Nine-level high-frequency inverter

However, the switching frequency must reach up to several hundred thousand or even megahertz when used in HFAC output systems. The resulting high switching frequency will inevitably lead

Get a quote

High-Frequency Inverter: How They Work and Why

A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency, typically above 20

Get a quote

Inverter Specifications and Data Sheet

The article provides an overview of inverter functions, key specifications, and common features found in inverter systems, along with an example of power

Get a quote

Low Frequency VS High Frequency Inverter

Discover the differences between low-frequency and high-frequency off-grid inverters, their efficiency, weight, and ideal applications for your solar system.

Get a quote

Nineâ level highâ frequency inverter

Abstract: In the high-frequency AC (HFAC) power distribution system, problems such as high switching frequency, a complicated circuit configuration and difficult parameter design still exist

Get a quote

6.4. Inverters: principle of operation and parameters

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification

Get a quote

Mastering These 16 Frequency Inverter Parameter Settings Will

The typical maximum frequency for inverters is up to 60Hz, with some reaching 400Hz. High frequencies allow motors to operate at high speeds, which can strain the

Get a quote

High-Frequency Inverter: How They Work and Why They Matter

A high-frequency inverter is an electrical device that converts direct current (DC) into alternating current (AC) at a high switching frequency, typically above 20 kHz (Kilohertz), to achieve

Get a quote

The highest frequency and basic frequency of the

The maximum frequency is the maximum frequency that the inverter allows to output, expressed by fmax. Its specific meaning varies

Get a quote

FAQ: How does EU Regulation 428/2009 apply to AC

To this end, the export of high-frequency drives is controlled by U.S. dual-use regulation EAR Category 3, under ECCN 3A225. And in December

Get a quote

Understanding High-Frequency Inverters

In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to transform direct current

Get a quote

Learn About High vs. Low Frequency Inverters: Which

An inverter is a key component that converts DC power into AC power for household appliances and is commonly used in solar energy

Get a quote

Can I Run the Motor Higher than 50Hz by Using a VFD?

Running an AC motor above its rated frequency using a Variable Frequency Drive (VFD) is often technically possible, but it requires a thorough

Get a quote

6.4. Inverters: principle of operation and parameters

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the

Get a quote

Understanding inverter frequency – effects and adjustments

In this comprehensive guide, we delve into the intricacies of inverter frequency, exploring its significance, factors affecting it, and its practical implications.

Get a quote

3000W pure sine wave inverter | 12 volt 3000 watt power inverter

3000W 12V Pure Sine Wave High Frequency Inverter Charger The only compact and minimal noise high frequency split phase inverter charger. Please Note: 240VAC output is available

Get a quote

Nine‐level high‐frequency inverter

In the high-frequency AC (HFAC) power distribution system, problems such as high switching frequency, a complicated circuit configuration and difficult parameter design still exist

Get a quote

Mastering Inverter Switching Frequencies: A Comprehensive Guide

Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our comprehensive guide, your blueprint to

Get a quote

Frequency Inverter Basic: Introduction, Functions and

Function of Frequency Inverter Speed Regulation Function: Frequency inverters can change the speed of the motor by adjusting the

Get a quote

Mastering Inverter Switching Frequencies: A

Explore the intricate dance of inverter switching frequencies to optimize energy flow. Master the rhythms of power electronics with our

Get a quote

SN74LVC2T45: Frequency calculation

Really the best way to determine maximum frequency is to put the device in the conditions that you expect to be operating and test it yourself. Technically, you

Get a quote

Mastering These 16 Frequency Inverter Parameter

The typical maximum frequency for inverters is up to 60Hz, with some reaching 400Hz. High frequencies allow motors to operate at high

Get a quote

The highest frequency and basic frequency of the inverter

The maximum frequency is the maximum frequency that the inverter allows to output, expressed by fmax. Its specific meaning varies slightly depending on how the

Get a quote

SN74LVC2T45: Frequency calculation

Really the best way to determine maximum frequency is to put the device in the conditions that you expect to be operating and test it yourself. Technically, you can have a huge propagation

Get a quote

A High Frequency Inverter for Variable Load Operation

Inverters operating at high frequency (HF, 3-30MHz) are important to numerous industrial and commercial applications such as induction heating, plasma generation, and wireless power

Get a quote

High Frequency Inverter Technical Specifications Explained

High frequency inverter technology utilizes switching frequencies typically ranging from 20kHz to 100kHz significantly higher than traditional low frequency inverters that operate

Get a quote

Power Frequency Inverter vs High-Frequency Inverter

These inverters are mostly found in applications with high volume or weight needs, such as aerospace, mobile power supplies, electric vehicles, or other fields. Power Frequency

Get a quote

Surge vs. Efficiency: Choosing Between Low and High-Frequency Inverters

Line-Frequency vs. High-Frequency Inverters: A Technical Deep Dive for Engineers In the world of power electronics, the inverter is a cornerstone technology, responsible for the

Get a quote

A Review on the Recent Development of High

With the demand for the miniaturization and integration of wireless power transfer (WPT) systems, higher frequency is gradually becoming the

Get a quote

(PDF) Review on Silicon Carbide based High-Fundamental Frequency

The analysis identifies a research gap in the development of high -power inverters (greater than 1 MW) capable of operating above 1 kHz fundamental frequencies. The

Get a quote

6 FAQs about [Maximum operating frequency of high-frequency inverter]

What is the difference between low frequency and high frequency inverters?

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time.

What is a high frequency inverter?

The typical maximum frequency for inverters is up to 60Hz, with some reaching 400Hz. High frequencies allow motors to operate at high speeds, which can strain the bearings and rotors of standard motors beyond their rated speed, challenging their ability to withstand the centrifugal forces.

What is the maximum inverter frequency?

The maximum inverter frequency depends on its design specifications, with most commercial models offering a maximum frequency between 10 kilohertz to megahertz.

What is the basic frequency of an inverter?

The frequency corresponding to the maximum output voltage of the inverter is called the basic frequency; b. When the output voltage of the frequency converter is equal to the rated voltage, the minimum output frequency is called the basic frequency. The fundamental frequency is represented by fBA.

Does victron use a high frequency inverter?

Victron combines both inverters, which they call Hybrid HF or Combined high frequency and line frequency technologies. What frequency inverter does growatt use? Growatt uses a high-frequency inverter. Which one is best? Low or high frequency? The best inverter is the low-frequency inverter.

How do high frequency inverters produce a sine wave output?

To produce a sine wave output, high-frequency inverters are used. These inverters use the pulse-width modification method: switching currents at high frequency, and for variable periods of time. For example, very narrow (short) pulses simulate a low voltage situation, and wide (long pulses) simulate high voltage.

Guess what you want to know

-

What frequency does a high-frequency inverter require

What frequency does a high-frequency inverter require

-

High-frequency inverter voltage and frequency

High-frequency inverter voltage and frequency

-

What is the maximum wattage of a 48v industrial frequency inverter

What is the maximum wattage of a 48v industrial frequency inverter

-

The difference between high-frequency inverter and industrial frequency inverter

The difference between high-frequency inverter and industrial frequency inverter

-

Tuvalu 48v industrial frequency inverter

Tuvalu 48v industrial frequency inverter

-

Simple sinusoidal high frequency inverter design

Simple sinusoidal high frequency inverter design

-

Advantages and disadvantages of dual silicon high frequency inverter

Advantages and disadvantages of dual silicon high frequency inverter

-

Taipei No 3 38000v high frequency inverter

Taipei No 3 38000v high frequency inverter

-

Belgian power frequency inverter manufacturer

Belgian power frequency inverter manufacturer

-

Russian medium frequency inverter price

Russian medium frequency inverter price

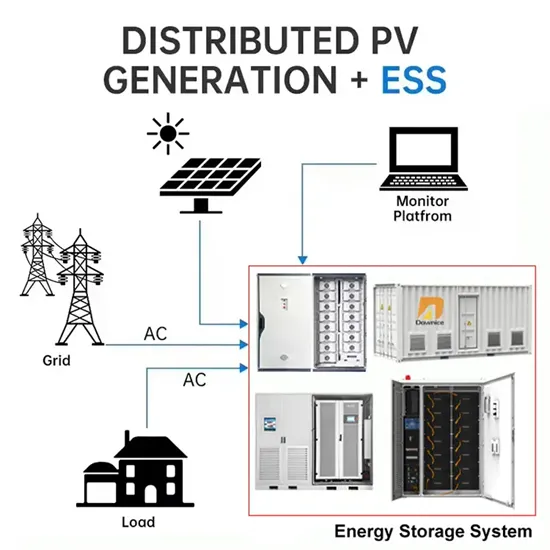

Industrial & Commercial Energy Storage Market Growth

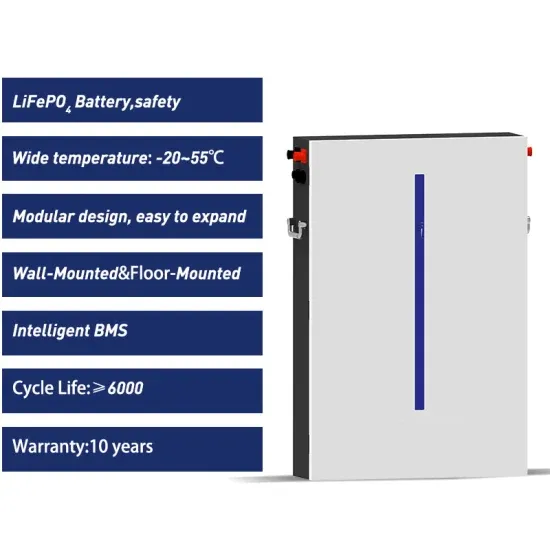

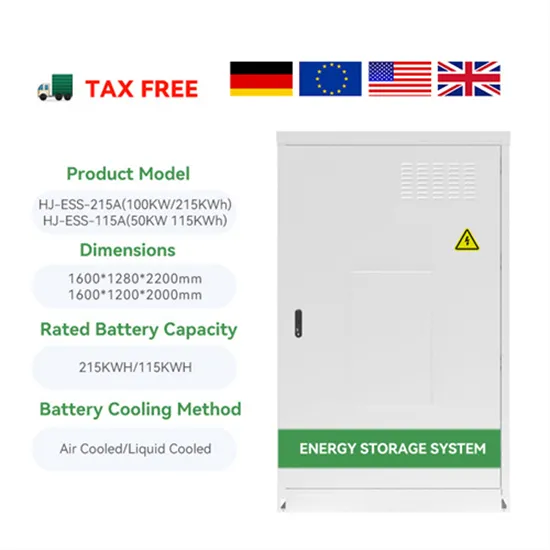

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.