The Design and Research of Three-Phase Inverter Dual-Loop

A dual-loop (inner current loop and outer voltage loop) control scheme for micro electric source inverters in microgrid is improved in this paper. In order to make dual-loop control analysis

Get a quote

Dual-loop Control Strategy for Grid-connected Inverter with

The dual-loop control strategy for grid-connected in-verter with LCL filter in this paper can be used to control the currents of three phase grid-connected inverter, and it will let grid-connected

Get a quote

Dual-loop Control Strategy for Grid-connected Inverter with LCL Filter

Theoretically, the outer loop (the DC voltage controller) should have a smaller bandwidth than the inner loop (the current controller). In practice, these parameters are

Get a quote

Design of a Univariate Dual‐Loop Voltage System Based on the

In this paper, a univariate active-damping double-loop control structure based on voltage feedback is introduced, which aims to address the delay issues associated with digital

Get a quote

Adaptation of Commercial Current-Controlled Inverters for

In this paper, we propose a dual-loop control architecture that allows inverters with current controllers to be re-purposed for voltage control mode operation with VOC.

Get a quote

Passivity-Based Dual-Loop Vector Voltage and Current Control

This letter proposes a passivity-based dual-loop vector voltage and current control method for grid-forming voltage-source converters (GFM-VSCs). A passive outp.

Get a quote

Adaptive robust dual-loop control for voltage and current in

Considering that parallel inverters systems often face with various disturbances, this study proposes a new adaptive robust control strategy for a voltage-current dual-loop to enhance

Get a quote

Design of a Univariate Dual‐Loop Voltage System

In this paper, a univariate active-damping double-loop control structure based on voltage feedback is introduced, which aims to address the

Get a quote

Modeling and Analysis of Multiple Inverters With Dual-Loop

In this article, a voltage and current dual-loop control structure augments the VOC to compensate for these voltage deviations and regulate the inverter output variables directly.

Get a quote

The Design and Research of Three-Phase Inverter Dual-Loop Control

A dual-loop (inner current loop and outer voltage loop) control scheme for micro electric source inverters in microgrid is improved in this paper. In order to make dual-loop control analysis

Get a quote

Dual loop control for single phase PWM inverter for distributed

The current is regulated by inner loop, and inverter voltage is controlled by outer loop. The inner loop is used for regulating the filter inductor current or filter capacitor current.

Get a quote

Dual Voltage-Current Control to Provide Grid-Forming

as short-circuits or overloads could cause currents that are far higher than the rated current. As the semiconductors used in power electronics are highly sensitive to overcurrents, this paper

Get a quote

Dual-loop Control Strategy for Grid-connected Inverter

Theoretically, the outer loop (the DC voltage controller) should have a smaller bandwidth than the inner loop (the current controller). In practice,

Get a quote

6 FAQs about [Voltage and current dual-loop inverter]

How synchronous frame DQ control based double loop control for single phase inverter?

In this paper the design of synchronous frame DQ control based double loop control for single phase inverter in distributed generation system is proposed. For synchronous frame control, the orthogonal signal is generated by second order generalized integrator method.

What control techniques are used for standalone inverter?

Various control techniques are used for standalone inverter such as repetitive control , dead-beat control , and discrete-time sliding-mode control . The response of repetitive control is slow and variation of load is to be continuously monitored.

What is a passivity-based dual-loop vector voltage and current control method?

Abstract: This letter proposes a passivity-based dual-loop vector voltage and current control method for grid-forming voltage-source converters (GFM-VSCs). A passive output impedance of GFM-VSC is guaranteed in both the voltage control mode and the current-limiting mode with a wide range of time delay.

What is a dual-loop control system?

In Dual-loop control systems, the inner capacitor current feedback control and outer synchronous frame control is used to achieve better performance with zero steady state error. The better performance of load is achieved by providing load current as an additional feedback instead of using inductor current feedback.

What is the design of inner current loop?

Design of inner current loop Usually, there are two inner loops using current as feedback. One loop uses the inductor current i L1 as feedback and another loop uses capacitor current ic as feedback. The load current feedback is also included in the capacitor current feedback.

Do three phase inverters produce sinusoidal currents during faulty condition?

Moreover, that the control scheme of three phase inverter are not able to produce sinusoidal currents during faulty condition due to unbalance in the three phase systems. Therefore, controller for single phase inverters is proposed here.

Guess what you want to know

-

Inverter voltage outer loop current inner loop

Inverter voltage outer loop current inner loop

-

60kw inverter grid-connected current and voltage

60kw inverter grid-connected current and voltage

-

Pulse inverter output voltage

Pulse inverter output voltage

-

Solar wide voltage inverter

Solar wide voltage inverter

-

Voltage Source Inverter Power-On Sequence

Voltage Source Inverter Power-On Sequence

-

How much should the inverter voltage and frequency be adjusted

How much should the inverter voltage and frequency be adjusted

-

DC panel inverter input voltage

DC panel inverter input voltage

-

Constant voltage grid-connected inverter

Constant voltage grid-connected inverter

-

How to measure the output current and voltage of the battery cabinet

How to measure the output current and voltage of the battery cabinet

-

Universal dual voltage 48v 60v inverter

Universal dual voltage 48v 60v inverter

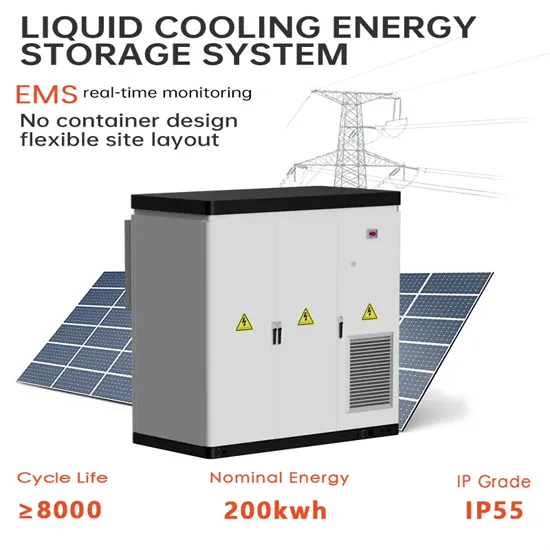

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.