solar panel grounding lugs manufacturers and suppliers | Sic-solar

We are China solar panel grounding lugs factory.Professional solar panel grounding lugs supplier,offer high quality solar panel grounding lugs at factory price! Inquiry now!

Get a quote

OMCO Solar plans Huntsville manufacturing facility

It is the nation''s premier manufacturer of solar trackers — devices that direct panels towards the sun — and fixed-tilt structures for solar arrays.

Get a quote

Qcells North America Completes Dalton Factory Expansion

[ATLANTA, Oct. 18, 2023] – Qcells, an industry-leading clean energy solutions provider, today announced the successful completion of its Dalton, Georgia, factory expansion. Qcells added

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get a quote

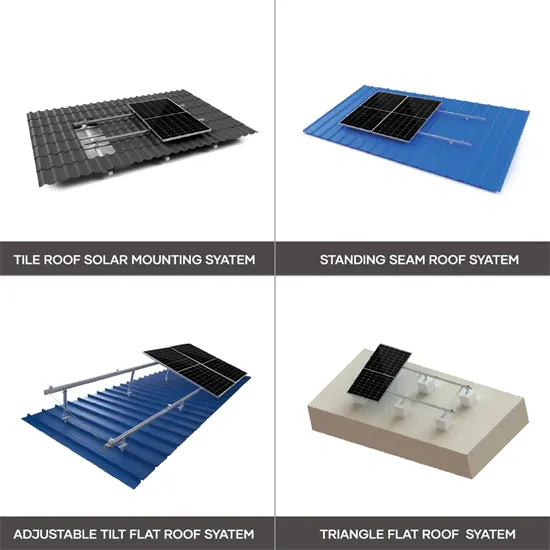

How to install solar panels and photovoltaic panels on

1. INTRODUCTION TO SOLAR PANEL INSTALLATION Installing solar panels and photovoltaic panels on a factory rooftop involves several

Get a quote

Rooftop Solar Panels For Commercial Buildings

Boost your business''s resilience with rooftop solar panels for commercial buildings and factories. Save on costs while going green. Discover

Get a quote

How to Start a Solar Panel Manufacturing Plant: Complete Guide

Solar Panel Manufacturing Plant Complete Guide: Discover everything you need to know about starting a solar panel manufacturing plant, from essential steps to industry trends.

Get a quote

How to start a solar panel manufacturing facility in the

Smaller Made-in-USA brands like Lumos Solar and CertainTeed Solar manufacture panels through an OEM in California. Others are choosing

Get a quote

This is how solar panels are made in a factory

With that done, the next step is to prepare and organize the solar cells. These can either be bought into the factory ready-made or built-in situ

Get a quote

Top 10 best solar panels manufacturers in China

For those who are finding China solar panels manufacturers, factories or supplies. You can contact them by go to their official website. And the top 5 solar panels China companies are

Get a quote

How to Start a Solar Panel Manufacturing Plant: Complete Guide

Solar Panel Manufacturing Plant Complete Guide is your go-to resource for diving into the world of solar panel production. This guide will take you through every aspect of setting up and

Get a quote

Solar Panel Factory Production Video

If you''ve ever wondered what goes into the actual making of a solar panel, this video walks through a Chinese panel factory. No annoying soundtrack, no voice over, just

Get a quote

Qcells North America Completes Dalton Factory

[ATLANTA, Oct. 18, 2023] – Qcells, an industry-leading clean energy solutions provider, today announced the successful completion of its Dalton, Georgia,

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get a quote

Mali solar panel factory: 200 MW Breakthrough Boosts Economy

3 days ago· Mali Solar Panel Factory: A National Milestone Mali has taken a major step towards renewable energy independence by launching its first fully nationally owned solar panel

Get a quote

How to start a solar panel manufacturing facility in the United States

Smaller Made-in-USA brands like Lumos Solar and CertainTeed Solar manufacture panels through an OEM in California. Others are choosing to go it alone in new plants.

Get a quote

Invenergy | Innovators in renewable and clean energy

PATASKALA, OH – June 4, 2024 - Illuminate USA, a leading US solar panel manufacturer, has shipped its very first panels to a new solar energy center under construction in Hardin County,

Get a quote

A new era of manufacturing: Pataskala''s Illuminate

The first solar panels rolled off the line Thursday as Illuminate USA began production at its 1.1-million-square-foot factory in Pataskala, which will

Get a quote

Inside the Qcells Factory: How Your Solar Panels Are Made

As a Factory-Direct Representative of Qcells, we at US Power get a unique, behind-the-scenes look at how these panels are made. And because of our direct relationship, your panels come

Get a quote

Factory 12v fridge and factory solar panel

My Brother in Law just picked up a 2022 XLS17MKE yesterday with a 12 v Fridge and he said it has a factory installed 2''-3'' solar array on the roof. He''s new to travel trailers and

Get a quote

This is how solar panels are made in a factory

With that done, the next step is to prepare and organize the solar cells. These can either be bought into the factory ready-made or built-in situ on the factory floor. Whichever the

Get a quote

6 FAQs about [Go to the solar panel factory]

What is a solar panel manufacturing plant Complete Guide?

Solar Panel Manufacturing Plant Complete Guide is your go-to resource for diving into the world of solar panel production. This guide will take you through every aspect of setting up and operating a solar panel manufacturing plant, ensuring you have the knowledge and tools to succeed in this booming industry.

How do I start a solar panel manufacturing plant?

Establishing a solar panel manufacturing plant involves careful planning and execution. The first step is to create a comprehensive business plan that outlines your objectives, target market, and production capacity. This plan will serve as a roadmap for your operations and help secure financing. Next, selecting the right location is critical.

Where are solar panels manufactured?

Solar panels are manufactured in the USA by smaller brands like Lumos Solar and CertainTeed Solar through an OEM in California. Some companies are also building new manufacturing plants, such as SolarWorld's revamped plant in Hillsboro, Oregon, which will produce SunPower high-efficiency modules.

How do I find suppliers for solar manufacturing materials?

Researching industry directories, attending trade shows, and networking with other manufacturers can help you find reliable suppliers for your solar manufacturing needs. What are the common challenges in solar panel manufacturing?

How are solar panels made?

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into wafers, then assembled into solar cells and connected to form solar modules.

How many solar panels are made in Dalton?

The completed Dalton expansion created 510 additional solar factory jobs and will also assemble two new solar products: the Q.TRON G2 residential solar panel and a bifacial panel for the commercial and utility markets. Qcells’ Dalton factory will manufacture nearly 30,000 solar panels per day.

Guess what you want to know

-

Build a solar photovoltaic panel factory

Build a solar photovoltaic panel factory

-

Western European Photovoltaic Solar Panel Factory

Western European Photovoltaic Solar Panel Factory

-

Czech solar panel factory

Czech solar panel factory

-

Go to the solar panel factory

Go to the solar panel factory

-

Building a solar panel factory

Building a solar panel factory

-

Solar panel factory production equipment installation

Solar panel factory production equipment installation

-

Zambia Customized Solar Panel Factory

Zambia Customized Solar Panel Factory

-

Solar thermal equipment for communication base station solar panel factory

Solar thermal equipment for communication base station solar panel factory

-

Algeria Solar Photovoltaic Panel Assembly Factory

Algeria Solar Photovoltaic Panel Assembly Factory

-

Burundi to build solar panel factory

Burundi to build solar panel factory

Industrial & Commercial Energy Storage Market Growth

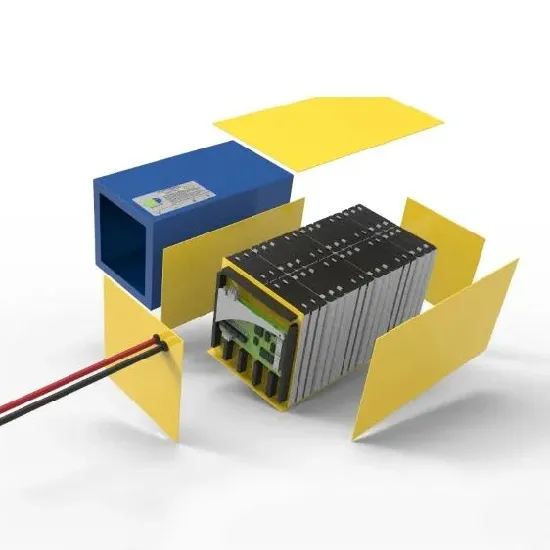

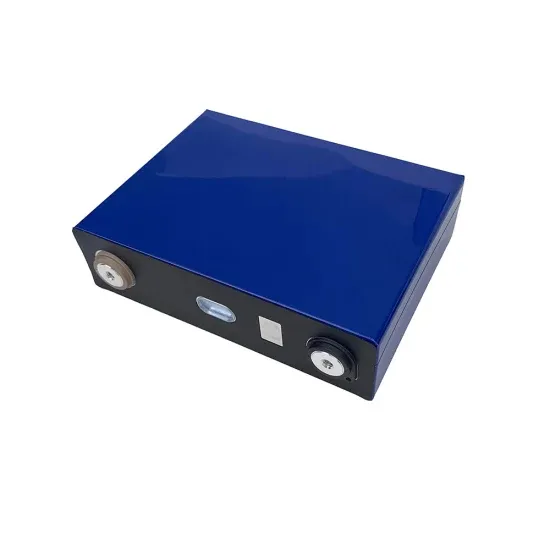

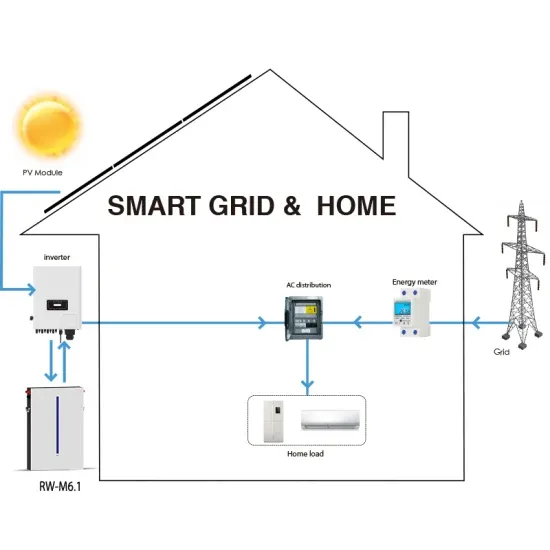

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.