IGBT FF1200R12IE5P: Loss calculation in an SPWM

Calculate loss in an SPWM voltage source converter topology Note: In conjunction with this article, you should refer to the following articles:

Get a quote

Inverter Current Calculator, Formula, Inverter Calculation

Inverter Current Calculator: Enter the values of inverter power, P i (W), input voltage, V i (V) and power factor, PF to determine the value of Inverter current, I (A).

Get a quote

Calculating Pure Sine Wave Inverter power draw

How much current is drawn from a 12V or 24V battery when running a battery inverter? Documented in this article are common questions relating to the inverter draw (inverter amp

Get a quote

Inverter Efficiency & Input Power Calculator | True Geometry''s Blog

Explanation Inverter Efficiency Overview: This calculator helps determine the efficiency of an inverter, which is the ratio of output power to input power, expressed as a

Get a quote

Inverter Capacity Calculator

Understanding inverter capacity is essential for ensuring that your backup power system can handle the electrical demands of all connected devices efficiently. This guide

Get a quote

Inverter Current Calculator

Click "Calculate" to find out the current the inverter will draw from the battery or DC power source. This calculated current is essential for battery selection, cable sizing, and protecting your

Get a quote

Full Load Current Calculator with Equations

The full load current calculator calculates the full load current for 1-phase AC, 3-phase AC and DC loads in kW, kVA or hp. Includes step-by-step equations.

Get a quote

Inverter Amp Draw Calculator

It determines how many devices you can power and how long your inverter can function. In this article, let''s explore the inverter amp draw calculator for 1000W, 1200W, and

Get a quote

Inverter Size Calculator

Learn how to calculate the required size of an inverter with our in-depth guide. We provide a handy formula, examples, and answers to common questions to help you make the right

Get a quote

Maximum Inverter Power Output Calculation | True Geometry''s Blog

Calculation Example: The maximum possible power output of an inverter is determined by multiplying the DC input voltage by the output current. This assumes 100%

Get a quote

Inverter DC Link Capacitor Selection

Properly sizing the DC link capacitor for a three phase inverter seems to be a skill that evades most power electronic engineers. The objective of this article is to help you better

Get a quote

Inverter Current Calculator & Formula Online Calculator Ultra

The inverter current calculation formula is a practical tool for understanding how much current an inverter will draw from its DC power source. The formula is given by:

Get a quote

Max Power Inverter Calculator | True Geometry''s Blog

Calculation Example: The maximum possible power output of an inverter is ideally the product of its DC input voltage and its output current. In reality, inverter efficiency will

Get a quote

Calculating Maximum Phase Currents for Three-Phase PWM Inverters

This calculator determines the maximum current flowing through each phase of a three-phase PWM inverter at full load. Calculation Example: The maximum current flowing

Get a quote

How Many Amps Does an Inverter Draw?

How Many Amps Does an Inverter Draw? An inverter is a device that converts direct current (DC) to alternating current (AC) and is widely used in areas such as solar power,

Get a quote

Inverter Size Calculator [Power Inverter, AC, DC,

The Inverter Size Calculator helps determine the appropriate inverter size for your power needs, whether for home appliances, solar

Get a quote

Calculating Maximum Phase Currents for Three-Phase PWM

This calculator determines the maximum current flowing through each phase of a three-phase PWM inverter at full load. Calculation Example: The maximum current flowing

Get a quote

How to Accurately Calculate the Current Draw for a 500W Inverter

To calculate current draw for a 500W inverter on a 12V system, use the formula: Current (A) = Power (W) / Voltage (V). Thus, Current = 500W / 12V = approximately 41.67A

Get a quote

Inverter Efficiency and Current Calculation | True Geometry''s Blog

Inverter Calculations This calculator provides the calculation of input current, output current, and efficiency of an inverter. Explanation Calculation Example: Inverters are

Get a quote

6 FAQs about [Inverter power calculation current]

How do you calculate dc current from an inverter?

To calculate the DC current draw from an inverter, use the following formula: Inverter Current = Power ÷ Voltage Where: If you’re working with kilowatts (kW), convert it to watts before calculation: Inverter Current = 1000 ÷ 12 = 83.33 Amps So, the inverter draws 83.33 amps from a 12V battery. Inverter Current = 3000 ÷ 24 = 125 Amps

What is inverter current?

Inverter current is the electric current drawn by an inverter to supply power to connected loads. The current depends on the power output required by the load, the input voltage to the inverter, and the power factor of the load. The inverter draws current from a DC source to produce AC power.

How do you calculate inverter power?

Using the same method as above, determine the variables required by the formula. For this example problem, these are: inverter power (watts) = 10 inverter voltage (volts) = 50 power factor = .4 Enter these given values into the calculator or above yields: I = 10/ (50* .4) = .5 (amps)

How much current does an inverter draw?

The current drawn is approximately 104.17 amps. Understanding how much current your inverter draws is vital for several reasons: Battery Bank Sizing: Knowing the current helps determine how many batteries you need and how long they will last. Cable Sizing: Undersized cables can overheat or fail.

What voltage does an inverter use?

Most residential and small commercial inverters use one of the following DC input voltages: As voltage increases, the current required for the same power decreases, making high-voltage systems more efficient for high-power applications. While calculating inverter current is straightforward, other factors may affect the actual current draw:

How to calculate inverter AMP draw?

In this article, let’s explore the inverter amp draw calculator for 1000W, 1200W, and 1500W. To calculate the amp draw for inverters at different voltages, you can use this formula Maximum Amp Draw (in Amps) = ( Watts ÷ Inverter’s Efficiency (%)) ÷ Lowest Battery Voltage (in Volts)

Guess what you want to know

-

High power and high current inverter production

High power and high current inverter production

-

Current power of inverter

Current power of inverter

-

What is the power of a 600w inverter

What is the power of a 600w inverter

-

Outdoor power inverter lithium and lead acid

Outdoor power inverter lithium and lead acid

-

Does inverter over-provisioning affect power

Does inverter over-provisioning affect power

-

Rated power 1 5kw inverter price

Rated power 1 5kw inverter price

-

24v inverter how much power protection to open

24v inverter how much power protection to open

-

Inverter actual power

Inverter actual power

-

Battery power frequency inverter

Battery power frequency inverter

-

Is it good to have multiple voltages for a power frequency inverter

Is it good to have multiple voltages for a power frequency inverter

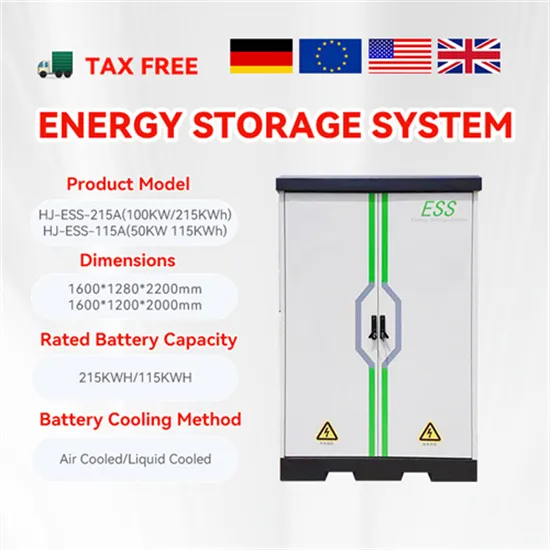

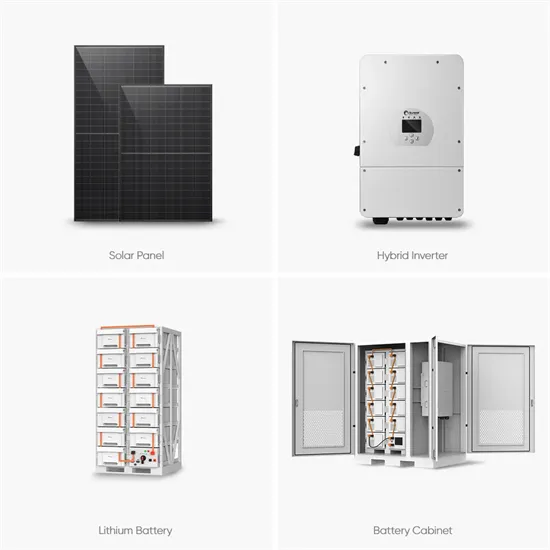

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.