How much frequency can the inverter control the

What are the inverter control methods? The five most common ways in which an inverter controls a motor are as follows: The output voltage of low-voltage

Get a quote

Mastering These 16 Frequency Inverter Parameter

Therefore, debugging a frequency inverter begins with correctly setting its parameters. Here are 16 basic methods for setting inverter

Get a quote

Frequency inverter parameters setting

It is used to compensate the inconsistencies between the external setting signal voltage and the frequency inverter internal voltage (+10v); at the same time it''s convenient for voltage selection

Get a quote

What should I do if the frequency of the inverter external

Confirm whether the frequency signal source parameters of the inverter are set correctly. The frequency signal source of the inverter can be a panel, potentiometer, voltage, current or host

Get a quote

Mastering Inverter Switching Frequencies: A

Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our

Get a quote

The highest frequency and basic frequency of the

When the output voltage of the frequency converter is equal to the rated voltage, the minimum output frequency is called the basic frequency.

Get a quote

The highest frequency and basic frequency of the

Its specific meaning varies slightly depending on how the frequency is given: a. When the frequency is given by the keyboard, the

Get a quote

Converting Generator Frequencies to 60 Hz and 50 Hz Power

Learn how to adjust your generator''s output to 50 Hz or 60 Hz by changing engine RPM or using frequency converters for diverse applications.

Get a quote

Advanced Inverter Drive Parameter Settings

Inverter drives are essential for industrial automation, providing precise motor control, energy efficiency, and system flexibility. While basic

Get a quote

The highest frequency and basic frequency of the inverter

When the output voltage of the frequency converter is equal to the rated voltage, the minimum output frequency is called the basic frequency. The fundamental frequency is

Get a quote

9. Inverter Settings

This is a safe value because any small peak will be compensated by the inverter and the excessive power will not overload the input circuit protection. Be very careful with this setting

Get a quote

Advanced Inverter Drive Parameter Settings

While basic parameters like voltage, frequency, and acceleration are well-known, advanced parameter settings allow for greater performance optimization, system protection,

Get a quote

When a Frequency Inverter Is Used to Control a Motor, What Frequency

The appropriate frequency for controlling a motor with a frequency inverter largely depends on the specific application and the motor''s design. For most standard motors, the frequency range of

Get a quote

Mastering Inverter Switching Frequencies: A Comprehensive Guide

Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our comprehensive guide, your blueprint to

Get a quote

Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get a quote

Introduction to Grid Forming Inverters

Why do we need Grid-forming (GFM) Inverters in the Bulk Power System? There is a rapid increase in the amount of inverter-based resources (IBRs) on the grid from Solar PV, Wind,

Get a quote

Inverter controlled electric motor, how much frequency can be

When using a frequency converter, the output voltage and frequency of the converter are gradually added to the motor, so the starting current and impact on the motor

Get a quote

Setting Inverter for Motor Voltage and Frequency

Learn how to correctly configure an inverter for a motor''s voltage and frequency rating by verifying compatibility, configuring parameters, checking motor connection, setting

Get a quote

TIG Welder Settings and Waveform Controls Explained

AC Output Frequency Conventional technology limits AC frequency to either 50 Hz or 60 Hz, the same as single-phase input power. Inverter technology allows output frequency

Get a quote

How much frequency can the inverter control the

When the frequency converter is adjusted to a frequency greater than 50Hz, the output torque of the motor will decrease. The usual motor is designed and

Get a quote

Advanced Inverter Drive Parameter Settings

While basic parameters like voltage, frequency, and acceleration are well-known, advanced parameter settings allow for greater performance

Get a quote

How much frequency can the inverter control the motor be adjusted

When the frequency converter is adjusted to a frequency greater than 50Hz, the output torque of the motor will decrease. The usual motor is designed and manufactured according to the

Get a quote

Mastering These 16 Frequency Inverter Parameter Settings Will

Therefore, debugging a frequency inverter begins with correctly setting its parameters. Here are 16 basic methods for setting inverter parameters for reference:

Get a quote

Inverter controlled electric motor, how much frequency can be adjusted?

When using a frequency converter, the output voltage and frequency of the converter are gradually added to the motor, so the starting current and impact on the motor

Get a quote

How to Optimize Your Inverter Settings for Solar Panels

5. Adjust the AC Output Frequency AC output frequency must match the grid frequency to maintain system stability. Variations in frequency can cause

Get a quote

6 Important Parameters Setting of VFD

Maximum frequency refers to the highest frequency that the VFD & motor system can operate. As the maximum frequency of variable frequency drive may be higher, when the allowable

Get a quote

When a Frequency Inverter Is Used to Control a

The appropriate frequency for controlling a motor with a frequency inverter largely depends on the specific application and the motor''s design. For most standard

Get a quote

"How to Change Grid, Voltage, and Frequency Range on Solis

Description: In this tutorial, we''ll guide you step-by-step on how to change the grid settings, voltage, and frequency range of the Solis S6 Hybrid Inverter. Whether you''re an installer or a

Get a quote

6 FAQs about [How much should the inverter voltage and frequency be adjusted ]

Can inverter frequency be adjusted or programmed?

Additionally, the inverter frequency can be adjusted or programmed in certain types of inverters, allowing for versatility in different applications. However, the inherent design limitations and operating parameters of the inverter may impose constraints on the achievable inverter frequency range. 3.

What is the basic frequency of an inverter?

The frequency corresponding to the maximum output voltage of the inverter is called the basic frequency; b. When the output voltage of the frequency converter is equal to the rated voltage, the minimum output frequency is called the basic frequency. The fundamental frequency is represented by fBA.

Why is inverter switching frequency important?

The inverter switching frequency in electric motors, particularly in applications like electric vehicles (EVs) or industrial machinery, plays a crucial role in determining the efficiency, performance, and overall reliability of the system.

What are inverter parameters?

Inverter parameters include motor power, current, voltage, speed, and maximum frequency, all of which can be directly obtained from the motor nameplate. Resonance might occur at certain frequency points, particularly with taller structures. When controlling compressors, it's crucial to avoid frequencies that could cause surge.

What is inverter switching frequency?

The inverter switching frequency refers to the rate at which power electronic switches, such as Insulated Gate Bipolar Transistors (IGBTs) or Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs), cycle on and off.

What factors affect inverter frequency?

Several factors influence the inverter frequency, including the design of the power electronics, the configuration of the control circuitry, and the specifications of the utility grid. In grid-tied inverters, for instance, the inverter frequency is typically synchronized with the utility grid to ensure compatibility and seamless energy transfer.

Guess what you want to know

-

How much is the inverter output voltage adjusted to

How much is the inverter output voltage adjusted to

-

How much power does a high voltage inverter have

How much power does a high voltage inverter have

-

High-frequency inverter voltage and frequency

High-frequency inverter voltage and frequency

-

Photovoltaic inverter power frequency withstand voltage

Photovoltaic inverter power frequency withstand voltage

-

The inverter output high voltage frequency is too low

The inverter output high voltage frequency is too low

-

How much does a 24v 3kw industrial frequency inverter weigh

How much does a 24v 3kw industrial frequency inverter weigh

-

How much voltage protection does the inverter have

How much voltage protection does the inverter have

-

How much voltage does the photovoltaic inverter change to

How much voltage does the photovoltaic inverter change to

-

How much does a 6kw high frequency inverter cost

How much does a 6kw high frequency inverter cost

-

What inverter voltage should be adjusted to

What inverter voltage should be adjusted to

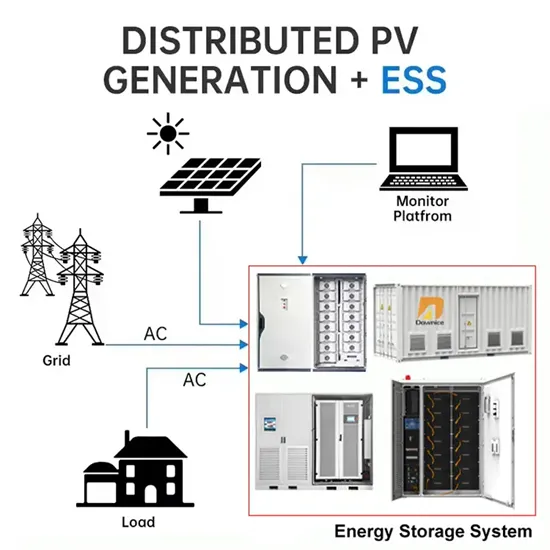

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

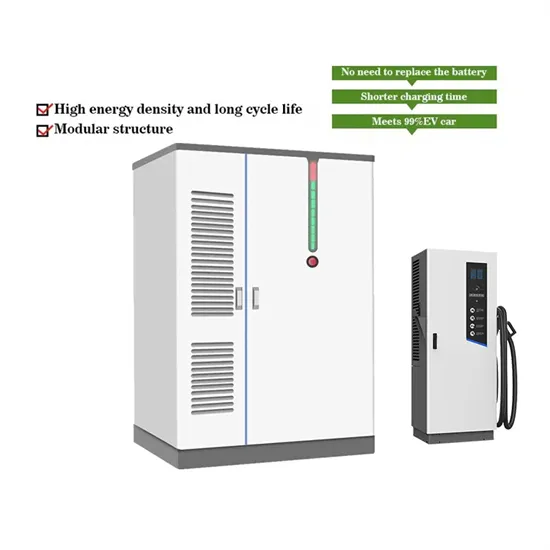

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.