Inverters, Types and Voltages

Key Takeaways Understanding the differences between low voltage and high voltage inverters and low frequency and high frequency inverters ensures you can make an

Get a quote

High frequency inverter vs low frequency inverter

This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size

Get a quote

Technical comparison between Low Frequency

Low-frequency inverters have the advantage over high-frequency inverters in two fields: peak power capacity, and reliability. Low-frequency inverters are

Get a quote

Growatt 3kW Stackable Off-Grid Inverter | SPF 3000TL LVM-48P

Multifunctional off grid solar inverter, integrated with a MPPT solar charge controller, a high frequency pure sine wave inverter and a UPS function module all in one machine. Perfect for

Get a quote

High-Frequency Inverter: How They Work and Why

Regarding small—to medium-sized inverters, the high-frequency inverter is the market-dominating choice due to its high efficiency, compact

Get a quote

Low vs High frequency inverters | DIY Solar Power Forum

If you intend to run high inductive loads such as motors found on AC watermakers, a low frequency inverter will be more reliable. If you just want to run resistive loads like water

Get a quote

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get a quote

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

One of the most critical architectural decisions an engineer faces is the choice between a line-frequency (or low-frequency) and a high-frequency design. This choice has

Get a quote

Learn About High vs. Low Frequency Inverters: Which

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation

Get a quote

Low Frequency vs High Frequency Inverters: Which

Low-frequency inverters have large designs and are equipped with heavy iron-core transformers to handle higher power surges. These heavy-duty

Get a quote

What is the difference between low frequency inverter

If you are in solar business, you must have heard about a lot of inverter companies marketing there inverters as low frequency or high

Get a quote

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation and characteristics, and the

Get a quote

7 Simple Inverter Circuits you can Build at Home

These 7 inverter circuits might look simple with their designs, but are able to produce a reasonably high power output and an efficiency of

Get a quote

High frequency inverter vs low frequency inverter

This article compares high frequency inverter vs low frequency inverter from the aspects of working frequency, components, efficiency, size and weight, etc., and compares

Get a quote

Surge vs. Efficiency: Choosing Between Low and High

One of the most critical architectural decisions an engineer faces is the choice between a line-frequency (or low-frequency) and a high-frequency design. This choice has

Get a quote

High-Frequency vs. Low-Frequency Inverters

2. Size and Weight High-Frequency Inverters: One of the biggest advantages of high-frequency inverters is their compact size and lightweight design. Since they use smaller, lighter

Get a quote

Inverters PCB Manufacturing & Assembly Services

High-Frequency Inverters PCB Design Considerations Designing the PCB for high-frequency inverters requires careful attention to various factors to ensure

Get a quote

High Frequency Inverter vs low Frequency Inverter

Conclusion In conclusion, the choice between high-frequency and low-frequency inverters depends largely on the specific needs of the application. High-frequency inverters offer the

Get a quote

Hi-Flo High-Frequency Off-Grid MPPT Solar Inverter

This latest high-frequency off-grid transformer-less MPPT solar inverter works with or without a battery based on user requirements. It is possible to select

Get a quote

High-Frequency Inverter: How They Work and Why They Matter

Regarding small—to medium-sized inverters, the high-frequency inverter is the market-dominating choice due to its high efficiency, compact size, and ability to deliver stable power.

Get a quote

Hi-Flo High-Frequency Off-Grid MPPT Solar Inverter For Modern

This latest high-frequency off-grid transformer-less MPPT solar inverter works with or without a battery based on user requirements. It is possible to select the desired modes at the time of

Get a quote

Small 600W 500W 400W 300W Pure Sine Wave

Samll pure sine wave inverter 300w 400w 500w 600w pure sine wave inverter for sale. Pure sine wave inverter can work and connect to any type of equipment

Get a quote

High Frequency Vs. Low Frequency Inverters... Which is better?

High Frequency Vs. Low Frequency? Which Inverter is better?00:00 - intro00:43 - low frequency inverters02:15 - High Frequency Inverters03:17 - Comparison

Get a quote

6 FAQs about [Small high frequency inverter]

What is a low frequency inverter?

Efficiency: Low-frequency inverters are known for their robustness and ability to handle high surge currents, making them suitable for powering heavy-duty appliances or equipment with high starting currents, such as motors and compressors.

What is a high frequency inverter?

Applications: These inverters are more suitable for off-grid systems where heavy loads and extreme conditions are expected, such as in industrial applications or in remote locations with harsh environments. Weight: High-frequency inverters are lighter than low-frequency inverters, using smaller, lighter transformers.

What is the difference between a low frequency and high frequency inverter?

Low-frequency inverter: heavy and capable of surge power, lower efficiency, more reliable, expensive. High-frequency inverter: lightweight, not capable of surges, more efficient, less reliable, cheaper. I’m an off-grid enthusiast.

Why are high frequency inverters more efficient?

In contrast, high-frequency inverters can use smaller-sized and lighter-weight components due to their use of higher frequencies, resulting in smaller overall size and weight. Efficiency: Since the high frequency inverter uses high-frequency switches for inversion, its switching loss is relatively small, so it has higher conversion efficiency.

Does victron use a high frequency inverter?

Victron combines both inverters, which they call Hybrid HF or Combined high frequency and line frequency technologies. What frequency inverter does growatt use? Growatt uses a high-frequency inverter. Which one is best? Low or high frequency? The best inverter is the low-frequency inverter.

How much does a high frequency inverter weigh?

That unit (Phocos PSW-H 5kw/120v) weighs around 110 lbs. I'm also considering it for my off-grid build, but I believe high frequency inverters generally weigh less and can double power on a surge for a couple seconds.

Guess what you want to know

-

Small inverter produces high frequency

Small inverter produces high frequency

-

5kva high frequency power inverter

5kva high frequency power inverter

-

High frequency inverter produces 1200v

High frequency inverter produces 1200v

-

Advantages and disadvantages of dual silicon high frequency inverter

Advantages and disadvantages of dual silicon high frequency inverter

-

Taipei No 3 38000v high frequency inverter

Taipei No 3 38000v high frequency inverter

-

Inverter high frequency

Inverter high frequency

-

Photovoltaic inverter high frequency tolerance

Photovoltaic inverter high frequency tolerance

-

Industrial frequency inverter high power solar energy

Industrial frequency inverter high power solar energy

-

Simple sinusoidal high frequency inverter design

Simple sinusoidal high frequency inverter design

-

Zambia high frequency inverter price

Zambia high frequency inverter price

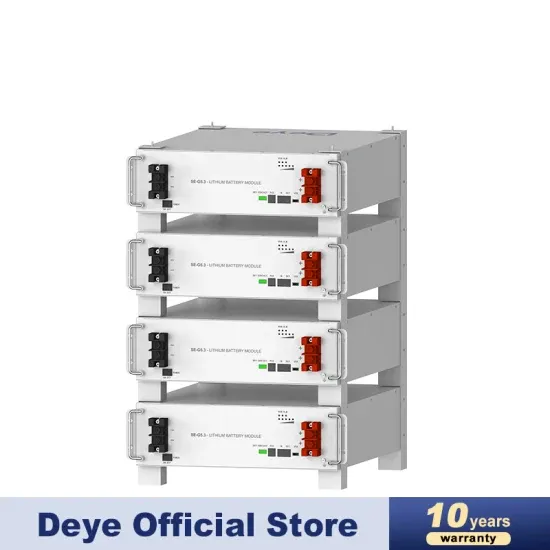

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.