How to Distinguish High Frequency Inverter and Low Frequency Inverter

Low frequency inverter technique is similar to high frequency inverter technique, but produces AC power of a lower frequency and voltage level. Low frequency inverters use pulse width

Get a quote

A Comprehensive Review of High-frequency Transmission Inverters

This paper presents a detailed review of the design aspects and performance analysis of high-frequency inverters used in inductive power transfer application (IPT) for

Get a quote

Learn About High vs. Low Frequency Inverters: Which is Right for

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation and characteristics, and the

Get a quote

Understanding the Difference Between Low Frequency and High

High-frequency inverters and low-frequency inverters are two common types of inverters. They have significant differences in their operation

Get a quote

Review of very high frequency power converters and

With the increasing demand for volume reduction and efficiency improvement, very high frequency (VHF) power converters (30–300 MHz)

Get a quote

High-Frequency Inverter: How They Work and Why

What is a High-Frequency Inverter? A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC)

Get a quote

Advanced Modulation Techniques and Topological Innovations in High

High-Frequency Link inverters (HFLIs) have attracted significant research attention owing to their compact design, high power density, and high efficiency. HFLI systems achieve power

Get a quote

High frequency vs low frequency pure sine wave inverter

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz.

Get a quote

High-Frequency Inverter: How They Work and Why They Matter

What is a High-Frequency Inverter? A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency, typically above

Get a quote

MIT Open Access Articles A High Frequency Inverter for

er design results in systems that are often bulky, expensive, and inefficient. This paper presents the design, physical prototype, controller, and experimental results of a high-frequency

Get a quote

High-Frequency vs. Low-Frequency Inverters

The inverter steps up the voltage using lightweight transformers or inductors, followed by the conversion to AC. Low-Frequency Inverters: Low-frequency inverters use heavy, iron-core

Get a quote

What is a High-Frequency Power Inverter?

High-frequency power inverters utilize high-speed switching at frequencies significantly higher than the standard 50/60 Hz grid frequency. This article provides an overview of high-frequency

Get a quote

Power Frequency Inverter vs High-Frequency Inverter

High-frequency inverters and power-frequency inverters are the two common types of inverters. Each has its own different characteristics and applications, so which one is

Get a quote

High frequency vs low frequency pure sine wave

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few

Get a quote

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Line-Frequency vs. High-Frequency Inverters: A Technical Deep Dive for Engineers In the world of power electronics, the inverter is a cornerstone technology, responsible for the

Get a quote

Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get a quote

Research on High-Frequency Isolated NPC Three

Mining frequency converters are the primary means for achieving variable frequency speed regulation of electromechanical equipment in coal

Get a quote

High Power Factor Induction Heating System with

At present application, cost effective induction heating (IH) using high frequency inverters have been gradually developed for the utility frequency ac to high-frequency ac power conversion

Get a quote

Power Inverter vs. Frequency Inverter | inverter

The adapter converts the AC voltage of the mains power grid into a stable 12V DC output, while the inverter converts the 12V DC voltage output

Get a quote

High-Frequency Inverters: From Photovoltaic, Wind, and

High-Frequency Inverters: From Photovoltaic, Wind, and Fuel-Cell-Based Renewable- and Alternative-Energy DER/DG Systems to Energy-Storage Applications S.K. Mazumder, Sr.

Get a quote

What is a High-Frequency Power Inverter?

High-frequency power inverters utilize high-speed switching at frequencies significantly higher than the standard 50/60 Hz grid frequency. This article

Get a quote

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get a quote

Comparing Carrier-Based PWM Techniques in High

This article explores the potential of carrier-based pulse width modulation techniques such as sawtooth, triangular, and sinusoidal, and

Get a quote

A High-Frequency Resonant Inverter Topology with Low

ESONANT inverters suitable for high frequency oper-Ration have numerous applications, including as radio-frequency power amplifiers [3]–[5], induction heating and plasma generation

Get a quote

Understanding the Difference Between Low Frequency and High Frequency

There are two types of inverters, low frequency and high frequency inverters. Inverters are used in solar power systems, wind turbines, and electric vehicles. In this article,

Get a quote

A Complete Guide to Inverters/Variable Frequency

There are a number of different types of inverters but we will be discussing the type that is used to control electric motors in electrical

Get a quote

6 FAQs about [High-frequency inverter voltage and frequency]

What is a high frequency inverter?

The high frequency inverter converts DC power into AC power using electronic components, such as capacitors and inductors. The high frequency output of a high frequency inverter is ideal for powering electronic devices, such as computers and televisions. High frequency inverters typically have an output of 20kHz or higher.

What is the difference between low frequency and high frequency inverters?

Low frequency inverters generally have a longer lifespan than high frequency inverters due to their more durable components. In conclusion, low frequency and high frequency inverters have their unique features and benefits. Low frequency inverters are ideal for applications that require high power output and can handle heavy-duty appliances.

How do high frequency power inverters convert DC to AC?

High frequency power inverters typically convert the DC to AC by driving the transistors at a much higher frequency from 50 Kilo Hz to a few million Hz. Low frequency inverter circuit diagram

Does victron use a high frequency inverter?

Victron combines both inverters, which they call Hybrid HF or Combined high frequency and line frequency technologies. What frequency inverter does growatt use? Growatt uses a high-frequency inverter. Which one is best? Low or high frequency? The best inverter is the low-frequency inverter.

What are common high-frequency inverter circuit configurations?

Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs. Filter components – Smaller inductors and capacitors possible at high frequencies. Balance size versus performance.

What are the advantages of a high frequency inverter?

High frequency inverters typically have an output of 20kHz or higher. Smaller size and weight compared to low-frequency inverters. Higher efficiency due to reduced power losses. Greater accuracy in output waveform due to the high frequency. Lower electromagnetic interference (EMI) due to higher switching frequency.

Guess what you want to know

-

How much should the inverter voltage and frequency be adjusted

How much should the inverter voltage and frequency be adjusted

-

Off-grid photovoltaic inverter voltage and frequency

Off-grid photovoltaic inverter voltage and frequency

-

The higher the voltage the higher the high frequency inverter

The higher the voltage the higher the high frequency inverter

-

What frequency does a high-frequency inverter require

What frequency does a high-frequency inverter require

-

High frequency inverter voltage can reach

High frequency inverter voltage can reach

-

Maximum operating frequency of high-frequency inverter

Maximum operating frequency of high-frequency inverter

-

Photovoltaic inverter power frequency withstand voltage

Photovoltaic inverter power frequency withstand voltage

-

The difference between high-frequency inverter and industrial frequency inverter

The difference between high-frequency inverter and industrial frequency inverter

-

Power frequency inverter changes to wide voltage input

Power frequency inverter changes to wide voltage input

-

48v industrial frequency sine wave inverter

48v industrial frequency sine wave inverter

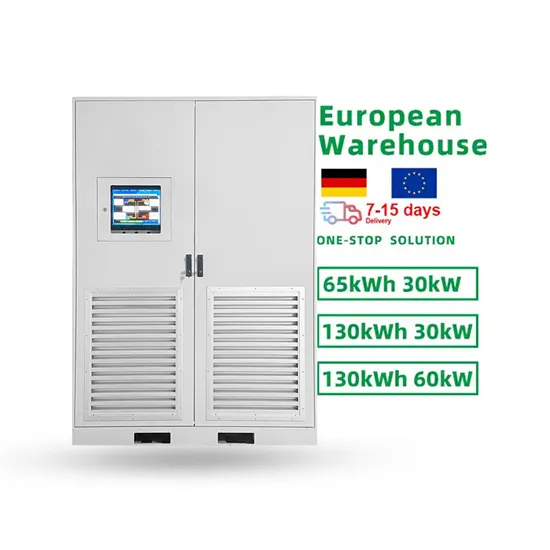

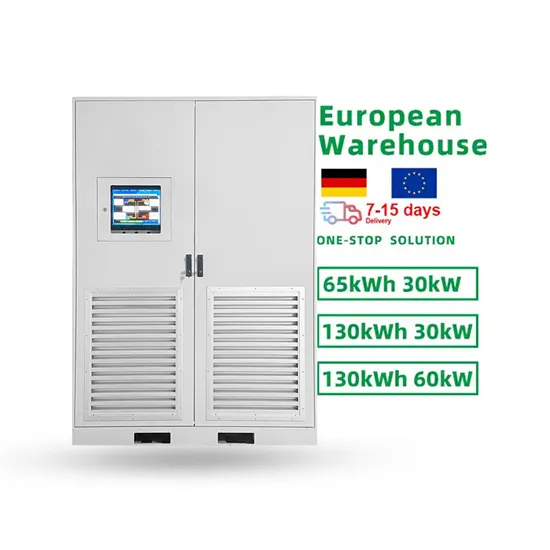

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.