Schaeffler Starts Volume Production of High-Voltage Inverter Brick

2 days ago· It is the first large-scale production of a high voltage inverter brick for leading Chinese automotive manufacturer.

Get a quote

Schaeffler chooses Rohm SiC MOSFETs for inverter brick

Companies start mass production of new high-voltage inverter brick intended for major Chinese car manufacturer Rohm and Schaeffler, a German automotive supplier, have

Get a quote

Schaeffler Begins Mass Production of High-Voltage Inverter Brick

5 days ago· Schaeffler has started volume production of its high-voltage inverter brick at its Tianjin site in China, supplying a leading domestic carmaker as part of its push to expand in

Get a quote

Next Generation Traction Inverter

The improved power device is a single switch package with dual-sided cooling. Uniquely, it ac-cepts various arrangements of different manufac-turers'' bare SiC dies on the same substrate.

Get a quote

PWM Current Source Inverters | part of High-Power Converters

This chapter focuses on the pulse‐width‐modulated (PWM) current source inverter (CSI) technologies for high‐power medium voltage drives. It analyses three modulation techniques

Get a quote

SiC MOSFETs adopted in inverter brick and now in mass production

6 days ago· The inverter brick is intended for a major Chinese car manufacturer. The Schaeffler inverter subassembly is the vital power device building block (brick) to control the electric drive

Get a quote

The Next Generation of High Power IGBT Modules

LV100 for Wind Converter, Photovoltaic Inverter and Motor Drives High power applications in the fields such as renewable energy and industrial drives require reliable and scalable power

Get a quote

Schaeffler chooses Rohm SiC MOSFETs for inverter brick

Companies start mass production of new high-voltage inverter brick intended for major Chinese car manufacturer Rohm and Schaeffler, a German automotive supplier, have

Get a quote

ROHM and Schaeffler Launch Mass Production of SiC-Based High

The Schaeffler inverter subassembly functions as the fundamental power electronics brick that governs the electric drivetrain through logic-based control signals. ROHM

Get a quote

Considerations on the Development of High-Power Density Inverters

In transportation electrification, power modules are considered the best choice for power switches to build a high-power inverter. Recently, several studies have presented

Get a quote

Review of very high frequency power converters and

With the increasing demand for volume reduction and efficiency improvement, very high frequency (VHF) power converters (30–300 MHz)

Get a quote

Current state of China''s photovoltaic inverter industry

This article will discuss current state of China''s PV inverter industry, including industrial chain structure, policy support, market size,

Get a quote

Measurement of the Conversion Efficiency of High

Evaluating the power conversion efficiency of high-voltage solar inverters requires current sensors and power analyzers capable of accommodating DC voltages

Get a quote

ROHM''s SiC MOSFETs Adopted in Schaeffler''s New Inverter

ROHM''s SiC MOSFETs Adopted in Schaeffler''s New Inverter Brick – Now in Mass Production Provided by GlobeNewswire Sep 4, 2025, 2:30:00 PM

Get a quote

ROHM and Schaeffler Launch Mass Production of SiC-Based

The Schaeffler inverter subassembly functions as the fundamental power electronics brick that governs the electric drivetrain through logic-based control signals. ROHM

Get a quote

Considerations on the Development of High-Power Density Inverters

This paper aims to compare the maximum output power and losses of inverters with different types (surface-mounted, through-hole-mounted and power modules) of

Get a quote

Inverter Technologies: Compare Off-Grid, On-Grid, and Hybrid

Inverter technology plays a critical role in modern solar power systems. It converts the direct current (DC) generated by solar panels into alternating current (AC) used by electrical devices.

Get a quote

Can someone explain the maximum DC power of this inverter?

As the "load" resistance is decreased, current will increase and dc array voltage will decrease. If you actually connect a 45kWp array then the inverter will never let the current get so high or

Get a quote

A Guide to Solar Inverters: How They Work & How to

What is a solar power inverter? How does it work? A solar inverter is really a converter, though the rules of physics say otherwise. A solar power inverter

Get a quote

Selecting the Right Power Supply for Hydrogen

With a full suite of reliable, high-performance products, we have the technology for any hydrogen production power supply challenge — from

Get a quote

Infineon high voltage Inverter Application Presentation

Advantage of Infineon Discrete IGBT (TO247-PLUS) Infineon''s industry-leading discrete IGBTs are compatible with Empower''s latest generation inverter in terms of packaging. Together with

Get a quote

ROHM and Schaeffler Begin Mass Production of SiC-Based High

ROHM and Schaeffler have started mass production of a new high-voltage inverter brick equipped with ROHM''s SiC (silicon carbide) MOSFET bare chips as part of their strategic

Get a quote

4 FAQs about [High power and high current inverter production]

What is a high efficiency power inverter?

High efficiency power inverters which use a modified sine wave to power 230V mains equipment from a 24V battery • Designed to work with most modern day lorries or marine power systems that run of a 24V alternator • Over 85% efficiency • Soft start minimise...

Who develops high voltage inverter systems for electric vehicles?

The vehicle manufactures and automotive tier 1 suppliers develop inverter systems for electric vehicles. Discussions were held with their design and research teams during direct meetings to understand future developments. Through these discussions, along with our own research, there are some clear high voltage inverter trends in the EV market. 3.

How can a high voltage inverter improve EV performance?

A better approach is to increase efficiency and decrease weight which extends the range of the EV and potentially reduces vehicle cost and running expenses. A significant contributor to achieving this is the inclusion of enhanced control, high voltage inverter modules in the vehicle. * Corresponding author.

What is the difference between SIC vs IGBT inverter?

Hybrid switch configuration considfred is 1:4 ratio (1 SiC + 3 IGBTs) Efficiency gain of full SiC Inverter and hybrid switch inverters vs IGBT inverter is from low load to medium load, generating advantages in power systems that operate most of the time below 40% load Hybrid switch inverter shows similar efficiency curve compared to SiC.

Guess what you want to know

-

High power 2kw inverter production

High power 2kw inverter production

-

High power inverter front stage

High power inverter front stage

-

Industrial frequency inverter high power solar energy

Industrial frequency inverter high power solar energy

-

French solar high power water pump inverter

French solar high power water pump inverter

-

Communication base station inverter high power

Communication base station inverter high power

-

Communication base station inverter equipment has high power consumption

Communication base station inverter equipment has high power consumption

-

Dc24v high current inverter

Dc24v high current inverter

-

300W inverter high power

300W inverter high power

-

How much power does a high voltage inverter have

How much power does a high voltage inverter have

-

3kw high power inverter

3kw high power inverter

Industrial & Commercial Energy Storage Market Growth

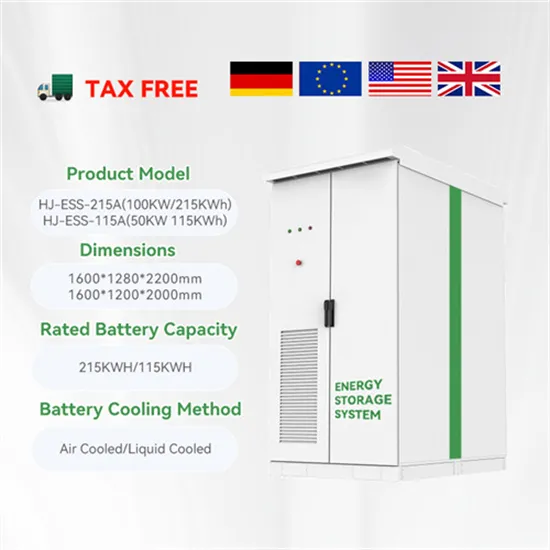

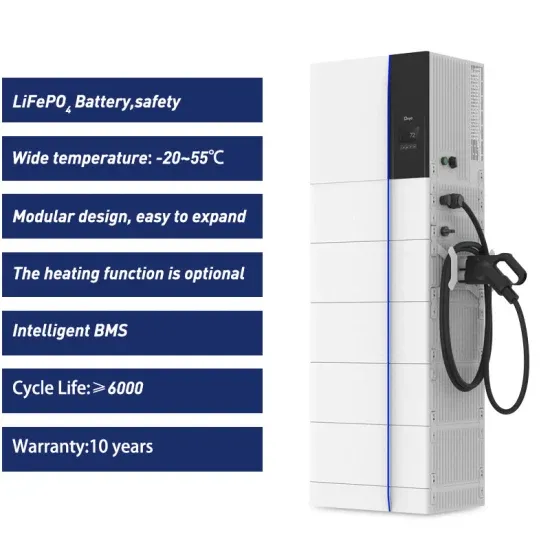

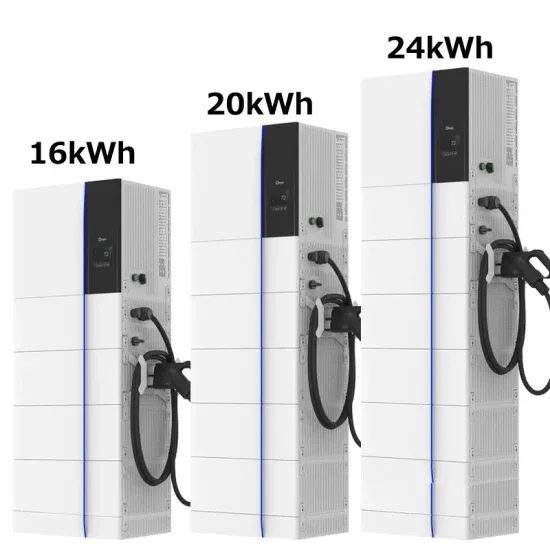

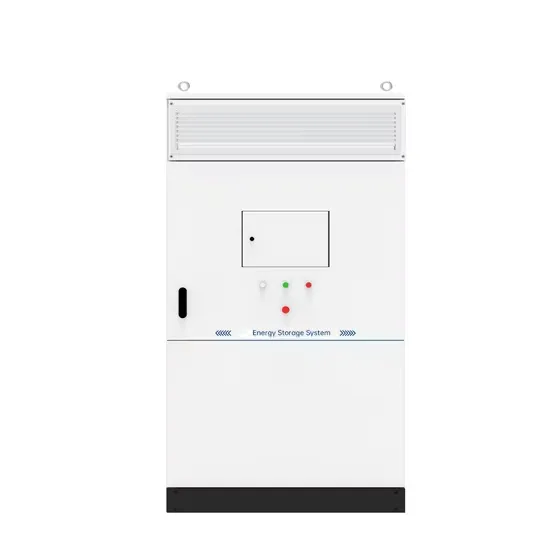

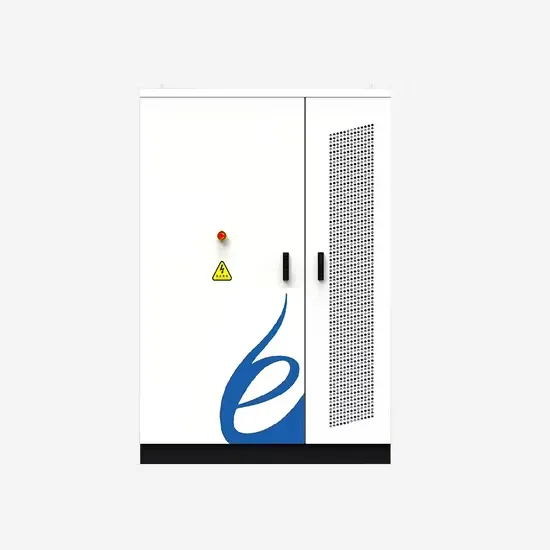

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.