Chapter 7 Homework 1 Flashcards | Quizlet

Technician A says the high-voltage battery is connected to the auxiliary battery through a set of high-voltage relays or contactors. Technician B says the high-voltage system shares the

Get a quote

Inverter Ride through Functions

Fundamentally, ride through is needed to avoid cascade failure of the utility grid during severe under frequency events, and to a lesser degree, severe under voltage events.

Get a quote

What is low voltage ride-through of photovoltaic array

Therefore, the main factor restricting the low voltage ride-through capability of photovoltaic power plants is the AC current output by the

Get a quote

High Voltage Inverter: Unlocking the Potential of High-Power

This article will discuss the definition, working principles, characteristics, and benefits of using high voltage inverter in renewable energy systems.

Get a quote

High Voltage Inverter: Unlocking the Potential of High

This article will discuss the definition, working principles, characteristics, and benefits of using high voltage inverter in renewable energy systems.

Get a quote

High-Voltage Ride-Through (HVRT) and Low-Voltage Ride-Through

Grid-tied inverters, particularly in renewable energy systems (e.g., solar and wind power plants), must comply with grid codes that require them to ride through voltage

Get a quote

Low voltage ride through

Low voltage ride through In electrical power engineering, fault ride through (FRT), sometimes under-voltage ride through (UVRT), or low voltage ride through (LVRT), [1] is the capability of

Get a quote

Volt/VAR Curve & Ride-Through Settings Guidelines

A Volt/Var curve setting is an autonomous grid support function offered by smart inverters in compliance with the IEEE 1547-2018 standard. Volt/VAR settings are the default autonomous

Get a quote

Understanding Inverter Voltage: Definition, Functions,

Inverter voltage, uses, types of inverters based on voltage, and tips on choosing the best inverter voltage for you are mentioned in this article.

Get a quote

What is an Inverter? Working Principle, Types, and Applications

Output: Delivers AC energy at a designated voltage and frequency, making it suitable for powering appliances and equipment. Working Principle of an Inverter An inverter operates by

Get a quote

High Voltage Ride Through (HVRT) in Solar Power Systems

During a ride-through event, the inverter continues to operate under a defined duration of low or high grid voltage. A voltage ride-through is the capability of the inverter to maintain output

Get a quote

High Voltage Ride

The increased penetration of photovoltaic power generation affects the stability of the power system. To increase the fault ride-through capability and reduce the off-grid frequency of the

Get a quote

Research on low/high voltage ride through of PV

Fault ride-through capability is one of the important grid-connection indexes for large-scale generation of PV power and other renewable energy, which is of great significance for the safe

Get a quote

High-voltage VS Low-voltage Inverters: What''s the difference?

You''ll learn what high-voltage and low-voltage inverters do, how they work, and where each type is best used. We''ll also talk about the benefits and drawbacks of each, along

Get a quote

Inverter Protection and Ride-Through : RNWBL Service Line

In addition to voltage control, inverters can be set for reactive current injection during a Fault Ride Through (FRT) event. This feature which tries to increase the positive

Get a quote

DC-to-AC Converters (Inverters): Design, Working &

HVDC Systems: High Voltage Direct Current (HVDC) transmission systems use inverters to convert DC back to AC at the receiving

Get a quote

ROHM and Schaeffler Launch Mass Production of SiC-Based High-Voltage

The Schaeffler inverter subassembly functions as the fundamental power electronics brick that governs the electric drivetrain through logic-based control signals. ROHM

Get a quote

Volt/VAR Curve & Ride-Through Settings Guidelines

ous control function for all inverter-based DERs. In "Volt/VAR mode", also referred to as the inverter''s autonomous voltage control setting, the reactive power (absorption or injection) of

Get a quote

Shoot-through protection for an inverter consisting of the next

Attention has been paid to the next-generation IGBT toward CMOS compatible wafer processes, which can be driven by a 5-V logic level due to its low threshold gate voltage.

Get a quote

Inverter Protection and Ride-Through : RNWBL

In addition to voltage control, inverters can be set for reactive current injection during a Fault Ride Through (FRT) event. This feature which

Get a quote

7 Smart Inverter Tests You Should Get Ready For

Discover everything you need to know about the upcoming UL1741 SA standard for California grid-tied smart inverters. Our comprehensive blog covers essential tests like Voltage

Get a quote

Advanced Power Electronics and Smart Inverters

This project includes a high-voltage silicon carbide-based power block, advanced gate driver, flexible controller board, advanced grid-support control algorithms,

Get a quote

7 Smart Inverter Tests You Should Get Ready For

Discover everything you need to know about the upcoming UL1741 SA standard for California grid-tied smart inverters. Our comprehensive blog

Get a quote

High-Voltage Ride-Through (HVRT) and Low-Voltage

Grid-tied inverters, particularly in renewable energy systems (e.g., solar and wind power plants), must comply with grid codes that require them

Get a quote

Comparing Carrier-Based PWM Techniques in High

High-voltage inverters form an essential part of renewable energy systems, and these inverters rely on pulse width modulation (PWM) to control

Get a quote

High-Voltage Ride-Through Method for Single-Stage Grid

Grid-connected PV inverter plays an important role in solar power applications. Since large-scale switching-off loads and grid faults may lead to voltage swell in the grid, the

Get a quote

32 Common Faults in Inverters and Their Solutions

Discover the top 32 reasons for inverter failure and how to fix them with our comprehensive troubleshooting guide. Ensure your inverter is always

Get a quote

6 FAQs about [Inverter high voltage is through]

How does a fault ride through inverter work?

In addition to voltage control, inverters can be set for reactive current injection during a Fault Ride Through (FRT) event. This feature which tries to increase the positive sequence current while decreasing the negative sequence current. The FRT controls can also be set to simply stop gating the IGBTs durint a fault.

Why does an inverter need to control reactive current?

When the grid voltage rises above its nominal value due to a fault clearance or grid dynamics, the inverter must support voltage regulation by controlling reactive current (Iq). The reason for this approach lies in power system dynamics at high voltages: • Decoupling of Active and Reactive Power:

What is a power inverter & how does it work?

But the inverter does much more having additional functions such as maximum power point tracking (MPPT), grid monitoring, and anti-islanding protection as well as DC to AC conversion to safely feed high quality AC power into the connected grid.

What are grid-tied inverters?

Grid-tied inverters, particularly in renewable energy systems (e.g., solar and wind power plants), must comply with grid codes that require them to ride through voltage disturbances (HVRT/LVRT) without tripping.

How do I set the inverter for a voltage fault?

The inverter can be set to the following modes for voltage faults: Full Dynamic Support – Reactive current feed in, Partial Dynamic Support – Active and reactive current feed in is blocked during the fault and Disable (FRT off) – Inverter will trip on any disturbance. AC trip settings are independent of the PLL.

How do PV inverters support grid frequency?

Grid frequency support is achieved by adjusting inverter real power output. This functionality is limited with PV inverters because the inverters are following the DC energy provided to them by the sun. For a grid high frequency event, PV inverters can be easily set to reduce active power to help reduce the grid frequency.

Guess what you want to know

-

Ethiopia high voltage inverter

Ethiopia high voltage inverter

-

800v high voltage fast charging inverter

800v high voltage fast charging inverter

-

510 000 arc high voltage inverter high power

510 000 arc high voltage inverter high power

-

Belize high voltage inverter manufacturer

Belize high voltage inverter manufacturer

-

High voltage inverter 500w

High voltage inverter 500w

-

Use inverter when voltage is high

Use inverter when voltage is high

-

270v high voltage DC to 220v inverter

270v high voltage DC to 220v inverter

-

The voltage used by the inverter is too high

The voltage used by the inverter is too high

-

Inverter working output voltage is high

Inverter working output voltage is high

-

Inverter high voltage protection setting

Inverter high voltage protection setting

Industrial & Commercial Energy Storage Market Growth

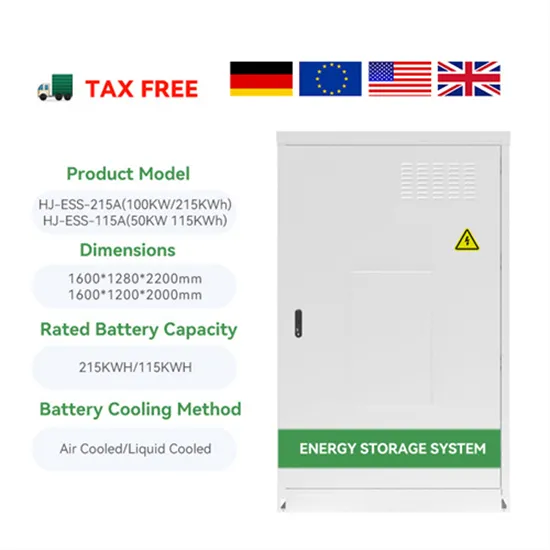

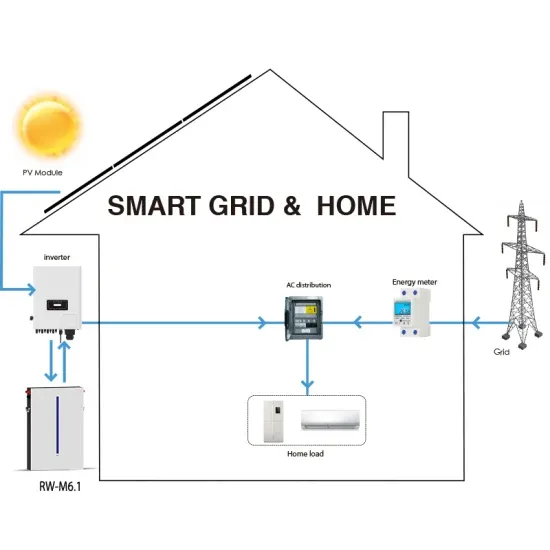

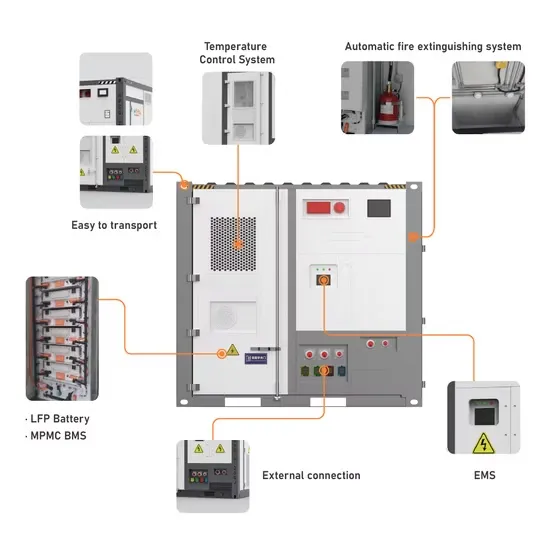

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.