Over voltage problem with Grid-tie micro inverter

Hi there. I have a 1200w no-name grid-tie micro inverter from Aliexpress (model GTB-1200). According to specs, it should handle 22-50v input, on each one of its 4 inputs. It

Get a quote

48V Inverter: The Ultimate Guide to Efficient and Scalable Power

48V Inverter vs 24 Volt DC Inverter: What''s the Difference? When it comes to choosing an inverter for your solar, backup, or off-grid power system, one of the first decisions

Get a quote

Inverter Going Over voltage

When using a soldering gun of only 180W, once the finger is off the trigger you see the voltage slowly climbing to 15.5V and then the inverter shuts off from over voltage alarm.

Get a quote

Inverter over voltage and shutdown

My 3kw generic 24 volt inverter shuts off when the SCC approaches full charge on the batteries. Usually the shut off only lasts 20 to 30 seconds and the inverter comes on again.

Get a quote

What voltage should 24 volt inverter shut off at?

1.75 volts per cell is the low voltage cut off point for all UPS battery systems. this is equal to 21 volts for a 24 volt system. Every system I have ever been involved with uses this

Get a quote

12V vs 24V Inverter: What''s the difference between 12

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the

Get a quote

Understanding inverter voltage

The Tycorun 3000w inverter boasts a rated input voltage of 12V, making it compatible with standard 12-volt battery systems. Its input voltage range is between 9.5

Get a quote

Frequently Asked Questions about Inverters

As a rule of thumb you should divide the connected capacity by 10 for 12 volt and by 20 for 24 volt. This also includes all the power losses in the cables, fuses and the inverter.

Get a quote

How Many Amps Does a 2000 Watt Inverter Draw?

The amp draw for a 2,000-watt inverter depends on factors such as the battery bank''s voltage rating and the unit''s conversion efficiency. But a

Get a quote

12V VS 24V Inverter: What are the Differences and How to Choose

In this article, we''ll explore the key differences between 12V and 24V inverters, helping you make an informed decision for your specific application.

Get a quote

12V VS 24V Inverter: What are the Differences and

In this article, we''ll explore the key differences between 12V and 24V inverters, helping you make an informed decision for your specific application.

Get a quote

Inverter Basics | inverter

While most inverters available in the market are either 12 or 24 volts, it''s worth noting that a higher voltage system is likely to offer greater efficiency. The 48 volt inverter,

Get a quote

12V vs 24V Inverters Key Differences and Which One is Right for

Inverters come in different voltage configurations, with 12V and 24V being the most common. The key difference between the two lies in the amount of power they can handle and

Get a quote

12V vs 24V Inverter: What''s The Difference & Which is Better

When choosing an inverter for your solar system, consider 12V for small setups, 24V for medium-sized systems, and 48 voltage inverter for large installations. Higher voltages offer better

Get a quote

Inverter overvoltage fault causes and treatment methods

If the inverter has no energy processing unit or its function is limited, the voltage of the intermediate DC circuit of the inverter will rise and exceed the protection value, and an

Get a quote

How many volts of overvoltage is a 24 volt inverter

At a certain voltage (often 21 volts on a 24 volt system), the inverter shuts down to protect itself from high currents. Full featured inverters have an adjustable LVD.

Get a quote

Grid Over Voltage Shuts Down Solar

Grid over voltage occurs when the voltage in the power lines your home or business is connected to exceeds the Australian standard, which is 230 volts plus 10% or minus 6% which gives the range of

Get a quote

12V vs 24V Inverter: What''s the difference between 12 and 24 Volt

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the electricity is converted from DC

Get a quote

Microsoft Word

Battery capacity is expressed by how many Amps for how many hours a battery will last - Amp-Hour (A.H.) capacity For a 12-Volt inverter system, each 100 Watts of the inverter load

Get a quote

24V battery amps

The amps halve as the voltage doubles. There is little consensus on this question but my rule is... 12 volts is ok for an inverter up to 2400 watts. 24 volts is ok for an inverter up

Get a quote

Exceeding voltage or amps on SCC | DIY Solar Power Forum

Over voltage jumps over the component ratings and the magic smoke is released. Five panels is a bit awkward. All in parallel or 2 parallel, 2 series is good. A 6th panel gives

Get a quote

Inverter Battery Voltage: How Many Volts Are Needed For

Using a 24-volt battery can also improve performance in systems that require higher voltage for optimal functioning, such as certain pumps or motors. Ultimately, select a 24

Get a quote

How Many Amps Does a 100, 300, 500, 600, 750,

If your inverter has a power of 750 watts, then you will need to see whether the voltage of your inverter is 12 volts, 14 volts, 24 volts, or 28 volts.

Get a quote

12V vs 24V Inverter: What''s the difference between 12 and 24 Volt

What''s the Difference Between a 12 and 24 Volt Inverter? The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery

Get a quote

Reduce Solar Panel Voltage (Volts + Calculations)

If you ask how to draw down the voltage in a solar panel that is not working, the answer is different but also easy. There are situations where you

Get a quote

6 FAQs about [How many volts of overvoltage is a 24 volt inverter ]

What is the difference between a 12V and 24V inverter?

The difference between a 12V and 24V inverter is the amount of input volts it can handle. This is the voltage flowing from the battery into the inverter before the electricity is converted from DC to AC. So a 12V inverter is designed for 12 volts input from the battery. And a 24V inverter is designed for 24 volts input from the battery.

Are 24V inverters good?

24V inverters offer better performance with more power intensive systems such as homes or larger appliances. Usually, 24V inverters are great for 1000 – 5000 watt inverters. You don’t need to go too much further into inverter voltage. All you really need to know is that you should always match the inverter and voltage battery.

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

What is the cut off voltage on a 12V inverter?

For a 12V inverter, the cut-off inverter voltage is often set around 9.5VDC. Dropping below this threshold triggers a shut-off mechanism to preserve the battery's health and longevity. How do you check the voltage on an inverter?

What is a 24V inverter?

24V Inverters: These systems generally offer higher efficiency, particularly in larger installations, thanks to lower current demands and reduced wire losses. This improved efficiency translates into energy savings, longer battery life, and potentially smaller system components.

Can a 12V inverter run on a 24v battery?

If you try to use a 12V inverter on a 24V battery it will be overloaded. Contrastingly, using a 24V inverter with a 12V battery will lead to a lack of electrical force. Knowing your inverter's voltage and what that means is critical in order for everything to run correctly.

Guess what you want to know

-

How big of an inverter should I use for a 24 volt

How big of an inverter should I use for a 24 volt

-

How many watts can a 48 volt inverter convert

How many watts can a 48 volt inverter convert

-

24 volt power inverter

24 volt power inverter

-

24 volt inverter 25 million

24 volt inverter 25 million

-

How many volts of battery can the inverter use

How many volts of battery can the inverter use

-

How many volts is the 220v output from the inverter relative to the ground

How many volts is the 220v output from the inverter relative to the ground

-

How much does a 12 volt inverter 220v cost

How much does a 12 volt inverter 220v cost

-

Inverter 24 volt inverter

Inverter 24 volt inverter

-

How many volts can the inverter convert to 220

How many volts can the inverter convert to 220

-

How big of an inverter should I use for a 12 volt system

How big of an inverter should I use for a 12 volt system

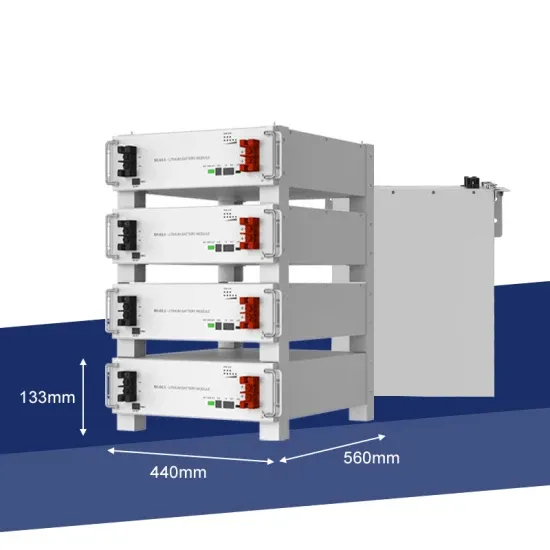

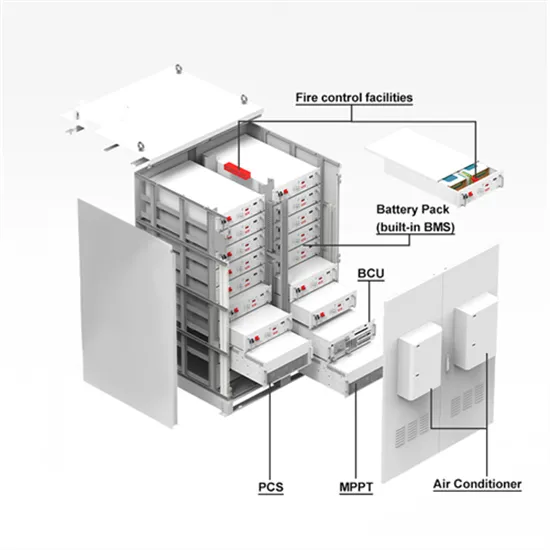

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.