Navigating Legal Compliance When Procuring Solar Panels from

When procuring solar panels from China, legal compliance is an essential component of securing a successful transaction and protecting your business interests. China

Get a quote

How much does it cost to buy solar panels for factories?

Solar panel costs can be classified into multiple avenues that all contribute to the final expenditure. Equipment costs, installation expenses, and maintenance fees stand out as

Get a quote

industrialization of solar panels | B2B companies and suppliers

Welcome to Europsunenergy, your leading provider of innovative and sustainable solar energy solutions in Europe. Our mission is to make the world a greener place through eco-friendly

Get a quote

Solar Procurement Solutions for the PV Sector | Targray

Our solar procurement solutions are a trusted source for PV manufacturers and project developers seeking to reduce costs through supply optimization.

Get a quote

Understanding Solar EPC: The Complete Guide to Engineering, Procurement

Solar EPC encompasses three distinct but interconnected stages: Engineering, Procurement, and Construction. Here''s a closer look at each component: The engineering

Get a quote

SunPower – Powering a Brighter Future | SunPower®

Imagine a home or business where solar panels capture energy, intelligent batteries store and manage electricity, and your entire property becomes a

Get a quote

Top 10 Solar Companies in Vietnam [Updated 2025]

Choosing where to purchase your first solar panel can be a daunting task, This is why we compiled a list of 10 solar companies in Vietnam to help!

Get a quote

Your Ultimate Guide to Sourcing Solar Pv Manufacturing

This guide offers a comprehensive overview of the solar PV manufacturing landscape, covering critical aspects such as types of solar panels, essential materials used in

Get a quote

Understanding the Solar EPC Process | EPC Solutions in India

If you''re planning to switch to solar in your manufacturing factory or industrial unit, you''ve probably come across the term EPC. It stands for Engineering, Procurement, and

Get a quote

How to Source Solar Panels Directly from Manufacturers in 2025

Reduce solar panel costs by purchasing directly from manufacturers. Explain global pricing trends, logistics solutions, warranty considerations and more for business buyers.

Get a quote

How to Import Solar Panels from China: A

This article provides a concise yet comprehensive guide on importing solar panels from China, detailing each key step from initial market

Get a quote

(PDF) Analyzing the lifecycle of solar panels including raw

The lifecycle of photovoltaic systems, encompassing the procurement of raw materials, manufacturing processes, and eventual disposal at the end of their operational

Get a quote

Mastering Solar Panel Procurement in China: The

Understanding Solar Panel Procurement in China: China''s solar panel market offers unparalleled opportunities for sourcing high-quality and

Get a quote

Understanding Solar EPC: The Complete Guide to

Solar EPC encompasses three distinct but interconnected stages: Engineering, Procurement, and Construction. Here''s a closer look at each

Get a quote

Solar Procurement Guide: Direct Manufacturers vs Distributors

Learn how solar procurement teams save 30-40% by choosing direct manufacturers over local distributors & avoid mid-contract price escalations

Get a quote

Solar Electric Supply – Leading Wholesale Solar Panels & Solar

Solar Electric Supply, Inc. (SES) is America''s oldest wholesale solar distributor and a premier provider of solar energy products. Founded with the vision of making solar power accessible

Get a quote

Understanding the Challenges with Pv Solar Panels in Global

The solar panel industry definitely faces some pretty big hurdles, especially when it comes to sourcing parts from all over the world. One tricky part is making sure the quality

Get a quote

A Detailed Guide To The Solar Project Development

Discover the solar project development process, uncover financing options, and gain valuable insights for a successful project in this comprehensive guide.

Get a quote

What Are the 9 Operating Costs of a Solar Panel Manufacturing

Discover the 9 key ongoing expenses for running a solar panel manufacturing plant. Get actionable insights to control costs and boost efficiency.

Get a quote

Sourcing solar panels in China: a guide

Unlock the power of solar energy with reliable Chinese solar panels! Discover quality suppliers, navigate technology choices, and ensure cost-effective procurement with

Get a quote

Understanding the Challenges with Pv Solar Panels in Global Procurement

The solar panel industry definitely faces some pretty big hurdles, especially when it comes to sourcing parts from all over the world. One tricky part is making sure the quality

Get a quote

6 FAQs about [Solar panel factory procurement]

How to manage the running costs in a solar panel manufacturing plant?

In a solar panel manufacturing plant like SolarTech Innovations, managing the running costs is crucial for maintaining a competitive edge. One of the key categories is overseeing the expenses related to equipment maintenance and repair schedules.

What makes a solar panel factory a good investment?

The backbone of any solar panel factory operating costs starts with the procurement of high-quality raw materials. In a facility like SolarTech Innovations, securing premium silicon, glass, and other components is essential as these materials can represent up to 40% of the total solar panel manufacturing costs.

How a solar panel manufacturing plant can reduce fuel and transportation costs?

Opt for energy-efficient logistics solutions to decrease fuel and transportation expenses. The energy consumption of a solar panel manufacturing plant is not just about powering machinery. It impacts the overall solar panel manufacturing costs significantly.

What is a solar procurement strategy?

Procurement includes purchasing solar panels, inverters, mounting structures, and electrical components. An effective procurement strategy prioritizes both quality and cost-effectiveness, ensuring that only reliable, high-performance equipment is used.

Do bulk purchase agreements reduce solar panel production costs?

Bulk purchase agreements for solar materials have been shown to lower solar panel raw material costs by as much as 20%, directly impacting the breakdown of solar panel production expenses favorably. Regular maintenance is essential to extend equipment lifespan and diminish equipment repair and downtime costs.

How to reduce solar panel manufacturing costs?

In a state-of-the-art facility like SolarTech Innovations, raw materials including high-purity silicon and specialty glass dominate the solar panel manufacturing costs. Bulk purchase agreements and strategic sourcing have proven to reduce these photovoltaic manufacturing expenses significantly.

Guess what you want to know

-

Go to the solar panel factory

Go to the solar panel factory

-

New Energy Solar Panel Factory

New Energy Solar Panel Factory

-

Solar panel factory in Angola

Solar panel factory in Angola

-

Western European Photovoltaic Solar Panel Factory

Western European Photovoltaic Solar Panel Factory

-

Azerbaijan solar panel factory

Azerbaijan solar panel factory

-

Azerbaijan solar panel procurement

Azerbaijan solar panel procurement

-

Build a solar photovoltaic panel factory

Build a solar photovoltaic panel factory

-

Solar Panel Smart Factory

Solar Panel Smart Factory

-

Solar panel factory production equipment installation

Solar panel factory production equipment installation

-

Sri Lanka non-standard photovoltaic curtain wall solar panel assembly factory

Sri Lanka non-standard photovoltaic curtain wall solar panel assembly factory

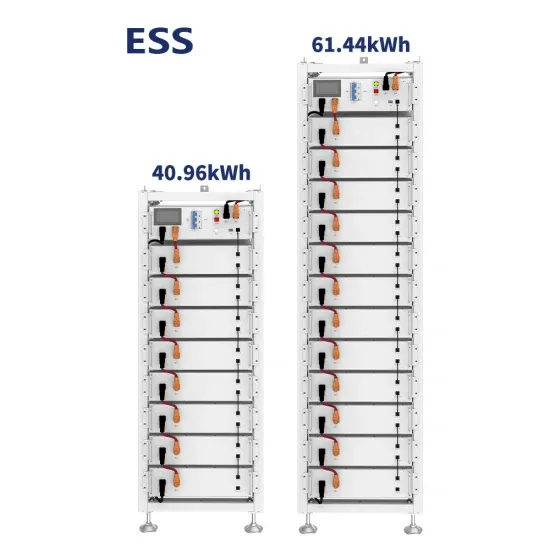

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

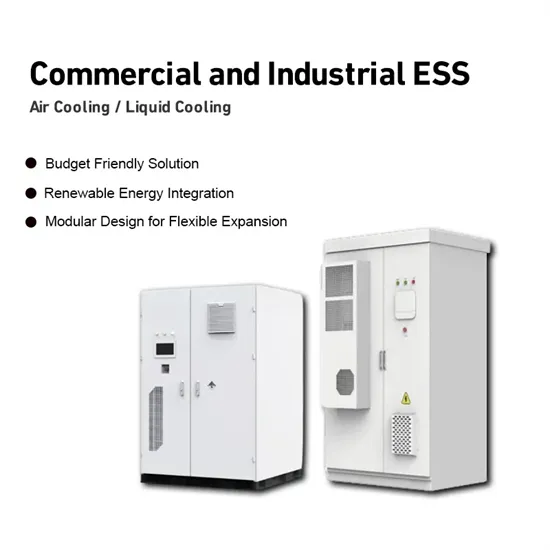

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.