125KW/233KWh Liquid-Cooling Energy Storage Integrated

In order to ensure the safety of energy storage power stations, the selection and design of energy storage system equipment should follow the principles of "prevention first, prevention and

Get a quote

Data Center Basics: Building, Power, and Cooling

Data Center Basics: Building, Power, and Cooling Internet and cloud services run on a planet-scale computer with workloads distributed across mul-tiple data center buildings around the

Get a quote

Liquid cooling medium standard for energy storage power

Liquid-cooled energy storage power stations are advanced facilities designed to store energy in a liquid medium, often utilizing specialized systems to manage heat, optimize

Get a quote

Liquid Cooling System Design, Calculation, and Testing for Energy

Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal management, fire suppression, and testing validation

Get a quote

Liquid Cooling Solutions for Energy Storage Systems.

Our innovative liquid cooling solutions offer numerous advantages, including efi cient heat dissipation for longer battery life, even temperature distribution for optimal performance and

Get a quote

High-uniformity liquid-cooling network designing approach for

Our approach was devised to efficiently construct liquid-cooling networks specifically tailored for diverse scale BESSs, with considerations of cost-effectiveness, energy

Get a quote

How Can Liquid Cooling Revolutionize Battery Energy Storage

With the rapid advancement of technology and an increasing focus on energy efficiency, liquid cooling systems are becoming a game-changer across multiple industries. Among these,

Get a quote

Cooling technologies for data centres and telecommunication

Data centres (DCs) and telecommunication base stations (TBSs) are energy intensive with ∼40% of the energy consumption for cooling. Here, we provide a

Get a quote

Commercial & Industrial Liquid Cooling Energy Storage System

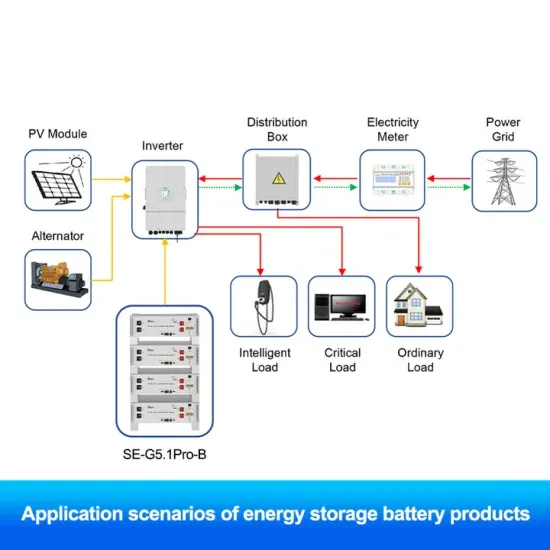

This system ensures efficient, safe, and long-lasting energy storage with liquid cooling technology, high-voltage lithium iron phosphate (LiFePO4) chemistry, and seamless grid integration.

Get a quote

Kehua S³ EStation Liquid-Cooling ESS Showcase:

Highly Reliable S³ EStation Liquid-Cooling ESS Ensures Safe Operation of the Power Station The total capacity of the power station is 200MW/400MW, with

Get a quote

Energy storage power station water cooling system

Small footprint--Geothermal power plants and geothermal heat pumps are compact. Geothermal power plants use less land per gigawatt-hour (404 m 2) than comparable-capacity coal (3,642

Get a quote

Liquid cooling design requirements for energy storage systems

While liquid cooling systems for energy storage equipment, especially lithium batteries, are relatively more complex compared to air cooling systems and require additional components

Get a quote

High-uniformity liquid-cooling network designing approach for energy

Our approach was devised to efficiently construct liquid-cooling networks specifically tailored for diverse scale BESSs, with considerations of cost-effectiveness, energy

Get a quote

What are the liquid-cooled energy storage power

In liquid-cooled energy storage systems, various liquids can be utilized depending on the specific design and operational requirements of the

Get a quote

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

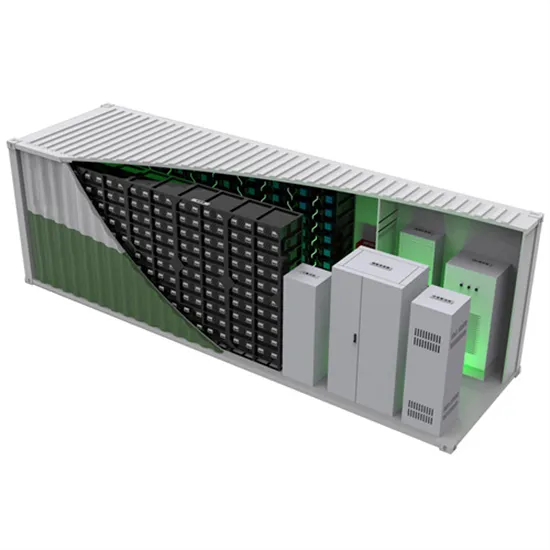

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20''GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring

Get a quote

Energy storage cooling system

Compared with air-cooled systems, liquid cooling systems for electrochemical storage power plants have the following advantages: small footprint, high operating efficiency,

Get a quote

Liquid Cooling System Design, Calculation, and

Explore the application of liquid cooling in energy storage systems, focusing on LiFePO4 batteries, custom heat sink design, thermal management, fire

Get a quote

How Liquid Cooling Systems are Redefining Energy Storage

Conclusion Energy storage liquid cooling systems represent a transformative leap in solving the complex challenges of heat dissipation and safety in high-density energy storage

Get a quote

Electrolyzer Codes and Standards

600 kg of H2 storage at 20 MPa Compressor This presentation does not provide and exhaustive list of codes and standards This presentation does not go into liquid hydrogen codes and

Get a quote

Kehua S³ EStation Liquid-Cooling ESS Showcase: The Largest Energy

The total capacity of the power station is 200MW/400MW, with full adoption of Kehua S³ EStation liquid-cooling ESS solution that features high safety and low LCOE. Integrating the standard

Get a quote

What are the liquid-cooled energy storage power stations?

In liquid-cooled energy storage systems, various liquids can be utilized depending on the specific design and operational requirements of the power station. Common options

Get a quote

Liquid cooling energy storage system standards

Liquid cooling is highly valuablein reducing energy consumption of cooling systems in data centers. We survey the landscape on different deployments of liquid cooling and are helping

Get a quote

Photovoltaic-driven liquid air energy storage system for combined

Renewable energy and energy storage technologies are expected to promote the goal of net zero-energy buildings. This article presents a new sustainable energy solution

Get a quote

Large Scale C&I Liquid and Air cooling energy storage

The EGbatt LiFePo4 energy storage system adopts an integrated outdoor cabinet design, primarily used in commercial and industrial settings. It is highly

Get a quote

Regulatory Standards for Cooling Towers in the United States

Wahaso Outlines the Regulatory Standards for Cooling Towers in the United States Cooling towers are critical components in various commercial and industrial applications, such

Get a quote

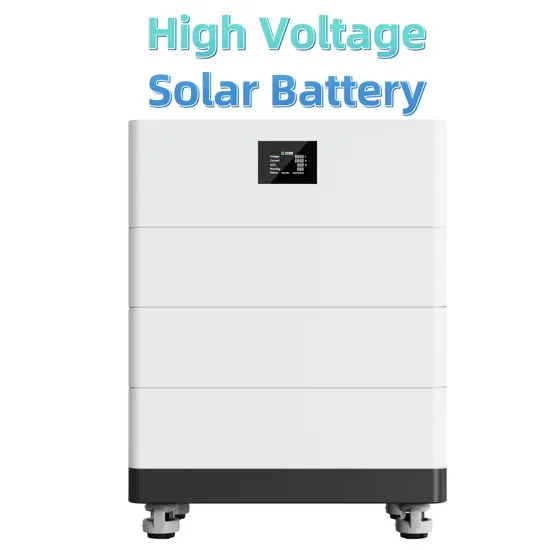

Commercial & Industrial Liquid Cooling Energy Storage System | GSL ENERGY

This system ensures efficient, safe, and long-lasting energy storage with liquid cooling technology, high-voltage lithium iron phosphate (LiFePO4) chemistry, and seamless grid integration.

Get a quote

6 FAQs about [Liquid cooling standards for energy storage power station buildings]

What is a 5MWh liquid-cooling energy storage system?

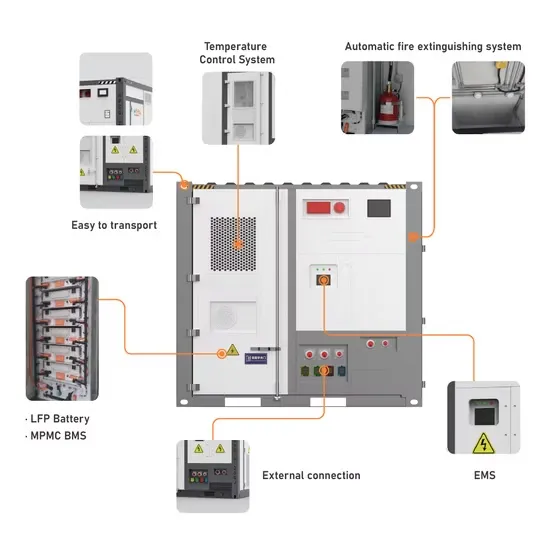

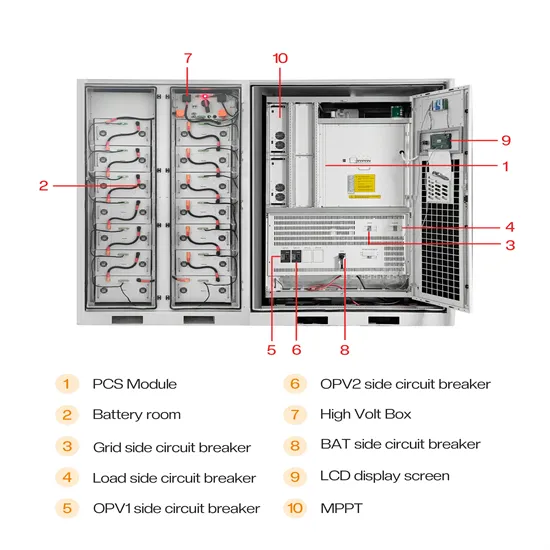

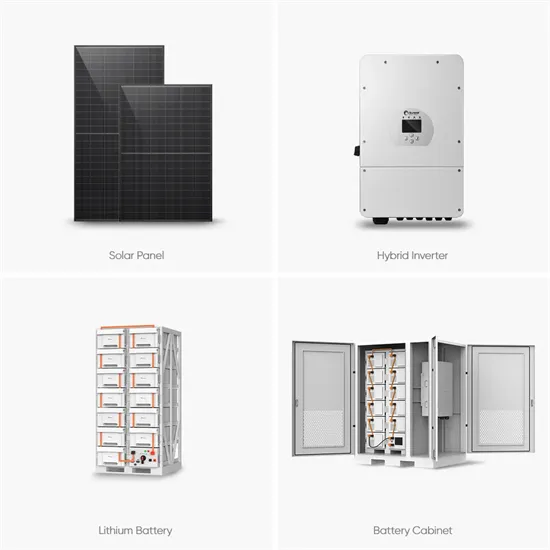

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling unit?

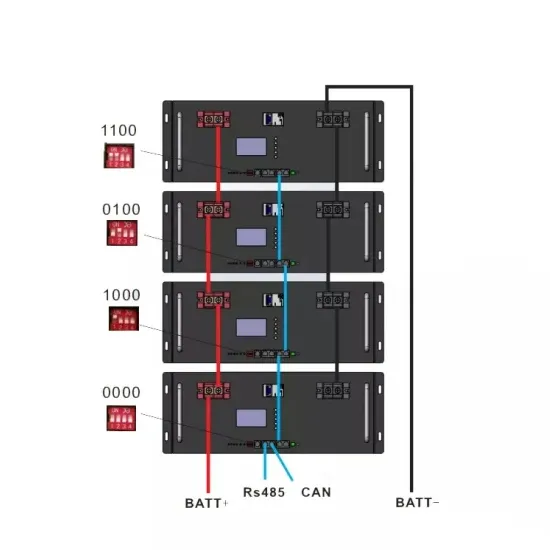

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

How to choose an energy storage unit?

The choice of the unit should be based on the cooling and heating capacity parameters of the energy storage cabin, alongside considerations like installation, cost, and additional functionalities. 3.12.1.2 The unit must utilize a closed, circulating liquid cooling system.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

Guess what you want to know

-

Operation and management of liquid cooling system of energy storage power station

Operation and management of liquid cooling system of energy storage power station

-

Liberia Liquid Flow Energy Storage Power Station

Liberia Liquid Flow Energy Storage Power Station

-

Gabon photovoltaic power station energy storage standards

Gabon photovoltaic power station energy storage standards

-

Does liquid hybrid energy storage power station have commercial value

Does liquid hybrid energy storage power station have commercial value

-

Albania Liquid Flow All-Vanadium Energy Storage Power Station

Albania Liquid Flow All-Vanadium Energy Storage Power Station

-

Energy Storage Liquid Cooling Standards

Energy Storage Liquid Cooling Standards

-

Combination of energy storage power station and wind power

Combination of energy storage power station and wind power

-

Central African Republic photovoltaic power station supporting energy storage

Central African Republic photovoltaic power station supporting energy storage

-

Armenia Energy Storage Power Station Project

Armenia Energy Storage Power Station Project

-

Ghana hybrid energy storage power station

Ghana hybrid energy storage power station

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.