How to Start a Solar Panel Manufacturing Plant in 9

Want to know how to start a solar panel manufacturing plant in 9 steps? Imagine launching a facility that not only contributes to sustainable

Get a quote

How to Build a Profitable Solar Panel Manufacturing Plant

This article explores all the information an entrepreneur needs to know in order to build a profitable Solar Panel Manufacturing. It covers everything from market demand, growth

Get a quote

ENEL ANNOUNCES INTENTIONS TO BUILD SOLAR PV CELL & PANEL

Enel North America intends to build one of the largest solar photovoltaic (PV) manufacturing facilities in the US, expected to initially produce at least 3 GW and scale up to 6

Get a quote

Solar Photovoltaic Projects

Photovoltaic (PV) solar electricity systems have captured a lot of interest as the system components have grown more mature, capable, and reliable. The references and articles

Get a quote

Solar Panel Manufacturing Process: Step-by-Step Guide

Complete solar panel manufacturing process – from raw materials to a fully functional solar panel. Learn how solar panels are made in a solar manufacturing plant,

Get a quote

HOW IT''S MADE: Solar Panels

HOW IT''S MADE: Solar Panels Solar panels are something that climate-conscious cities and towns have made almost abundant and popular! The energy from the sun is bountiful, and it makes sense that

Get a quote

How are solar panels manufactured? | Solar

We know solar panels as the futuristic-looking black or blue rectangles that soak up sunlight and bring down our energy bills. We might

Get a quote

How to build a solar photovoltaic panel factory | NenPower

Building a solar photovoltaic panel factory involves several critical steps to ensure success in the renewable energy sector. 1. Conduct comprehensive market re

Get a quote

Guide to launching a flexible solar panel factory

Establishing a flexible solar panel manufacturing plant is an exciting venture that aligns with the growing demand for renewable energy solutions. This guide outlines a detailed,

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on

Get a quote

How to Start a Solar Panel Manufacturing Plant in 9 Steps?

Want to know how to start a solar panel manufacturing plant in 9 steps? Imagine launching a facility that not only contributes to sustainable energy solutions but also taps into a

Get a quote

How to Start a Solar Panel Manufacturing Plant:

To put it simply, a solar panel manufacturing plant is a facility where photovoltaic cells are produced and assembled into solar panels. These panels convert

Get a quote

Setting Up a Solar PV Power Plant: A Step-by-Step

Unlock India''s solar potential with our definitive guide to establishing a solar PV power plant. Expert insights on photovoltaic

Get a quote

Solar Panel Manufacturing Cost: A Complete Factory Breakdown

Starting a solar panel factory? Get a detailed cost breakdown for machinery, buildings, and working capital for 25 MW, 100 MW, and 800 MW production lines.

Get a quote

Enel Announces PV Cell & Solar Panel Factory In The

Enel North America says it will build a solar panel and component factory in the United States with a capacity of 6 GW by 2025.

Get a quote

Tranos Begins Construction of Solar Panel Factory in Nigeria

Tranos has begun building an 800MW solar PV panel factory to localise renewable energy production in Nigeria. The new campus will house relocated factories, boost capacity,

Get a quote

Iberdrola and Exiom to build first large photovoltaic solar panels

The solar panel factory is expected to come into operation this year. It will have a capacity of 500 MW, incorporating state-of-the-art machinery for the production of solar

Get a quote

How to build a solar photovoltaic panel factory

Building a solar photovoltaic panel factory involves several critical steps to ensure success in the renewable energy sector. 1. Conduct

Get a quote

Italy''s Enel to build solar PV cell & panel factory in U.S

MILAN (Reuters) -Italian utility Enel said on Thursday it would build a solar photovoltaic (PV) cell and panel manufacturing facility in the United States in an effort to

Get a quote

Cost of Setting Up a Solar Panel Manufacturing Plant

Whether you''re at the beginning stages of planning or considering expanding an existing operation, this guide breaks down the key startup and ongoing costs you need to consider

Get a quote

Solar PV Panels For Factory And Warehouse Roofs

Solar photovoltaic (PV) panels for factory and warehouse rooftops are gaining popularity as industries in the UK seek sustainable and renewable energy

Get a quote

How to Start a Solar Panel Manufacturing Plant: Complete Guide

Solar Panel Manufacturing Plant Complete Guide: Discover everything you need to know about starting a solar panel manufacturing plant, from essential steps to industry trends.

Get a quote

how to start a solar panel factory?

Starting a solar panel factory is a significant undertaking that requires careful planning, sufficient funding, and the right expertise. The process can be complicated, but

Get a quote

Solar Photovoltaic Manufacturing Basics

Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background information on several manufacturing processes

Get a quote

6 FAQs about [Build a solar photovoltaic panel factory]

What is a solar panel manufacturing plant Complete Guide?

Solar Panel Manufacturing Plant Complete Guide is your go-to resource for diving into the world of solar panel production. This guide will take you through every aspect of setting up and operating a solar panel manufacturing plant, ensuring you have the knowledge and tools to succeed in this booming industry.

How do I start a solar panel manufacturing plant?

Establishing a solar panel manufacturing plant involves careful planning and execution. The first step is to create a comprehensive business plan that outlines your objectives, target market, and production capacity. This plan will serve as a roadmap for your operations and help secure financing. Next, selecting the right location is critical.

How does solar manufacturing work?

How Does Solar Work? Solar manufacturing encompasses the production of products and materials across the solar value chain. While some concentrating solar-thermal manufacturing exists, most solar manufacturing in the United States is related to photovoltaic (PV) systems.

How are solar panels made?

The key components in solar PV manufacturing include silicon wafers, solar cells, PV modules, and solar panels. Silicon is the primary material used, which is processed into wafers, then assembled into solar cells and connected to form solar modules.

How do I find suppliers for solar manufacturing materials?

Researching industry directories, attending trade shows, and networking with other manufacturers can help you find reliable suppliers for your solar manufacturing needs. What are the common challenges in solar panel manufacturing?

How long does it take to make solar panels?

The entire solar panel manufacturing process, from silicon wafer production to the final panel assembly, typically takes about 3-4 days. This includes cutting silicon wafers, assembling cells, encapsulating them, and quality testing before shipping.

Guess what you want to know

-

Argentina solar panel factory 1mw photovoltaic

Argentina solar panel factory 1mw photovoltaic

-

American solar panel photovoltaic factory

American solar panel photovoltaic factory

-

Bahrain Solar Photovoltaic Panel Customization Factory

Bahrain Solar Photovoltaic Panel Customization Factory

-

Sri Lanka non-standard photovoltaic curtain wall solar panel assembly factory

Sri Lanka non-standard photovoltaic curtain wall solar panel assembly factory

-

Is there a photovoltaic solar panel factory in Moldova

Is there a photovoltaic solar panel factory in Moldova

-

Sudan solar panel photovoltaic panel factory

Sudan solar panel photovoltaic panel factory

-

Solar thermal equipment for communication base station solar photovoltaic panel factory

Solar thermal equipment for communication base station solar photovoltaic panel factory

-

Algeria Solar Photovoltaic Panel Assembly Factory

Algeria Solar Photovoltaic Panel Assembly Factory

-

Brunei Photovoltaic Solar Panel Factory

Brunei Photovoltaic Solar Panel Factory

-

Venezuela solar photovoltaic panel factory

Venezuela solar photovoltaic panel factory

Industrial & Commercial Energy Storage Market Growth

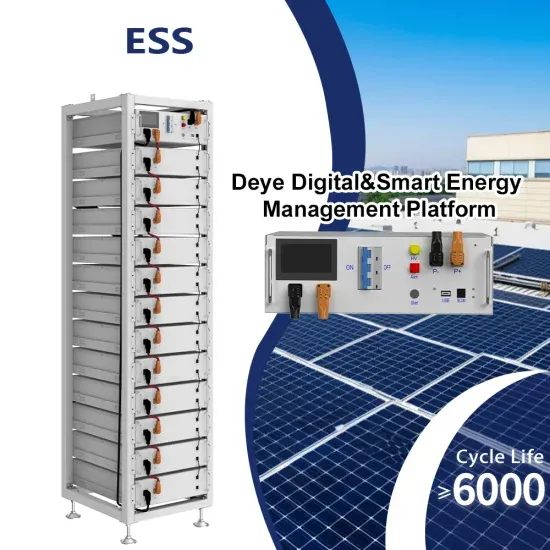

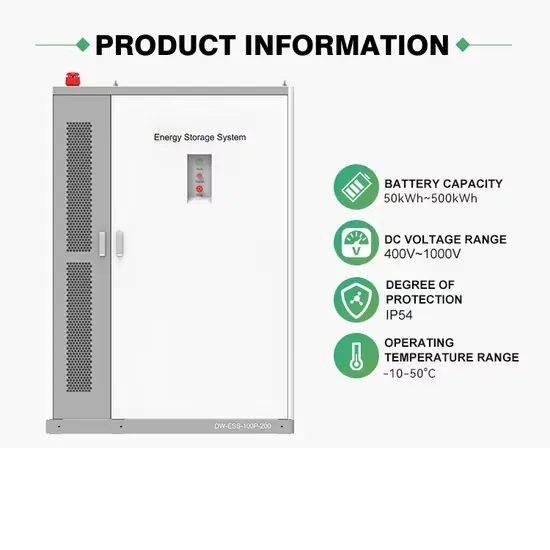

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.