Thermal Management Technology of 1MWh BESS Energy Storage System

The 1MWh Battery Energy Storage System (BESS) is a crucial component in modern energy storage applications. As the capacity and power of BESS increase, thermal

Get a quote

Research on Optimization of Thermal Management System for

Combining simulation analysis and experimental verification, a novel liquid-cooled plate that balances heat dissipation and operational energy consumption is designed.

Get a quote

Research on Optimization of Thermal Management System for Liquid

Combining simulation analysis and experimental verification, a novel liquid-cooled plate that balances heat dissipation and operational energy consumption is designed.

Get a quote

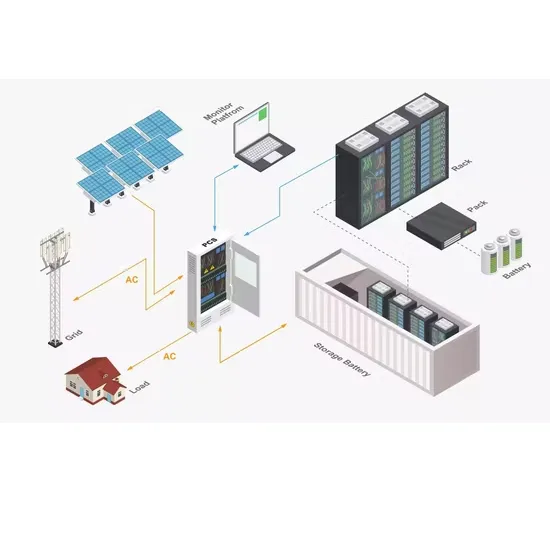

Liquid-Cooled Energy Storage System Architecture

Each liquid-cooled battery pack contains 3-4 times more cells than air-cooled packs. Each management unit monitors the voltage and temperature of 52

Get a quote

Battery Energy Storage

Liquid cooling for battery packs As electricity flows from the charging station through the charging cables and into the vehicle battery cell, internal resistances to the higher currents are

Get a quote

125KW/233KWh Liquid-Cooling Energy Storage Integrated

The energy management system and monitoring system are the core of the coordinated control of the entire system, an important part of the coordinated operation, and an important tool and

Get a quote

Liquid Cooling BESS Container, 5MWH Container Energy Storage System

GSL-BESS-3.72MWH/5MWH Liquid Cooling BESS Container Battery Storage 1MWH-5MWH Container Energy Storage System integrates cutting-edge technologies, including intelligent

Get a quote

How Liquid Cooling is Transforming Battery Energy

Discover how liquid cooling enhances Battery Energy Storage Systems (BESS), improving efficiency, sustainability, and performance for data centers and

Get a quote

Research Progress on Risk Prevention and Control Technology

Liquid cooling technology is a technology that connects energy storage equipment with a liquid cooling system, uses high thermal conductivity liquid such as water and ethanol

Get a quote

Liquid Cooling System Design, Calculation, and Testing for Energy

The lithium battery energy storage system consists of a battery chamber and an electrical chamber. The battery chamber includes the battery pack, liquid cooling system, fire

Get a quote

What does the energy storage power station use to cool down?

Liquid cooling systems signify a cornerstone in thermal management for energy storage installations. These systems employ fluids, typically water or specially formulated

Get a quote

A thermal management system for an energy storage battery

They play an important pivotal role in charging and supplying electricity and have a positive impact on the construction and operation of power systems. The typical types of

Get a quote

High-uniformity liquid-cooling network designing approach for energy

In this work, an approach for rapid and efficient design of the liquid cooling system for the stations was proposed.

Get a quote

Liquid Cooling System Design, Calculation, and Testing for Energy

In this study, a liquid-cooled thermal management system is used for an energy storage project. The design of the energy storage system is detailed, offering valuable insights for related

Get a quote

What is a Liquid Cooling System in BESS?

One of the most effective thermal management solutions in modern BESS design is the liquid cooling system. In this article, we''ll explore what a liquid cooling system is, why it''s

Get a quote

Liquid-cooling Energy Storage SystemsOperation

Liquid-cooling energy storage fire suppression system includes combustible gas detector alarm system, accident ventilation system, automatic fire alarm system, water spray

Get a quote

Liquid Cooling in Energy Storage | EB BLOG

Liquid cooling systems boast superior heat exchange capacities when compared with air cooling, making them more effective at early fire suppression and managing thermal

Get a quote

The World''s First Submerged Liquid Cooled Energy Storage

The official operation of this power station marks the successful application of immersion liquid cooling, a cutting-edge technology, in the field of new energy storage engineering, and plays a

Get a quote

How does a liquid-cooled energy storage power station make

A liquid-cooled energy storage power station is a facility designed to store electrical energy using liquid cooling technologies. This system typically consists of batteries

Get a quote

Why Choose a Liquid Cooling Energy Storage System? | GSL Energy

Liquid cooling systems are suitable for energy storage projects with extremely high thermal management requirements, and the following scenarios are particularly

Get a quote

Liquid Cooled Battery Energy Storage Systems

As the demand for energy storage continues to rise, the technical prowess of liquid-cooled systems is poised to play a transformative role. Their ability to address key

Get a quote

Liquid-Cooled Energy Storage System Architecture and BMS

Each liquid-cooled battery pack contains 3-4 times more cells than air-cooled packs. Each management unit monitors the voltage and temperature of 52 individual cells in real-time and

Get a quote

How liquid-cooled technology unlocks the potential of

The implications of technology choice are particularly stark when comparing traditional air-cooled energy storage systems and liquid-cooled alternatives,

Get a quote

The world''s first submerged liquid cooled energy

The official operation of this power station marks the successful application of immersion liquid cooling, a cutting-edge technology, in the field of new energy

Get a quote

Liquid Cooling System Design, Calculation, and

In this study, a liquid-cooled thermal management system is used for an energy storage project. The design of the energy storage system is detailed, offering

Get a quote

2.5MW/5MWh Liquid-cooling Energy Storage System Technical

The project features a 2.5MW/5MWh energy storage system with a non-walk-in design which facilitates equipment installation and maintenance, while ensuring long-term safe and reliable

Get a quote

Liquid cooling device for energy storage power station

This article provides an overview of industrial and commercial energy storage power stations, focusing on their construction, operation, and maintenance management.

Get a quote

6 FAQs about [Operation and management of liquid cooling system of energy storage power station]

What is a liquid cooling thermal management system?

The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or heating of the coolant through thermal exchange. The coolant transports heat via thermal exchange with the cooling plates and the liquid cooling units.

What is a liquid cooling unit?

The product installs a liquid-cooling unit for thermal management of energy storage battery system. It effectively dissipates excess heat in high-temperature environments while in low temperatures, it preheats the equipment. Such measures ensure that the equipment within the cabin maintains its lifespan.

How are energy storage batteries integrated in a non-walk-in container?

The energy storage batteries are integrated within a non-walk-in container, which ensures convenient onsite installation. The container includes: an energy storage lithium iron phosphate battery system, BMS system, power distribution system, firefighting system, DC bus system, thermal management system, and lighting system, among others.

What is a 5MWh liquid-cooling energy storage system?

The 5MWh liquid-cooling energy storage system comprises cells, BMS, a 20’GP container, thermal management system, firefighting system, bus unit, power distribution unit, wiring harness, and more. And, the container offers a protective capability and serves as a transportable workspace for equipment operation.

What is a liquid cooling system?

This project’s liquid cooling system consists of primary, secondary, and tertiary pipelines, constructed by using factory prefabrication and on-site assembly within the cabin. The primary liquid cooling pipes utilize 304 stainless steel, whereas the secondary and tertiary pipes are made from PA12 nylon tubing.

How does a liquid cooling unit work?

3.12.1.3 The design of the liquid cooling unit must align with the cabin structure, adequately addressing dust prevention needed in the operating environment. The liquid cooling pipeline operates in a closed loop. The coolant, propelled by a pump, circulates through the cold plate, exchanging heat with the batteries, which raises its temperature.

Guess what you want to know

-

Liquid cooling standards for energy storage power station buildings

Liquid cooling standards for energy storage power station buildings

-

Energy Storage Power Station Management Guidelines

Energy Storage Power Station Management Guidelines

-

Cooling method of battery compartment in energy storage power station

Cooling method of battery compartment in energy storage power station

-

Does liquid hybrid energy storage power station have commercial value

Does liquid hybrid energy storage power station have commercial value

-

Botswana Liquid Cooling Energy Storage Management

Botswana Liquid Cooling Energy Storage Management

-

Centralized energy storage power station put into operation in Ghana

Centralized energy storage power station put into operation in Ghana

-

Albania Liquid Flow All-Vanadium Energy Storage Power Station

Albania Liquid Flow All-Vanadium Energy Storage Power Station

-

Wind solar and energy storage power station operation

Wind solar and energy storage power station operation

-

Energy Storage Power Station Design Management

Energy Storage Power Station Design Management

-

Fiji vanadium energy storage power station put into operation

Fiji vanadium energy storage power station put into operation

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.