Optimization of liquid cooled heat dissipation structure

Discussion: The proposed liquid cooling structure design can effectively manage and disperse the heat generated by the battery. This

Get a quote

What are the liquid-cooled energy storage power

Unlike solid-state batteries or conventional energy storage methods that rely heavily on solid materials, these innovative power stations

Get a quote

Liquid Cooling for Supermicro Servers

Many data center cooling solutions are required to maintain the optimal operating conditions for today''s data centers'' smooth and efficient operation. As AI and big data rise require massive

Get a quote

Liquid Cooling in Energy Storage: Innovative Power Solutions

This article explores the benefits and applications of liquid cooling in energy storage systems, highlighting why this technology is pivotal for the future of sustainable energy.

Get a quote

A review on the liquid cooling thermal management system of

The use of refrigerants can integrate battery cooling and cabin cooling systems, and the working medium is supplied from the liquid storage chamber branch to the battery cooling

Get a quote

Liquid Cooling System Energy Storage: Why It''s the Future of

That''s essentially what air cooling does for high-density energy storage systems. Liquid cooling systems, on the other hand, act like a precision ice bath—keeping temperatures

Get a quote

Phase change cooling in data centers: A review

In this paper, the up-to-date PCC technologies are reviewed and summarized, as well as the latest progress in DC cooling field. Four main PCC technologies are discussed in

Get a quote

Energy storage systems: a review

The world is rapidly adopting renewable energy alternatives at a remarkable rate to address the ever-increasing environmental crisis of CO2 emissions.

Get a quote

Liquid Cooling in Energy Storage | EB BLOG

Explore the evolution from air to liquid cooling in industrial and commercial energy storage. Discover the efficiency, safety, and performance benefits driving this technological shift.

Get a quote

Thermal Management for Energy Storage: Air or Liquid Cooling?

Choosing the right cooling technology for Battery Energy Storage Systems (BESS) is crucial for performance and longevity. Explore air vs. liquid cooling and discover

Get a quote

How Liquid Cooling Systems are Redefining Energy Storage

Conclusion Energy storage liquid cooling systems represent a transformative leap in solving the complex challenges of heat dissipation and safety in high-density energy storage

Get a quote

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

As a global leader in lithium-ion battery energy storage manufacturing, GSL ENERGY''s liquid-cooled energy storage system features advanced temperature control

Get a quote

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which Cooling

With larger systems and higher cycling demands, liquid cooling is rapidly becoming the mainstream choice for projects over 1MWh or 500kW. That said, air cooling still dominates

Get a quote

Liquid Cooling System Energy Storage: Why It''s the Future of Power

That''s essentially what air cooling does for high-density energy storage systems. Liquid cooling systems, on the other hand, act like a precision ice bath—keeping temperatures

Get a quote

What are the liquid-cooled energy storage power stations?

Unlike solid-state batteries or conventional energy storage methods that rely heavily on solid materials, these innovative power stations employ a liquid medium to store

Get a quote

All-in-One Liquid Cooling Energy Storage Systems | GSL BESS

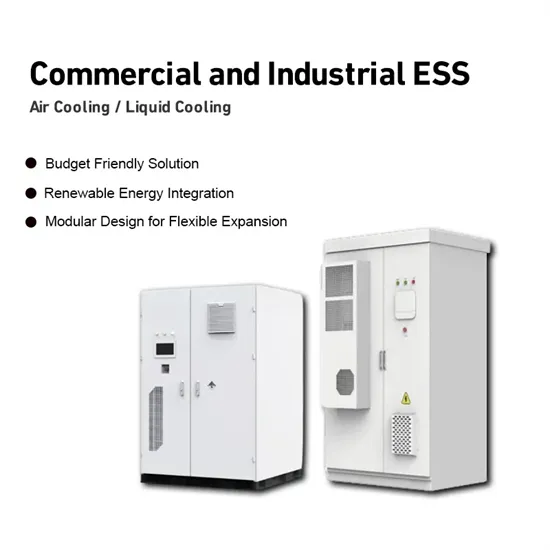

Discover GSL ENERGY''s high-capacity all-in-one liquid cooling energy storage systems from 208kWh to 418kWh. Designed for commercial and industrial ESS, with advanced thermal

Get a quote

All-in-One Liquid Cooling Energy Storage Systems

Discover GSL ENERGY''s high-capacity all-in-one liquid cooling energy storage systems from 208kWh to 418kWh. Designed for commercial and industrial

Get a quote

Energy storage cooling system

Compared with air-cooled systems, liquid cooling systems for electrochemical storage power plants have the following advantages: small footprint, high operating efficiency,

Get a quote

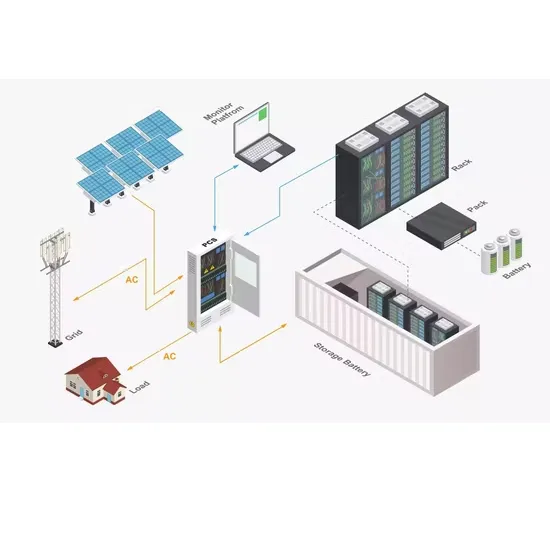

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring

Get a quote

High-uniformity liquid-cooling network designing approach for energy

In this work, an approach for rapid and efficient design of the liquid cooling system for the stations was proposed.

Get a quote

Keep It Cool with Thermal Energy Storage

In contrast, cool TES uses off-peak power to provide cooling capacity by extracting heat from a storage medium, such as ice, chilled water, or "phase-change materials." Typically, a cool

Get a quote

Liquid Cooling in Energy Storage | EB BLOG

Explore the evolution from air to liquid cooling in industrial and commercial energy storage. Discover the efficiency, safety, and performance

Get a quote

Battery Energy Storage Systems

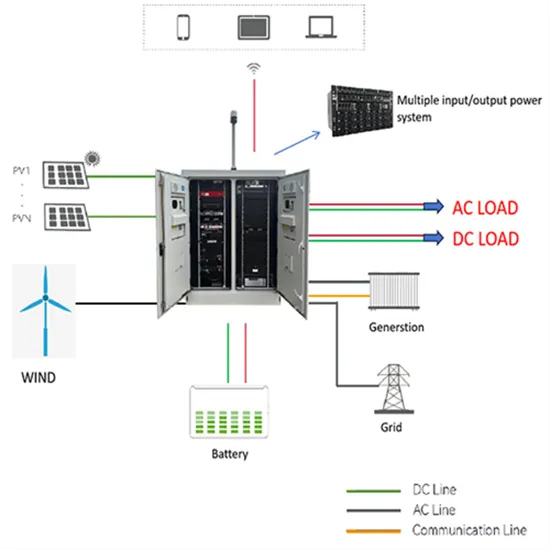

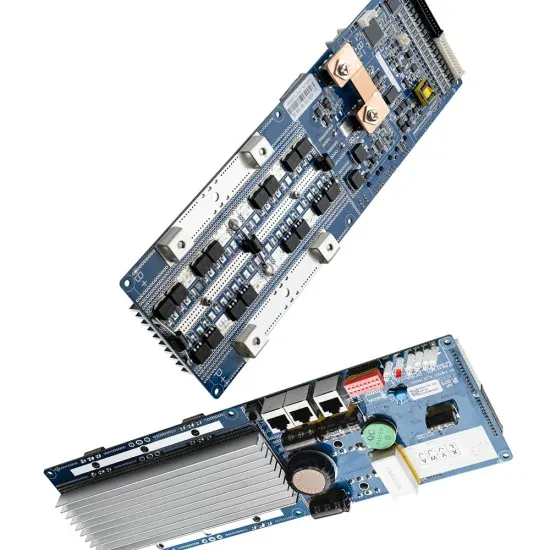

BATTERY STORAGE SYSTEM COMPONENTS Battery storage systems convert stored DC energy into AC power. It takes many components in order to maintain operating conditions for

Get a quote

1.2–2.4MWh Liquid-cooled ESS for Commercial & Industrial Energy Storage

Discover Battlink''s 1.2–2.4MWh liquid-cooled battery energy storage system, engineered for commercial and industrial applications. Maximize energy efficiency, reduce costs, and ensure

Get a quote

Air-Cooled vs. Liquid-Cooled Energy Storage Systems: Which

With larger systems and higher cycling demands, liquid cooling is rapidly becoming the mainstream choice for projects over 1MWh or 500kW. That said, air cooling still dominates

Get a quote

Why Choose a Liquid Cooling Energy Storage System? | GSL

As a global leader in lithium-ion battery energy storage manufacturing, GSL ENERGY''s liquid-cooled energy storage system features advanced temperature control

Get a quote

Liquid cooling design requirements for energy storage systems

Liquid cooling technology involves the use of a coolant, typically a liquid, to manage and dissipate heat generated by energy storage systems. This method is more efficient than traditional air

Get a quote

Grid-Scale Storage Gets Smarter with Liquid-Cooled Commercial

Smarter grid-scale storage solutions are now needed. Systems that have better energy density, stronger heat management, and longer life are in high demand. One new

Get a quote

Air Conditioning with Thermal Energy Storage

Abstract Air-Conditioning with Thermal Energy Storage Thermal Energy Storage (TES) for space cooling, also known as cool storage, chill storage, or cool thermal storage, is a cost saving

Get a quote

6 Low-temperature thermal energy storage

Sensible storage of heat and cooling uses a liquid or solid storage medium witht high heat capacity, for example, water or rock. Latent storage uses the phase change of a material to

Get a quote

6 FAQs about [Liquid cooling system for medium-sized energy storage power stations]

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

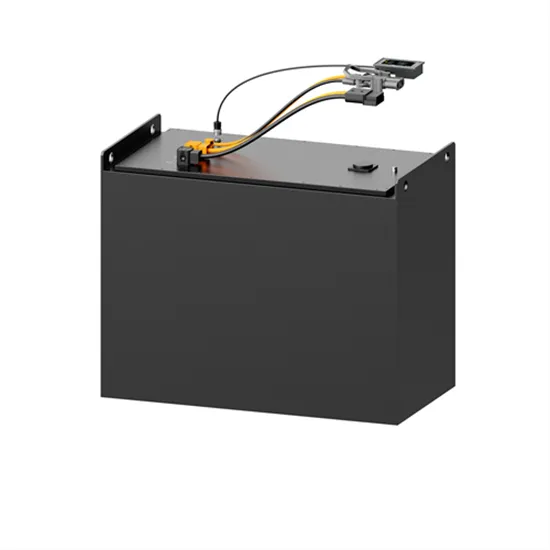

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

Guess what you want to know

-

Liquid cooling standards for energy storage power station buildings

Liquid cooling standards for energy storage power station buildings

-

Operation and management of liquid cooling system of energy storage power station

Operation and management of liquid cooling system of energy storage power station

-

Indonesian companies that make energy storage power stations

Indonesian companies that make energy storage power stations

-

Summarize the functions of energy storage power stations

Summarize the functions of energy storage power stations

-

Battery safety in energy storage power stations

Battery safety in energy storage power stations

-

Division of battery units in energy storage power stations

Division of battery units in energy storage power stations

-

Geological requirements for wind solar and energy storage power stations

Geological requirements for wind solar and energy storage power stations

-

Lithium iron phosphate and lead carbon in energy storage power stations

Lithium iron phosphate and lead carbon in energy storage power stations

-

Voltage adaptability of energy storage power stations

Voltage adaptability of energy storage power stations

-

The price of wind and solar energy storage power stations

The price of wind and solar energy storage power stations

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.