Lithium Battery Pack Production | Industrialist Wiki

Btw, the Production Template being within tables is breaks the scrolling component and is cursed. The Lithium Battery Pack is a great way to make

Get a quote

MAN celebrates topping-out ceremony for new battery production

From April 2025, the delivered modules will be inserted into battery layers in large series production. These layers will be stacked on top of each other to form the battery pack and then

Get a quote

Battery Pack Manufacturing Process

In this post, you''ll learn the entire battery pack manufacturing process. We''ll cover cell selection, module assembly, safety testing, and future innovations. Whether you''re a

Get a quote

Leading Battery Pack Manufacturers Worldwide: Top 10 List

Explore the top 10 global battery pack manufacturers powering devices from smartphones to EVs, with insights into their innovations and industry impact.

Get a quote

Lithium Batteries: Safety, Handling, and Storage

When making battery packs, always use cells with factory solder tabs. Heat sinks should be used when soldering to the tabs and contact with the solder tabs should be limited to a few seconds.

Get a quote

U.S. Battery Gigafactories [2025 List] | EV Supply

Battery packs are the system-level assemblies that integrate individual cells into modules and packs with the necessary electronics, cooling, and safety

Get a quote

Battery Manufacturing-How We Build Your Custom Battery Packs

Because achieving consistent battery cell quality is critical to reliable lithium ion battery pack assembly. To minimize errors and ensure optimal performance, we employ

Get a quote

Bavaria promotes battery development at MAN

Large-scale production will start at the beginning of 2025. Until then, the battery systems will be manufactured manually in small series – also in Nuremberg. At the time, it was

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

By complying with strict quality control standards and advances in lithium battery technology, battery pack manufacturers can produce high-quality, safe, and reliable battery

Get a quote

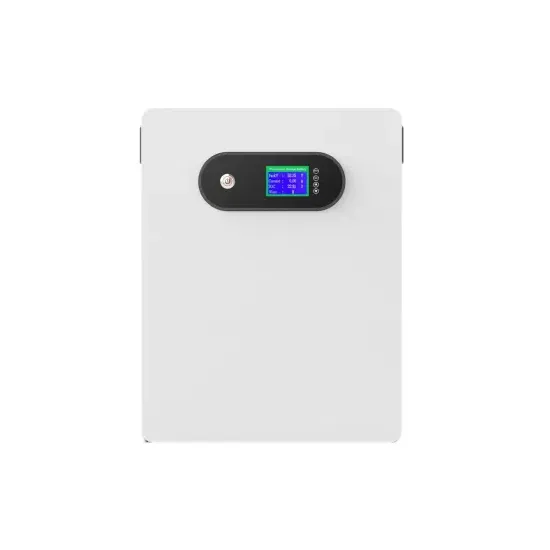

Power Your Home Sustainably with LiFePO4 Battery Pack for

1 day ago· The Ultimate Guide to Home Solar System with LiFePO4 Battery Pack In the era of renewable energy, integrating a home solar system with an efficient home battery is no longer

Get a quote

Bavaria promotes battery development at MAN

Large-scale production will start at the beginning of 2025. Until then, the battery systems will be manufactured manually in small series – also

Get a quote

About

The company is deeply engaged in the field of new energy, has the core technology of the whole industry chain from the core material, battery module to energy storage system, and the

Get a quote

5 Things Battery Pack Manufacturers Must Do for Designing the Factory

Designing an efficient battery pack manufacturing factory requires attention to crucial factors such as proper site selection, stringent safety measures, sustainable practices, advanced

Get a quote

The Best Portable Chargers and Power Banks for 2025

Is your phone, tablet, or laptop typically in the battery red zone before the day''s end? These portable chargers and power banks give you the most boost when you''re out of juice.

Get a quote

Hyundai''s Georgia battery factory faces months-long delay: CEO

9 hours ago· A Hyundai Motor battery plant in Georgia, operated as a joint venture with South Korea''s LG Energy Solution, is facing a startup delay of at least two to three months after a

Get a quote

How to Find the Right Battery Pack Manufacturers for Your Needs

Finding the right battery pack manufacturer is crucial for ensuring that your energy storage solutions meet your specific needs. Factors such as production capacity, quality

Get a quote

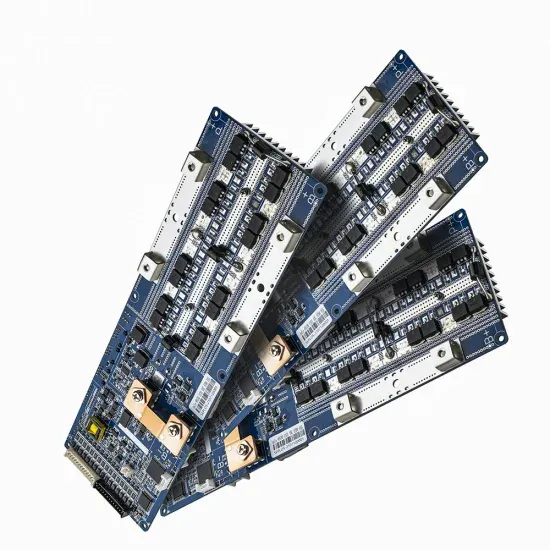

PRODUCTION PROCESS OF BATTERY MODULES AND

VDMA The VDMA represents more than 3,700 German and European mechanical and plant engineering companies. The Battery Production specialist department is the point of contact

Get a quote

5 Things Battery Pack Manufacturers Must Do for

Designing an efficient battery pack manufacturing factory requires attention to crucial factors such as proper site selection, stringent safety measures,

Get a quote

GM Original Equipment Battery Ratings

GM Original Equipment Battery Ratings Refer to the Electronic Parts Catalog for additional replacement battery information and fleet vehicle information.

Get a quote

"It''s the start of something big"

From 2025, MAN will manufacture its own battery packs in a mass production facility in Nuremberg. The foundation stone for this key future project was laid on 10 October.

Get a quote

Lifepo4 Battery Pack Factory

Seastar Battery, a top LiFePO4 battery manufacturer in China, provides high-quality lithium batteries globally. We offer both standard and custom solutions,

Get a quote

Battery Manufacturing-How We Build Your Custom

Because achieving consistent battery cell quality is critical to reliable lithium ion battery pack assembly. To minimize errors and ensure

Get a quote

Optimal Lithium Battery Charging: A Definitive Guide

Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Get a quote

6 FAQs about [Pack battery factory recommendation]

How do you choose a battery pack manufacturer?

When choosing a battery pack manufacturer, look at the company’s reputation and product quality. Check their innovation and customization options. Also, consider their customer service. Evaluate their commitment to sustainability and their ability to meet your needs. What are the benefits of lithium iron phosphate (LiFePO4) batteries?

What is the battery pack manufacturing process?

The battery pack manufacturing process involves cell selection, module assembly, wiring, thermal management, and safety integration. Each step ensures efficiency, reliability, and durability. Understanding this process helps manufacturers optimize production, clients get tailored solutions, and consumers receive safer, longer-lasting batteries.

What is a battery pack?

A battery pack is a set of identical batteries or individual battery cells. It can be configured in series, parallel, or a combination to deliver the desired voltage, capacity, or power density. Battery packs provide the necessary energy to power various electronic devices and systems. Part 3. Top 10 battery pack manufacturers’ reviews 1.

What makes a good battery pack?

The foundation of any high-performance battery pack begins with selecting the right battery cells. This critical decision influences the overall performance, lifespan, safety, and cost of the final battery pack. Different applications require specific types of battery cells based on their unique characteristics:

What are the final stages of the battery pack manufacturing process?

The final stages of the battery pack manufacturing process involve careful handling, transportation, and implementation to ensure products reach their destination safely and function as intended. Battery packs require specialized packaging to prevent damage: Each shipment contains essential information:

How is Industry 4.0 transforming battery pack manufacturing?

Manufacturing innovations are revolutionizing production efficiency: Industry 4.0 integration enables real-time monitoring and adaptive process control throughout battery pack assembly, significantly reducing defect rates while improving traceability. Emerging technologies will transform battery pack manufacturing:

Guess what you want to know

-

Pack lithium battery factory design

Pack lithium battery factory design

-

Pack Battery Factory Introduction

Pack Battery Factory Introduction

-

Cote d Ivoire pack lithium battery factory

Cote d Ivoire pack lithium battery factory

-

Togo pack battery factory

Togo pack battery factory

-

Swiss quality lithium battery pack factory price

Swiss quality lithium battery pack factory price

-

Selling pack lithium battery factory

Selling pack lithium battery factory

-

Pack lithium battery factory need

Pack lithium battery factory need

-

San Marino pack battery factory

San Marino pack battery factory

-

Aluminum Cube Pack Battery Factory

Aluminum Cube Pack Battery Factory

-

Timor-Leste lithium battery pack 200ah

Timor-Leste lithium battery pack 200ah

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.