Understanding Solar Panel Voltage: A Comprehensive Guide

The voltage output ranges from 228.67 volts to 466 volts per hour, depending on sunlight and climate conditions. How much voltage does a solar panel produce per day?

Get a quote

Understanding inverter voltage

A 12V to 240V inverter is a pivotal device designed to convert direct current (DC) power from a 12-volt battery into alternating current (AC) power with a nominal output of 240 volts.

Get a quote

Understanding Solar Panel Voltage for Better Output

When it comes to solar power, you need to understand the vital relationship between solar panel voltage, battery, and inverter. Solar panels

Get a quote

The Only Inverter Size Chart You''ll Ever Need

During our research, we discovered that most inverters range in size from 300 watts up to over 3000 watts. In this article, we guide you

Get a quote

Inverters 101: Understanding amps and volts

Note that on the 12-volt side of the inverter you need 1,200 watts going in, which works out to 100 amps x 12 volts = 1,200 watts. But on the 120

Get a quote

What Size Inverter Do I Need to Run a TV

How do I calculate what size inverter I need? Many people would be confused when shopping for the right inverter for their homes. If you want to know what size inverter you

Get a quote

How Many Amps Can a 3000-Watt Inverter Generator

The output ampere is typically 13A for a 3000-watt inverter in a 230V power system. This output can run 20-30 ceiling fans, 2-3 refrigerators, and 10

Get a quote

Inverter Specifications and Data Sheet

This value is the minimum DC voltage required for the inverter to turn on and begin operation. This is particularly important for solar applications because

Get a quote

A comprehensive guide to inverter voltage

Output voltage compatibility: Select an inverter that provides the output voltage required for your equipment. For residential applications, this is typically 120V AC (for North

Get a quote

What Will An Inverter Run & For How Long? (With

I saw on many forums that most people are confused about what they can run on their 1000,1500,2000,3000, & 5000-watt inverter and how long

Get a quote

A comprehensive guide to inverter voltage

Output voltage compatibility: Select an inverter that provides the output voltage required for your equipment. For residential applications, this is

Get a quote

300 watt Solar Panel: Output (Amps, volts), & What

300-watt Solar Panel How Many Amps and volts? 12v 300 watt solar panel will produce about 16.2 amps and 18.5 volts under ideal conditions

Get a quote

2000 Watt Amp: The Ultimate Guide to Power Inverters and Their

Discover everything you need to know about a 2000 watt amp — what it can run, how to choose the best power inverter 2000w, installation tips, troubleshooting, and more.

Get a quote

How To Size A Solar Inverter in 3 Easy Steps

The peak output of an inverter is typically over double its rated output power. Input voltage range is the minimum and maximum input voltage at which an inverter will function. If the voltage

Get a quote

The Only Inverter Size Chart You''ll Ever Need

During our research, we discovered that most inverters range in size from 300 watts up to over 3000 watts. In this article, we guide you through the different inverter sizes.

Get a quote

How many amps can an inverter put out?

1 amp at 120 volts is 10 amps at 12 volts. Same the other way around. Both = 120 watts. An inverter will need 160 amps at 12 volts to create 16 amps at 120 volts. Plus some

Get a quote

Understanding Inverter Input And Output: What Is The

Input Power Specification Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC source to the

Get a quote

PV Array Voltage and Size: What You Need to Know

Calculating your solar array voltage is critical if you''re designing your system yourself. This is because having too many panels in a series can exceed your inverter''s maximum input

Get a quote

Inverter Calculator

If not then you should purchase an inverter that has a pure sine wave or true sine wave output. If the power consumption is rated in amps, multiply the number of amps by 120 (AC voltage) to

Get a quote

How Many Batteries Are Needed For A 5000 Watt

Battery capacity for a 5000-watt inverter When using an inverter for power supply, selecting the right number of batteries is crucial as it determines

Get a quote

Understanding Inverter Input And Output: What Is The

Input Power Specification Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied

Get a quote

Inverter Specifications and Data Sheet

This value is the minimum DC voltage required for the inverter to turn on and begin operation. This is particularly important for solar applications because the solar module or modules must

Get a quote

Inverters 101: Understanding amps and volts

Note that on the 12-volt side of the inverter you need 1,200 watts going in, which works out to 100 amps x 12 volts = 1,200 watts. But on the 120-volt side of the inverter you get

Get a quote

Inverter Voltage Calculator, Formula, Inverter Voltage Calculation

Suppose an inverter has a DC input voltage of 600 volts and the output voltage is measured to be 450V. Calculate the modulation index. Given: V DC (V) = 600V, V (V) = 450V. Inverter voltage,

Get a quote

How many amps does a 1000-watt inverter draw?

An inverter is one of the most essential components of a solar system and before opting for an inverter you need to know the fundamental

Get a quote

6 FAQs about [How many volts does the inverter need to output ]

What is the output voltage of an inverter?

It describes the output voltage of an inverter, which converts direct current (DC) from sources like batteries or solar panels into alternating current (AC). The output voltage of an inverter is determined by the DC input voltage and the modulation index.

How many watts is a 12 volt inverter?

An inverter will need 160 amps at 12 volts to create 16 amps at 120 volts. Plus some loss in conversion. Volts times amps = watts. Watts are watts no matter what the volts or amps are. Your inverter will output 3300 watts for 5 seconds, most do have starting and operating ratings. If the breaker is a little weak that would trip it.

How do you calculate inverter voltage?

Understanding and calculating inverter voltage is crucial for ensuring the correct operation and efficiency of various electronic devices and systems. Inverter voltage, V (V) in volts equals the product of DC voltage, V DC (V) in volts and modulation index, dm. Inverter voltage, V (V) = V DC (V) * dm V (V) = inverter voltage in volts, V.

How many watts is a 120 volt inverter?

But on the 120-volt side of the inverter you get 1,200 watts coming out, which works out to 10 amps x 120 volts = 1,200 watts. It works out to an approximate 10:1 or 1:10 conversion factor depending if you’re converting from 12 volts to 120 volts, or 120 volts to 12 volts.

What do you need to know about input power inverters?

Here are some important specifications that you need to know about input power inverters. Input Voltage: The input voltage supplied from the DC source to the inverter follows the inverter voltage specifications, which start from 12V, 24V, or 48V.

How much power does an inverter need?

The continuous power requirement is actually 2250 but when sizing an inverter, you have to plan for the start up so the inverter can handle it. Third, you need to decide how long you want to run 2250 watts. Let’s say you would like to power these items for an eight-hour period.

Guess what you want to know

-

How many volts is the 220v output from the inverter relative to the ground

How many volts is the 220v output from the inverter relative to the ground

-

How many panels does a 15kw inverter in North Korea need at most

How many panels does a 15kw inverter in North Korea need at most

-

How big of an inverter do I need for 120kw

How big of an inverter do I need for 120kw

-

How big does the inverter need to be to convert 60v to 220v

How big does the inverter need to be to convert 60v to 220v

-

How big of an inverter do I need for a 48W

How big of an inverter do I need for a 48W

-

How many watts does a 48v inverter output

How many watts does a 48v inverter output

-

How many volts should I choose for lithium battery plus inverter

How many volts should I choose for lithium battery plus inverter

-

How many volts of overvoltage is a 24 volt inverter

How many volts of overvoltage is a 24 volt inverter

-

Inverter working output voltage is high

Inverter working output voltage is high

-

How to Consider Batteries When Connecting a Communication Base Station Inverter to the Grid

How to Consider Batteries When Connecting a Communication Base Station Inverter to the Grid

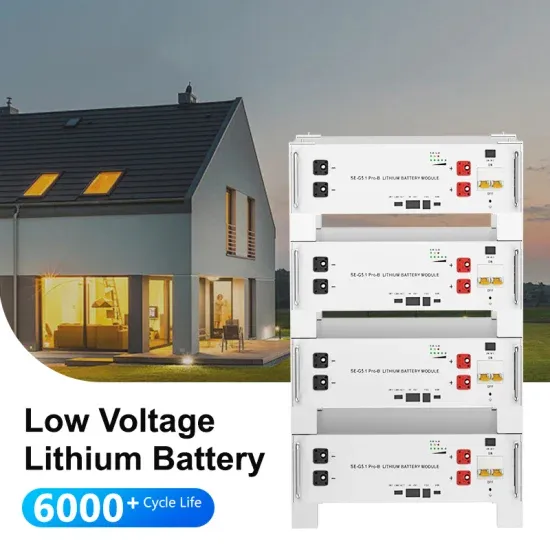

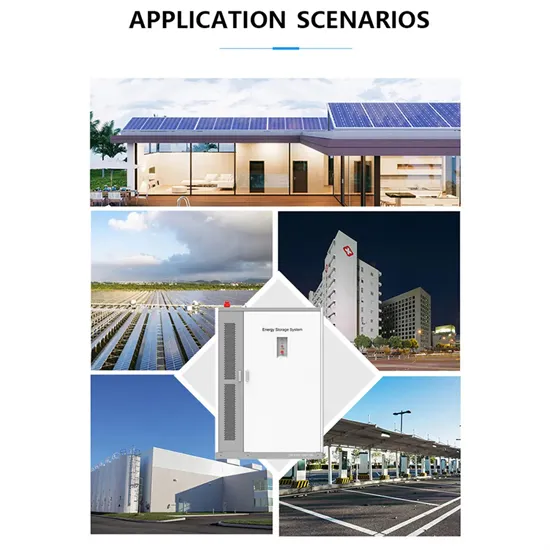

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

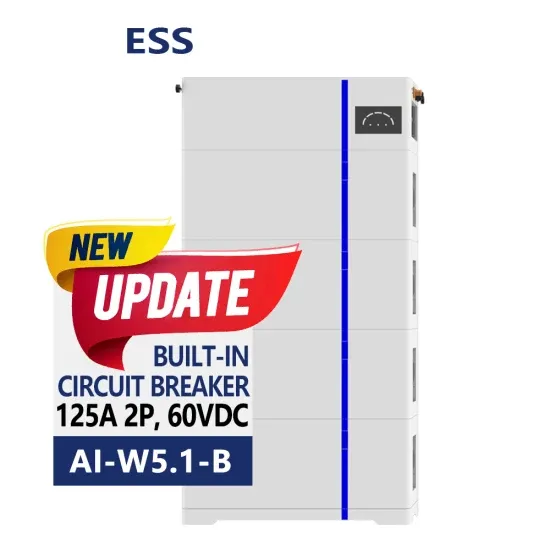

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.