High-frequency Inverter Design for a Wide Range of Resistive and

Abstract: This paper proposes a design methodology for a high-frequency resonant inverter module consisting of two inverters in parallel to deliver constant output power with

Get a quote

A High Performance High Frequency Inverter Architecture with

In this work, a high frequency inverter system that can work in a wide range of inductive or capacitive load is proposed, which includes Class D inverter, novel active impedance

Get a quote

Full Inverter vs Dual Inverter:What are the difference?

A dual inverter, on the other hand, splits power between critical and non-critical loads. This means your must-have devices, like medical gear, stay on during

Get a quote

High-Frequency Inverter: How They Work and Why

Yes, high-frequency inverters are commonly used in off-grid solar systems due to their lightweight design, high efficiency, and compatibility with

Get a quote

Low Frequency VS High Frequency Inverter

The choice between a low-frequency and high-frequency inverter will depend on your specific needs, such as the type of loads you expect to power and the conditions in which

Get a quote

High frequency verses low frequency inverters

What is the difference between high, or low frequency inverters the pros and cons? I have seen a few posts someone said low was better for high surge load like AC units,

Get a quote

How to Distinguish High Frequency Inverter and Low Frequency

The high frequency inverter can deliver the same power at higher frequency with a much smaller and lighter transformer, as a result, the HF inverter is often called transformer-less inverter, or

Get a quote

How to Distinguish High Frequency Inverter and Low Frequency Inverter

The high frequency inverter can deliver the same power at higher frequency with a much smaller and lighter transformer, as a result, the HF inverter is often called transformer-less inverter, or

Get a quote

High-Frequency Inverter: How They Work and Why They Matter

Yes, high-frequency inverters are commonly used in off-grid solar systems due to their lightweight design, high efficiency, and compatibility with MPPT controllers.

Get a quote

The Advantages and Disadvantages of an Dual

Curious about the advantages of dual inverter AC? This article breaks down its benefits and challenges, helping you choose the best cooling system.

Get a quote

Inverter Specifications and Data Sheet

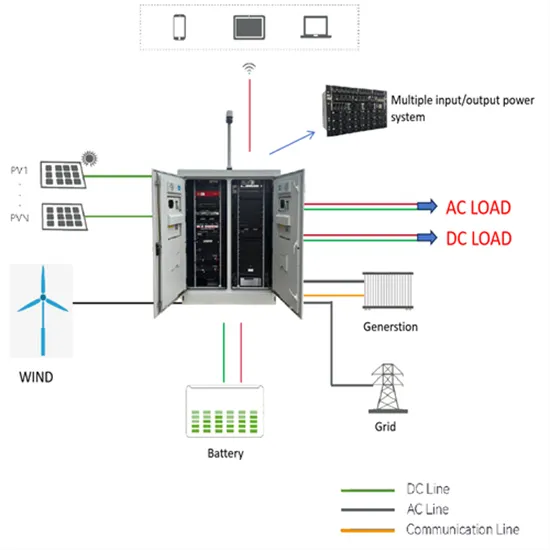

The inverter is connected directly to either the power source (solar PV array or wind turbine) or the charge controller, depending on whether backup storage batteries are used.

Get a quote

Optimal Impedance Design for Dual-Branch High-Frequency Inverter

High-frequency inverters often need to operate under dynamically varying loads, while the inverter structure allows only very narrow loads. In this article, an optimal impedance

Get a quote

Low frequency inverter vs high frequency inverter

When choosing an inverter for your solar system, one of the key decisions is whether to use a low-frequency inverter or a high-frequency inverter. Both types have unique

Get a quote

Microsoft Word

Classic three-phase traction inverter topology is suitable to drive AC traction motors. The three-phase inverter topology with a fewer number of switching devices is good to improve the VPD

Get a quote

Inverter Specifications and Data Sheet

The inverter is connected directly to either the power source (solar PV array or wind turbine) or the charge controller, depending on whether backup storage

Get a quote

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation

Get a quote

Power Frequency Inverter vs. High Frequency

To sum up, variable frequency inverters and high frequency inverters each have their own advantages and disadvantages and are suitable

Get a quote

High Frequency Inverter vs low Frequency Inverter

Introduction What is a High Frequency Inverter? What is a Low Frequency Inverter? Introduction By the early 1980s, pure sine wave inverters had become more commercially available,

Get a quote

Review on Silicon Carbide based High-Fundamental

ABSTRACT This article provides a comprehensive review of Silicon Carbide (SiC) based inverters designed for High-Speed (HS) drive applications, which require higher output frequencies to

Get a quote

High frequency verses low frequency inverters

My previous inverter was not low-frequency and was 2000W. While it could run everything higher powered (like the vacuum), it just seemed to struggle more to do so.

Get a quote

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation and characteristics, and the

Get a quote

High efficiency SiC traction inverter for electric vehicle applications

Silicon Carbide (SiC) MOSFETs, which offer substantial improvements in the device figure of merit, are investigated as alternatives to silicon IGBTs in electric vehicle (EV) drivetrain

Get a quote

FAQ: How does EU Regulation 428/2009 apply to AC

These drives are considered by the U.S. and the EU to be dual-use devices, meaning that although they are commonly used in civilian

Get a quote

FAQ: How does EU Regulation 428/2009 apply to AC drives?

These drives are considered by the U.S. and the EU to be dual-use devices, meaning that although they are commonly used in civilian applications, such as industrial

Get a quote

Selective Dual Duty Cycle Controlled High Frequency Inverter

The output high-frequency AC effective power of the proposed soft-switching high frequency inverter circuit in Fig.1 can be continuously regulated by a constant frequency dual duty cycle

Get a quote

Power Frequency Inverter vs. High Frequency Inverter: Which is

To sum up, variable frequency inverters and high frequency inverters each have their own advantages and disadvantages and are suitable for different application scenarios.

Get a quote

Inversion Methods Explained: High Frequency vs Low Frequency

These inverters are feature rich to include the optional ability to hardwire additional external GFCI outlets, input of multiple DC voltages, provide regulated dual output voltages (120/240VAC),

Get a quote

High Frequency Vs. Low Frequency Inverters... Which is better?

High Frequency Vs. Low Frequency? Which Inverter is better?00:00 - intro00:43 - low frequency inverters02:15 - High Frequency Inverters03:17 - Comparison

Get a quote

Full Inverter vs Dual Inverter:What are the difference?-Shenzhen

A dual inverter, on the other hand, splits power between critical and non-critical loads. This means your must-have devices, like medical gear, stay on during outages, while less important stuff

Get a quote

6 FAQs about [Is the Swedish 299A high frequency inverter a dual silicon inverter ]

What are the different types of inverters?

Inverters are capable of converting direct current (DC) into alternating current (AC) to meet the needs of various electrical equipment and systems. Among them, power frequency inverter and high frequency inverter are two common inverter types, each with different characteristics and application scenarios.

What is a high frequency inverter?

Applications: These inverters are more suitable for off-grid systems where heavy loads and extreme conditions are expected, such as in industrial applications or in remote locations with harsh environments. Weight: High-frequency inverters are lighter than low-frequency inverters, using smaller, lighter transformers.

What is a low frequency inverter?

Efficiency: Low-frequency inverters are known for their robustness and ability to handle high surge currents, making them suitable for powering heavy-duty appliances or equipment with high starting currents, such as motors and compressors.

What does EU Regulation 428/2009 mean for inverters?

And in December 2014, the EU implemented amendments (Annex I) to its dual-use regulation 428/2009, addressing frequency converters (aka converters or inverters). The EU regulation controls the export of drives that have the following performance characteristics: frequency control better (less) than 0.2 %.

What is the output waveform quality of a power frequency inverter?

Output waveform quality: The output waveform quality of power frequency inverters is usually better than that of high frequency inverters. Since the power frequency inverter uses traditional components such as transformers and inductors to transform voltage and current, its output waveform is closer to a sine wave and has lower harmonic content.

What is the difference between a low frequency and high frequency inverter?

Low-frequency inverter: heavy and capable of surge power, lower efficiency, more reliable, expensive. High-frequency inverter: lightweight, not capable of surges, more efficient, less reliable, cheaper. I’m an off-grid enthusiast.

Guess what you want to know

-

Advantages and disadvantages of dual silicon high frequency inverter

Advantages and disadvantages of dual silicon high frequency inverter

-

Small high frequency inverter

Small high frequency inverter

-

52Hz low frequency high efficiency home inverter

52Hz low frequency high efficiency home inverter

-

Uganda high frequency inverter price

Uganda high frequency inverter price

-

How much does a 6kw high frequency inverter cost

How much does a 6kw high frequency inverter cost

-

Inverter high frequency

Inverter high frequency

-

Small inverter produces high frequency

Small inverter produces high frequency

-

Taipei No 3 38000v high frequency inverter

Taipei No 3 38000v high frequency inverter

-

The higher the voltage the higher the high frequency inverter

The higher the voltage the higher the high frequency inverter

-

5kva high frequency power inverter

5kva high frequency power inverter

Industrial & Commercial Energy Storage Market Growth

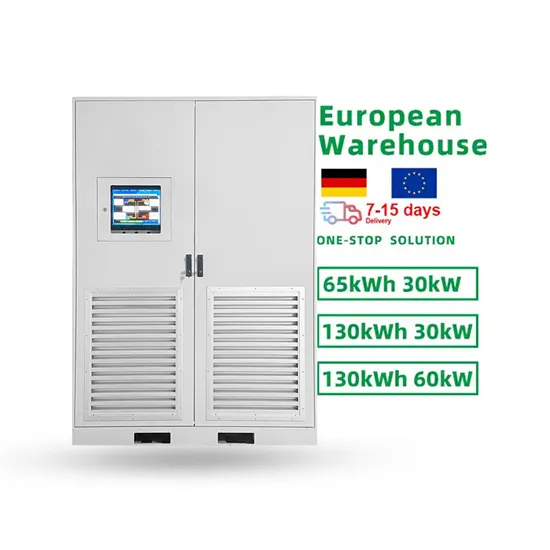

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

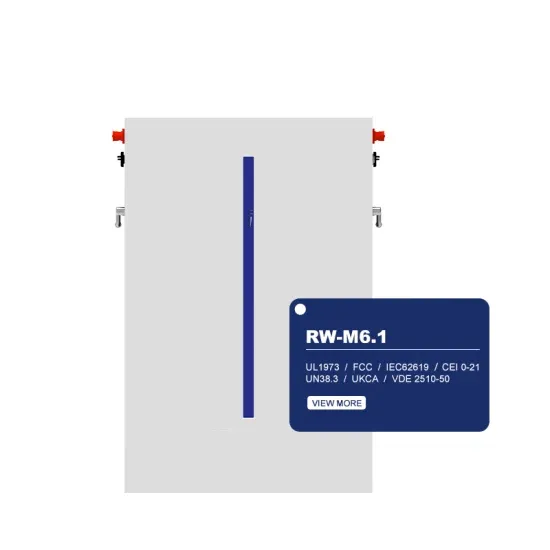

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.