How Many Amps Does an Inverter Draw?

Summary Understanding the current draw of an inverter at different powers is an important part of designing and selecting a power system. This article provides current

Get a quote

Understanding Inverter Input And Output: What Is The

The inverter output is the electrical power generated by the inverter from the process of converting the DC input source into alternating current (AC). The

Get a quote

MPPT charge controller calculator: Find the right solar

This max output current value is calculated by dividing the maximum system wattage (in Watts) by the minimum charging voltage of the

Get a quote

Battery Runtime Calculator: How Long Does Battery

How long will your battery last? find out with our easy-to-use battery runtime calculator.. (12v, 24v, 50ah, 150ah, 100ah, 200ah, 50ah)

Get a quote

Solar Panel Size Calculator

Use our solar panel size calculator to find out the ideal solar panel size to charge your lead acid or lithium battery of any capacity and voltage. For example, 50ah, 100ah,

Get a quote

Unlocking the Power: Understanding the Amps of a 5000-Watt Inverter

To calculate the amperage of a 5000 watt inverter, you need to know the voltage it operates at. If it operates at 120 volts, the amperage would be 41.67 amps (5000 watts ÷ 120

Get a quote

4000 WATT 48 VDC PURE SINE INVERTER

This inverter provides reliable power needed in any RV, boat, camping, business or residential emergency backup power application and built with a 48 Volt DC

Get a quote

How many amps does a 3000 watt inverter draw?

In general, a 3000 Watt inverter can draw as much as 350 Amps if it''s running on a 12V battery bank. If the 3000W inverter is running on a 24V

Get a quote

Inverter Calculator

Power consumption is rated either in wattage or amperes, and information regarding the required "watts" or "amps" generally is stamped or printed on most appliances and equipment. If this

Get a quote

Inverter Current Calculator

Inverter Current = 5000 ÷ 48 = 104.17 Amps. The current drawn is approximately 104.17 amps. Understanding how much current your inverter draws is vital for several reasons: Battery Bank

Get a quote

How many watts does 48v solar energy have | NenPower

The accumulated wattage across an extensive array of these panels could lead a solar energy system rated at 48 volts to output upwards of

Get a quote

How to Calculate Current Requirements for a 3000-Watt Inverter

How do you calculate the current draw from a 3000-watt inverter? To calculate the current draw from a 3000-watt inverter, follow these steps: Determine Voltage: Identify the

Get a quote

48V Inverter: The Ultimate Guide to Efficient and Scalable Power

If your peak usage is 3,000 watts, you''ll want a 48V inverter rated at least 20–25% higher to handle surge power comfortably—so something around 3,600–4,000 watts would be

Get a quote

Inverter Calculator

Power consumption is rated either in wattage or amperes, and information regarding the required "watts" or "amps" generally is stamped or printed on

Get a quote

How many watts does 48v solar energy have | NenPower

The accumulated wattage across an extensive array of these panels could lead a solar energy system rated at 48 volts to output upwards of 3000 watts in perfect settings.

Get a quote

Solar Power Basics for Beginners: Volts, Amps, Watts, Watt

Peak/surge power output - The max amount of watts the solar inverter can produce for a few seconds to support the high startup power some electronics like power tools need.

Get a quote

Calculating Battery Requirements for an 8000W Solar

A solar inverter is a magical device that converts the direct current (DC) produced by your solar panels into the alternating current (AC) that

Get a quote

How Many Amps Does a 100, 300, 500, 600, 750,

A 750 Watt Inverter typically pulls about 78.13 Amps. A 1000 Watt Inverter typically draws around 98 Amps. A 1500 Watt Inverter generally draws

Get a quote

How Do You Calculate the Appropriate Inverter Size for a 48V

To calculate the appropriate inverter size for a 48V battery system, you need to determine the total wattage of the devices you plan to power. The formula is: Inverter Size

Get a quote

4000 WATT 48 VDC PURE SINE INVERTER CHARGER

This inverter provides reliable power needed in any RV, boat, camping, business or residential emergency backup power application and built with a 48 Volt DC input for more efficiency.

Get a quote

The Differences Between 24v and 48v Inverter: Which is Better?

For the same amount of power, a 48V inverter outputs half the current of a 24V inverter. Lower current means less energy lost. Especially over long distances, 48V inverters

Get a quote

The Differences Between 24v and 48v Inverter: Which

For the same amount of power, a 48V inverter outputs half the current of a 24V inverter. Lower current means less energy lost. Especially

Get a quote

Inverter Amp Draw Calculator

It determines how many devices you can power and how long your inverter can function. In this article, let''s explore the inverter amp draw calculator for 1000W, 1200W, and

Get a quote

How many amps does a 3000 watt inverter draw?

In general, a 3000 Watt inverter can draw as much as 350 Amps if it''s running on a 12V battery bank. If the 3000W inverter is running on a 24V battery bank, it can draw up to

Get a quote

6 FAQs about [How many watts does a 48v inverter output ]

How many amps in a 48 volt inverter?

Now, maximum amp draw (in amps) = (1500 Watts ÷ Inverter’s Efficiency (%)) ÷ Lowest Battery Voltage (in Volts) = (1500 watts / 95% ) / 20 V = 78.9 amps. B. 100% Efficiency In this case, we will consider a 48 V battery bank, and the lowest battery voltage before cut-off is 40 volts. The maximum current is, = (1500 watts / 100% ) / 40 = 37.5 amps

How much current does a 3000 watt inverter draw?

If the 3000W inverter is running on a 24V battery bank, it can draw up to 175 Amps of current. If the battery bank is rated at 48V, the amp draw will not exceed 90 Amps. This is assuming the DC-to-AC conversion efficiency of the inverter (@ 3000 Watts) is around 85%.

How many amps does a 3000W inverter draw from a 12V battery?

If you’re working with kilowatts (kW), convert it to watts before calculation: Inverter Current = 1000 ÷ 12 = 83.33 Amps So, the inverter draws 83.33 amps from a 12V battery. Inverter Current = 3000 ÷ 24 = 125 Amps So, a 3000W inverter on a 24V system pulls 125 amps from the battery. Inverter Current = 5000 ÷ 48 = 104.17 Amps

How much current does an inverter draw?

The current drawn is approximately 104.17 amps. Understanding how much current your inverter draws is vital for several reasons: Battery Bank Sizing: Knowing the current helps determine how many batteries you need and how long they will last. Cable Sizing: Undersized cables can overheat or fail.

How many amps do inverters draw?

Inverters with a greater DC-to-AC conversion efficiency (90-95%) draw fewer amps, whereas inverters with a lower efficiency (70-80%) draw more current. Note: The results may vary due to various factors such as inverter models, efficiency, and power losses. Here is the table showing how many amps these inverters draw for 100% and 85 % efficiency.

What voltage does an inverter use?

Most residential and small commercial inverters use one of the following DC input voltages: As voltage increases, the current required for the same power decreases, making high-voltage systems more efficient for high-power applications. While calculating inverter current is straightforward, other factors may affect the actual current draw:

Guess what you want to know

-

How many watts does a 48v inverter use

How many watts does a 48v inverter use

-

How many watts can a 48v inverter produce

How many watts can a 48v inverter produce

-

How big an inverter can I use for 48v

How big an inverter can I use for 48v

-

How many watts does an 8-string lithium battery inverter in the UAE have

How many watts does an 8-string lithium battery inverter in the UAE have

-

How many watts does a Finnish 12v inverter 130 have

How many watts does a Finnish 12v inverter 130 have

-

How long does the high-voltage inverter continuously output

How long does the high-voltage inverter continuously output

-

How many volts is the 220v output from the inverter relative to the ground

How many volts is the 220v output from the inverter relative to the ground

-

How many watts of inverter should I use for 60A electricity

How many watts of inverter should I use for 60A electricity

-

18 How many watts of water pump inverter are suitable for solar panels

18 How many watts of water pump inverter are suitable for solar panels

-

How many watts does a 24v 220v inverter produce

How many watts does a 24v 220v inverter produce

Industrial & Commercial Energy Storage Market Growth

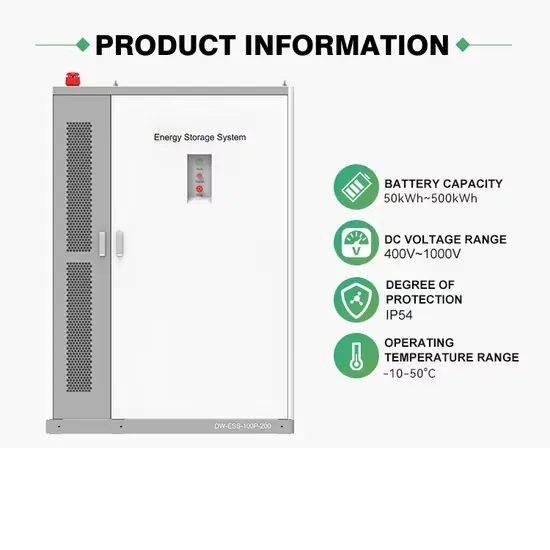

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.