RE+: Ten cutting-edge technologies from North America''s largest

3 days ago· New solar panels, battery energy storage systems, factory announcements and more are set to be unveiled at RE+ Las Vegas, Nevada, Sep 8-11.

Get a quote

SunPower – Powering a Brighter Future | SunPower®

Our Vision Imagine a home or business where solar panels capture energy, intelligent batteries store and manage electricity, and your entire property

Get a quote

5 Reasons Why Automation Improves Solar Energy

From silicon ingot formation to wafer slicing and cell assembly, nearly every stage of solar panel manufacturing relies heavily on automation

Get a quote

Hybrid Solar Systems Transform Industrial Automation: Power

Hybrid solar power systems are revolutionizing energy infrastructure by seamlessly integrating traditional photovoltaic panels with complementary power sources, transforming

Get a quote

Solar Panel Manufacturing Automation: How Smart

Industry 4.0 is revolutionizing solar panel manufacturing through intelligent automation, data analytics, and interconnected systems. The

Get a quote

Top 10 Solar Panel Manufacturers in China: Your

2. Trina Solar Headquarters: Wuxi, Jiangsu, China Key Factories: Changzhou (Jiangsu), Thailand, Vietnam Specialty: High-power modules for

Get a quote

Solar for Factory in Gujarat: Installation, Cost, and

Learn how to install solar panels for your factory in Gujarat. Get insights on pricing, system types, subsidies, and long-term savings.

Get a quote

RE+: Ten cutting-edge technologies from North America''s largest solar

3 days ago· New solar panels, battery energy storage systems, factory announcements and more are set to be unveiled at RE+ Las Vegas, Nevada, Sep 8-11.

Get a quote

Automation in Solar Panel Production: Transforming

Explore how automation is revolutionizing solar panel production, enhancing efficiency, reducing costs, and ensuring scalability in renewable energy

Get a quote

5 Reasons Why Automation Improves Solar Energy Manufacturing

From silicon ingot formation to wafer slicing and cell assembly, nearly every stage of solar panel manufacturing relies heavily on automation to achieve the precision, efficiency,

Get a quote

How Automation Transforms the Solar Panel Manufacturing Process

Industry trends show a steady move toward smart factories that use automated systems to speed up assembly and testing processes. As nations set ambitious global energy

Get a quote

Solar Panel Manufacturing Automation: How Smart Factories Are

Industry 4.0 is revolutionizing solar panel manufacturing through intelligent automation, data analytics, and interconnected systems. The integration of smart

Get a quote

2025 Smart Ecological Factory Building Project Solar Goods

Bid for tender to 2025 Smart Ecological Factory Building Project Solar Goods Techno Electronics 2 by Techno Electronics 2nd Plant Co., Ltd. in Korea. Access documents, deadlines, and CPV

Get a quote

10 Top Solar Panel Manufacturers Worldwide

Which are the top 10 solar panel manufacturers worldwide for 2025? Find out who is producing the most solar panels: China, India, or the USA?

Get a quote

Automation in Solar Panel Production: Transforming the Future

Explore how automation is revolutionizing solar panel production, enhancing efficiency, reducing costs, and ensuring scalability in renewable energy manufacturing.

Get a quote

Best 7 Solar Panel Manufacturers in Turkey : 2024 Guide

The production and utilization of solar energy in Turkey has been increasingly gaining momentum in recent years. Not only does the country have the ideal

Get a quote

9 Smart Manufacturing Examples of Industry 4.0

For example, the smart factory features solar panels on the rooftop (see also: questions to ask a solar company), encouraging a more sustainable

Get a quote

Engineer Overseeing Solar Panels Smart Factory Equipment

Buy Engineer Overseeing Solar Panels Smart Factory Equipment by DC_Studio on VideoHive. Industry 4.0 photovoltaics plant engineer overseeing using software on tablet to

Get a quote

Bulgaria gives green light to solar cell, panel factory

The Bulgarian government has approved a memorandum of understanding with Turkey''s Smart Solar Technologies AD for the construction of a solar cell and panel factory in

Get a quote

First Solar announces fifth U.S. factory as Inflation

First Solar, the nation''s largest solar panel manufacturer, announced Thursday that it will build its fifth U.S. factory as the Inflation

Get a quote

What Are the Innovations in Solar Factory Design? Discover the

Discover the latest innovations in solar factory design, from AI-driven automation and modular layouts to energy-efficient buildings and smart energy management.

Get a quote

Smart Integration of Industrial Solar Plants with AI & Tracking

The blog examines how smart technologies transform industrial solar power plants by improving their energy-management systems and operational performance. IoT devices

Get a quote

Solar Power Factory: Clean Energy Production

Build or supply a solar power factory with panels, inverters, and storage systems. Harness renewable energy for industrial or commercial scale generation.

Get a quote

What Are Smart Solar Panels? Learn How They Work & Why

Discover how smart solar panels optimize energy using AI, IoT, and real-time monitoring. Learn the benefits, challenges, and future trends.

Get a quote

Bila Solar''s Indiana Factory Commences Production

Behind-the-scenes video captures this milestone for American solar — creating local jobs and reinforcing why federal support for clean

Get a quote

Solar for Industries How Large-Scale Solar Power is Reshaping

At Sunbond, we are leading the solar revolution for industries, offering high-efficiency solar panels, smart energy management systems, and battery storage solutions that enable large

Get a quote

$1.4 BILLION INVESTMENT FROM KALYON SOLAR TECHNOLOGİES FACTORY

Established with an investment of $400 million, the factory will perform fully domestic solar panel production from A to Z. It will produce for Konya Karapınar Solar Power Plant in the first phase

Get a quote

6 FAQs about [Solar Panel Smart Factory]

What is a smart solar panel system?

Smart Safety – This smart solar panel system monitors weather conditions and takes that information into account when deciding when it should be open and when it should fold together for protection. Smart System – Think of the Smartflower as just another internet-connected device.

How automation is transforming the solar energy industry?

In the rapidly evolving solar energy sector, automation in solar panel production is emerging as a cornerstone of modern manufacturing processes. By integrating advanced technologies like AI, robotics, and IoT, companies such as Rayzon Solar are redefining how solar panels are designed, assembled, and distributed.

What is automation in solar panel production?

Automation in solar panel production involves leveraging technologies such as robotics, machine learning, and smart sensors to optimize the entire manufacturing process. From silicon wafer slicing to module assembly, these technologies minimize human intervention while maximizing accuracy and speed.

Why do we need automated solar panel manufacturing practices?

With demand for renewable energy surging, the need for modern solar panel manufacturing practices has never been greater. Automated processes are addressing challenges like labour shortages, cost efficiency, and product consistency, making solar panels more accessible and reliable than ever.

How can AI improve solar panel production?

AI in Solar Panel Production: AI algorithms analyze vast amounts of data to identify inefficiencies, predict potential equipment failures, and suggest process improvements. For instance, AI can optimize energy consumption in smart solar factories.

Why is robotic assembly important in solar panel production?

1. Robotic Assembly in Solar Panel Production: Robotic systems handle intricate processes such as cell placement and soldering, ensuring uniformity and reducing errors. These systems are crucial in modern solar factories, where high throughput is essential.

Guess what you want to know

-

American solar panel photovoltaic factory

American solar panel photovoltaic factory

-

Czech solar panel factory

Czech solar panel factory

-

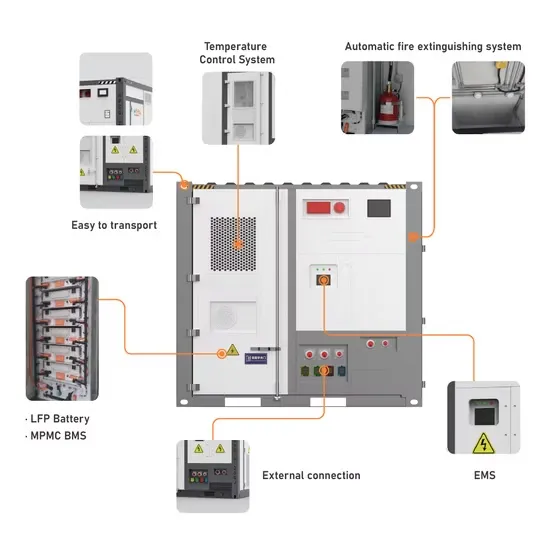

Solar Energy Storage Cabinet Smart Interconnected Factory

Solar Energy Storage Cabinet Smart Interconnected Factory

-

Azerbaijan solar panel factory

Azerbaijan solar panel factory

-

Bahrain Solar Photovoltaic Panel Customization Factory

Bahrain Solar Photovoltaic Panel Customization Factory

-

Portugal Customized Solar Panel Factory

Portugal Customized Solar Panel Factory

-

Algeria Solar Photovoltaic Panel Assembly Factory

Algeria Solar Photovoltaic Panel Assembly Factory

-

Solar thermal equipment for communication base station solar panel factory

Solar thermal equipment for communication base station solar panel factory

-

Mexico Transparent Series Photovoltaic Solar Panel Factory

Mexico Transparent Series Photovoltaic Solar Panel Factory

-

Building a solar panel factory

Building a solar panel factory

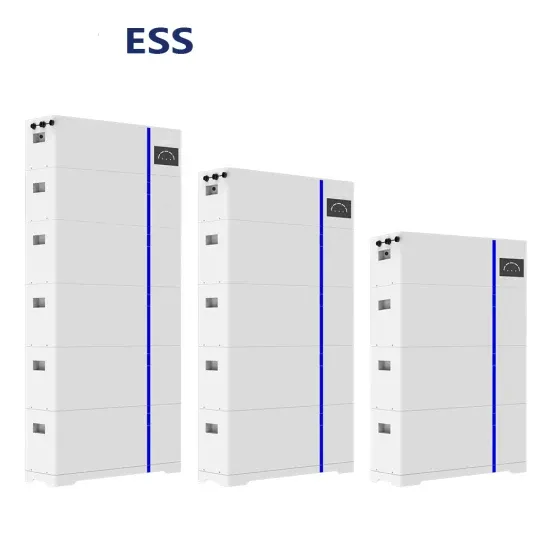

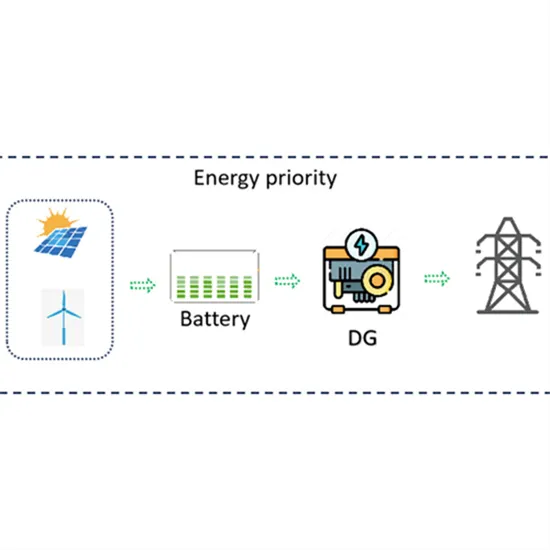

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.