Formula: Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the load, the

Get a quote

Why there is no output voltage after the inverter is

According to the working flow of the inverter circuit, the driving pulse required by the inverter circuit is generated by the CPU and is amplified by the

Get a quote

Single Phase Output Inverter Troubleshooting

Troubleshooting a single-phase output inverter involves identifying potential issues and applying appropriate solutions. Here are some common problems, their possible causes,

Get a quote

6 FAQs about [Is there voltage on one side of the inverter output ]

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

How do inverter circuits work?

In this, the inverter circuit is fed from a constant dc voltage source and a controlled ac voltage is obtained at the output terminals by turning ON and OFF the switching components in the inverter circuit. The main drawback of this method is that it requires very low turn-ON and turn-OFF time thyristors which are very expensive.

What do you need to know about input power inverters?

Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V.

How do inverter input and output work?

They work by converting the power obtained from the DC source, which is the input source of the inverter, into AC, which is the output source of the inverter, and then distributing it to various devices that require AC sources. In this article, we will discuss inverter input and output and their relationships. What is an Inverter Input?

What are the characteristics of an output inverter?

The output produced by the inverter is an alternating current (AC) that is usually used to power various kinds of electronic devices needed in everyday life such as lights, fans, televisions, and so on. Here are some characteristics of the output inverter. Output Voltage: must match the connected device to prevent damage.

How does AC side inverter work?

The output of ac side is taken from terminals A and B. The operation of this inverter is as follows: When transistors 1 and 4 are switched ON, the load voltage is positive, and equal to the dc link voltage, while when 2 and 3 are ON it is negative. If no devices are switched ON, the output voltage is zero.

Guess what you want to know

-

Inverter output voltage is slow

Inverter output voltage is slow

-

How much is the inverter output voltage adjusted to

How much is the inverter output voltage adjusted to

-

Is the inverter voltage output high or low

Is the inverter voltage output high or low

-

What is the inverter s continuous output voltage

What is the inverter s continuous output voltage

-

The maximum voltage output by the inverter

The maximum voltage output by the inverter

-

Inverter output voltage returns to zero

Inverter output voltage returns to zero

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

Inverter voltage output is too low

Inverter voltage output is too low

-

The inverter has a high voltage output

The inverter has a high voltage output

-

Is the inverter output voltage 233v normal

Is the inverter output voltage 233v normal

Industrial & Commercial Energy Storage Market Growth

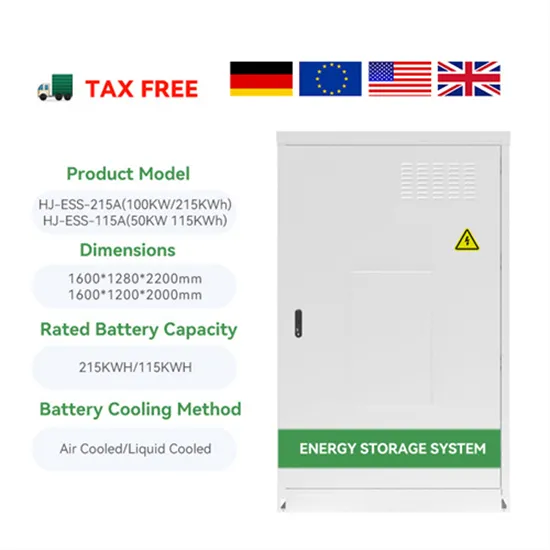

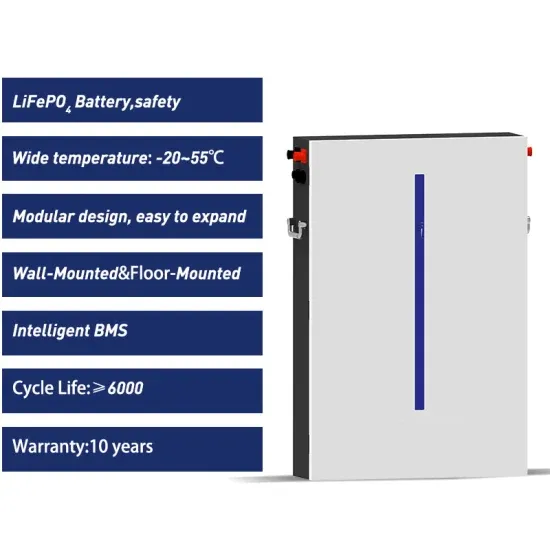

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.