Delphi and Cree Partner on 800V SiC Inverter to Cut

The technology, which supports multi voltage platforms, is an evolution of the company''s proven high-voltage inverter and builds on 25

Get a quote

The new standard of 800V high-power EV inverter – IV5

Recognizing this trend, Punch Powertrain has developed the IV5—a cutting-edge 800V high-power inverter. This product leverages the company''s extensive expertise in

Get a quote

Infineon high voltage Inverter Application Presentation

Infineon high voltage Inverter Application Presentation Traction Inverter trends Semiconductors contribute to improved energy efficiency, but also to size and weight reduction, to improve the

Get a quote

EV Fast-Charging Stations | Vicor | Automotive

Grappling with the EV 400V and 800V charging dilemma? Vicor deliver the surest way to eliminate compatible with any DC fast-charging station.

Get a quote

Power boost with 800V systems – development of high voltage

There are two main advantages in using 800V systems, improving inverter''s efficiency: faster charging as more power is transferred in less time and reduced power losses in the cabling.

Get a quote

The Rise of 800V Electric Vehicles and Role of Silicon Carbide

The Rise of 800V Electric Vehicles and Role of Silicon Carbide Exploring the engineering merits of higher voltage battery systems for next-generation EVs, and the benefits

Get a quote

Here are all the EVs with 800V charging available in

As technology advances, electric cars are improving their fast-charging times. That means less time spent waiting at a DC public charger

Get a quote

800V EV Battery Pack: The Key High-Voltage Parts Explained

800V EV Battery Pack: The Key High-Voltage Parts Explained A Kia EV6 electric car (with an 800V high-voltage lithium ion batteries system) charging in the city. Ever wonder

Get a quote

New Energy Electric Vehicle 800V High Voltage

As the electric vehicle (EV) market rapidly evolves, 800V high-voltage platform technology is emerging as a key industry focus. Compared to

Get a quote

Understanding the 800V High Voltage Platform in Electric Vehicles

Currently, there are relatively few 800V chargers on the market. However, some models are equipped with on-board voltage boosting systems that increase the charging

Get a quote

Junction temperature estimation of a SiC MOSFET module for 800V high

Owing to the active demands of fast charging technology and 800V high-voltage systems in EVs, SiC MOSFET devices with 1200V blocking voltage have gained significant

Get a quote

400V/800V onboard charging | 400V to 800V DC fast-charging

Enabling vehicle electrification with a high density, scalable, modular power solutions. Partnering to create tailored power conversion solutions

Get a quote

XPeng Announces 480 kW Chargers And 800V SiC

XPeng announced the introduction of China''s first 800 V high-voltage mass-production SiC platform, which further boosts efficiency and fast charging.

Get a quote

Solving 400V/800V EV fast-charging compatibility | Vicor

Simple and efficient 400V/800V EV fast-charging compatibility using scalable, bidirectional, high density power modules. Explore Vicor solutions for automotive applications.

Get a quote

Hyundai''s E-GMP Can Use 400/800V DC Chargers

The second one, on the right, is indirect charging from a 400 V DC fast charger, that involves power electronics (inverter) of the Integrated Drive Axle (IDA) to

Get a quote

Delphi and Cree Partner on 800V SiC Inverter to Cut

The new inverter enables electrical systems up to 800 Volts, significantly extending electric vehicle (EV) range and halving charging times

Get a quote

800V EV Charging Explained: The Tech That Makes EVs Charge Twice as Fast

Ever wonder why some EVs charge in 18 minutes? It''s all about 800V architecture. We explain the science in simple terms and show you which cars have it. Use our interactive

Get a quote

High Voltage 800V SiC Inverter | Valeo for automotive

It converts Direct Current (DC) from the battery to Alternative Current (AC) to power the electric Motor. It can also be used in reverse mode

Get a quote

Understanding the 800V High Voltage Platform in

Currently, there are relatively few 800V chargers on the market. However, some models are equipped with on-board voltage boosting systems

Get a quote

New Energy Electric Vehicle 800V High Voltage Technology

As the electric vehicle (EV) market rapidly evolves, 800V high-voltage platform technology is emerging as a key industry focus. Compared to traditional 400V systems, this

Get a quote

Solving 400V/800V EV fast-charging compatibility | Vicor

Simple and efficient 400V/800V EV fast-charging compatibility using scalable, bidirectional, high density power modules. Explore Vicor solutions for

Get a quote

Delphi and Cree Partner on 800V SiC Inverter to Cut EV Charging

The new inverter enables electrical systems up to 800 Volts, significantly extending electric vehicle (EV) range and halving charging times compared with today''s state-of-the-art

Get a quote

Making the Move from 400V to 800V EVs, What Are the Test

Advantages of 800V Significant Improvement in Charging Time Theoretically, double the voltage means the charging time could be halved. Charge 10-80%: 15-18 min vs up to 30 mins using

Get a quote

High Voltage 800V SiC Inverter | Valeo for automotive

It converts Direct Current (DC) from the battery to Alternative Current (AC) to power the electric Motor. It can also be used in reverse mode to charge the battery by transforming

Get a quote

Power boost with 800V systems – development of

There are two main advantages in using 800V systems, improving inverter''s efficiency: faster charging as more power is transferred in less time and

Get a quote

Porsche Debuts World''s First 11 kW Wireless EV Charging

5 days ago· Growing EV fleets create an exponential demand for high-performance IPMs. Shift to High-Voltage 800V Architectures Traditionally, EVs used 400V systems, but automakers are

Get a quote

The Rise of 800V EV Architecture: Benefits and

Higher Voltage, Lower Current: With double the voltage of traditional 400V systems, 800V EVs can deliver the same power using half the

Get a quote

800V High Voltage Platform Research Report, 2022

Research on 800V high voltage platform: the mass production will commence in 2022 800V high voltage platform-based models are a key deployment of OEMs. Hyundai: It takes just 18

Get a quote

800V EV Charging Explained: The Tech That Makes

Ever wonder why some EVs charge in 18 minutes? It''s all about 800V architecture. We explain the science in simple terms and show you

Get a quote

800V High-Voltage Technology Analysis in EV

Explore the advancements in 800V high-voltage technology for new energy vehicles (NEVs) and its benefits over 400V systems, including faster charging, reduced energy

Get a quote

800V Fast Charging: Revolutionizing EV Charging

800V high-voltage fast charging technology is a key upgrade in the electric vehicle (EV) industry, designed to address the challenges of range and charging efficiency.

Get a quote

6 FAQs about [800v high voltage fast charging inverter]

What is 800V EV charging system?

Inquiry: [email protected] The 800V system for EV means the voltage range of the entire vehicle is within 550V and 950V. It can increase the charging speed of EV.

Why do we need 800V inverters?

Growing demand for more electric vehicle efficiency, higher charging convenience with appropriate infrastructure, and reduced charging times leads many car manufacturers to explore and develop new age charging systems and technologies such as 800V inverters enabling higher efficiency and cost-effectiveness.

Are there any 800V Chargers on the market?

Currently, there are relatively few 800V chargers on the market. However, some models are equipped with on-board voltage boosting systems that increase the charging voltage to 800V during the charging process, ultimately achieving fast charging. Inquiry: [email protected]

Can the 800v high voltage platform be used for fast charging?

However, whether the 800V high voltage platform can be used for fast charging during the charging process depends not only on whether the vehicle itself supports 800V, but also on the cooperation of the charging stack. Currently, there are relatively few 800V chargers on the market.

What is a high voltage inverter?

The inverter is the brain at the heart of the powertrain, it controls the electric motor. It converts Direct Current (DC) from the battery to Alternative Current (AC) to power the electric Motor.

How fast can an 800V Charger charge a car?

An 800V car can accept much higher power levels (up to 350kW) from a compatible DC fast charger. This can mean charging from 10% to 80% in under 20 minutes —turning a lunch break into a full charge. More Consistent Performance: Because the system generates less waste heat, the charging speed is more stable and reliable.

Guess what you want to know

-

Inverter output 800v voltage

Inverter output 800v voltage

-

12v high voltage pulse inverter

12v high voltage pulse inverter

-

1000kv high voltage pulse inverter price

1000kv high voltage pulse inverter price

-

Inverter 24v flash charging wide voltage

Inverter 24v flash charging wide voltage

-

High voltage inverter model

High voltage inverter model

-

North Korea high voltage inverter

North Korea high voltage inverter

-

Inverter 24v super fast charging

Inverter 24v super fast charging

-

Inverter voltage high and low

Inverter voltage high and low

-

12v to 220v inverter fast charging

12v to 220v inverter fast charging

-

600kv high voltage inverter

600kv high voltage inverter

Industrial & Commercial Energy Storage Market Growth

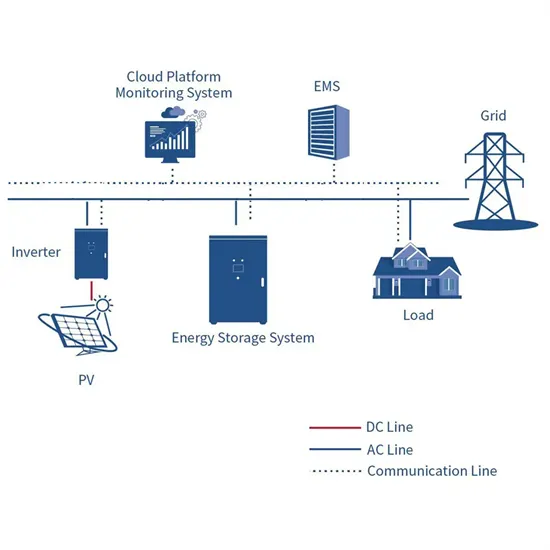

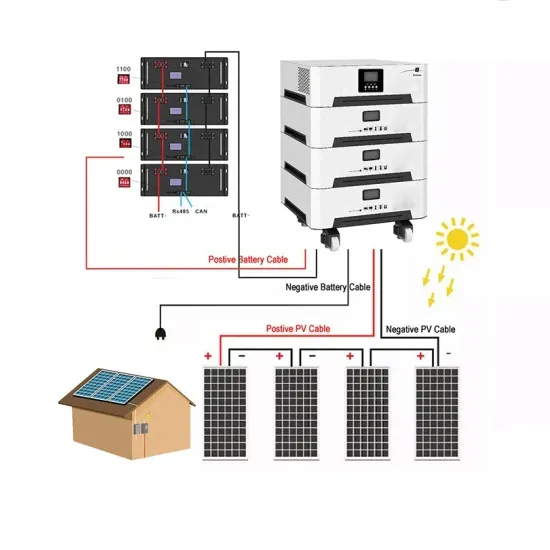

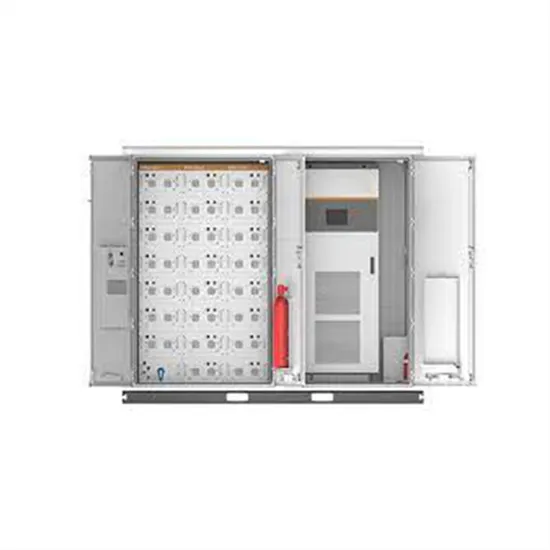

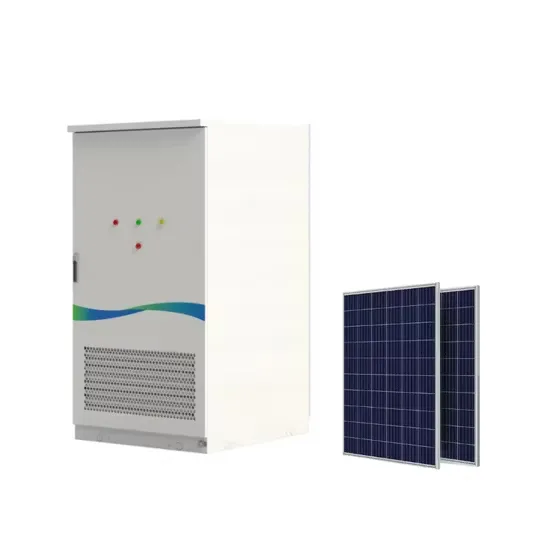

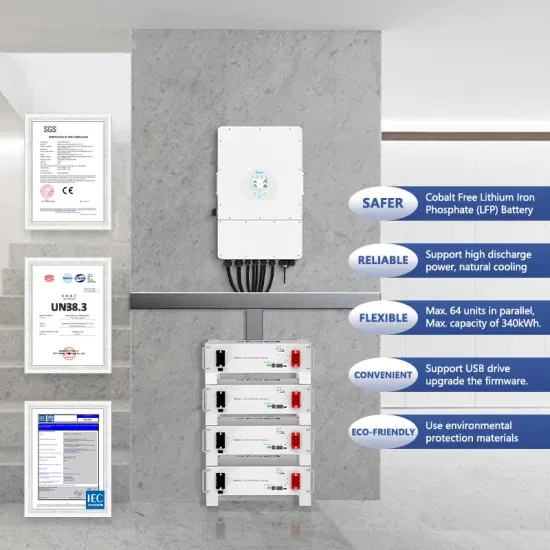

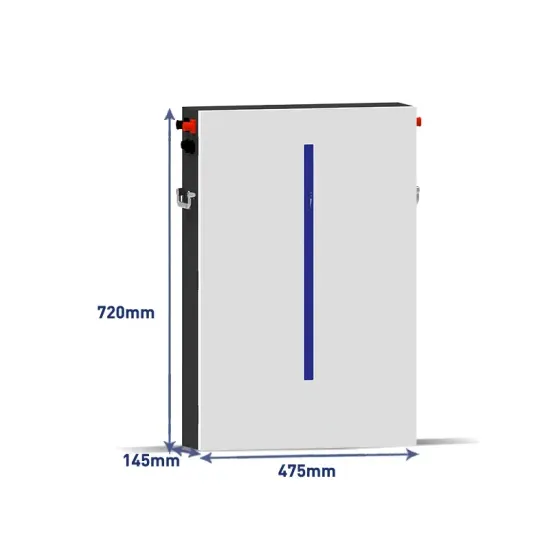

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.