Here are the 4 Top Considerations in Lithium-Ion

Lithium-ion battery manufacturing demands the most stringent humidity control and the first challenge is to create and maintain these ultra

Get a quote

EV Lithium Battery PACK Design Process from Manufacturers

At Bonnen Battery, our engineering team follows a systematic approach to battery pack design, ensuring optimal performance and safety for various EV applications. This blog

Get a quote

Lithium-ion Battery Pack Manufacturing Process & Design

This guide discussed the lithium battery pack anufacturing process, battery pack design, and the impact of technological advancements.

Get a quote

Lithium Ion Battery Pack factory

China Lithium Ion Battery Pack manufacturer, Shenzhen BAK Technology Co., Ltd. is Li Polymer Battery Pack factory, offering quality products at factory prices.

Get a quote

How are Lithium-ion Battery Packs Manufactured?

These compact powerhouses drive our modern world, from portable gadgets to renewable energy storage. But how exactly are they made? Lithium-ion battery packs are manufactured through

Get a quote

EM3ev-Custom Lithium Battery Pack Solutions

EM3ev offers custom lithium battery packs for e-bikes and energy storage. Known for reliability and long lifespan, contact EM3ev for Solutions

Get a quote

Battery Factory How to Build the Lithium-Ion Battery

Lithium-ion battery pack suppliers like Ufine have their pack structure design, pack electronic design, and pack production workshop and

Get a quote

Handbook On Lithium Battery Pack Design

The second type of rechargeable lithium battery is called a lithium ion battery, which has a negative terminal that consists of a carbon-based material, usually graphite, or another type of

Get a quote

DOE ESHB Chapter 3: Lithium-Ion Batteries

Abstract Lithium-ion batteries are the dominant electrochemical grid energy storage technology because of their extensive development history in consumer products and electric vehicles.

Get a quote

Lithium Battery Module Pack Assembly Line

A Lithium Battery Module PACK Assembly Line is a production line designed to assemble individual lithium battery cells into modules and then further assemble these modules into

Get a quote

Battery Pack Designer''s Guide: From Beginner to Pro [With

Battery pack design requires understanding both fundamental electrochemistry and application-specific engineering requirements. Custom battery pack applications have expanded

Get a quote

Lithium Battery Cell & Pack Manufacturer In China | Keheng

Keheng can provide you with product design drawings within 1 week and samples within 3 weeks. Keheng owns battery cell factory and battery pack factory, dedicate to offer one-stop solutions

Get a quote

EV Lithium Battery PACK Design Process from

At Bonnen Battery, our engineering team follows a systematic approach to battery pack design, ensuring optimal performance and safety for

Get a quote

Design approaches for Li-ion battery packs: A review

The final discussion analyzes the correlation between the changes in the design methods and the increasing demand for battery packs. The outcome of this paper allows the

Get a quote

Complete Guide to Lithium Battery Pack Design and Assembly

A lithium battery pack is not just a simple assembly of batteries. It is a highly integrated and precise system project. It covers multiple steps, including cell selection,

Get a quote

Top 12 Lithium Ion Battery Manufacturers in the UK

Discover the top 12 Lithium Ion battery manufacturers in the UK. Choose from industry-leading companies for quality products and cutting-edge technology.

Get a quote

High-Performance Custom Battery Packs & Energy

This strategic partnership creates a fully integrated capability, from cell development through to... For custom battery pack design, custom battery

Get a quote

Key Points of Lithium Battery PACK Manufacturing

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium

Get a quote

Battery Factory How to Build the Lithium-Ion Battery Pack?

Lithium-ion battery pack suppliers like Ufine have their pack structure design, pack electronic design, and pack production workshop and can carry out independent development

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

From selecting and matching battery cells to assembling, testing, and packaging, discover the key steps involved in creating high-quality lithium-ion battery packs. Learn about

Get a quote

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

Get a quote

Lithium Battery Pack Designer

About Our Battery Pack Designer Our battery pack designer tool is a web-based application that helps engineers and DIYers build custom DIY battery packs various electronic devices or

Get a quote

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide In recent years, the demand for efficient and powerful energy storage solutions has surged, primarily driven by

Get a quote

6 FAQs about [Pack lithium battery factory design]

What makes a custom lithium-ion battery pack unique?

The foundation of any custom lithium-ion battery pack lies in the selection of the integrated cells. Our cell selection for custom packs involves: Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities.

What are the basic components of a lithium-ion battery pack?

Before diving into the design process, it's crucial to understand the fundamental components of a lithium-ion battery pack: Cells: The basic building blocks of a battery pack. Lithium-ion cells come in various shapes (cylindrical, prismatic, pouch) and chemistries (e.g., NMC, LFP).

How do you make custom lithium-ion battery packs?

Key Takeaway: Manufacturing custom lithium-ion battery packs requires precise engineering, quality control, and safety standards. The process involves gathering requirements, selecting cells, concurrent engineering, prototyping, certification, production planning, and lifecycle support.

What is a lithium ion battery pack?

A battery pack consists of multiple cells connected in series or parallel. How to make lithium-ion batteries? It’s always been an interesting topic. The production of lithium-ion batteries is a complex process, totaling Three steps. The cell sorting stage is a critical step in ensuring the consistent performance of lithium-ion batteries.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

How can lithium-ion cell technology improve a custom pack design?

Lithium-ion cell advancements continue expanding performance boundaries yearly. Leveraging state-of-the-art cell technology is crucial for maximizing custom pack capabilities. Concurrent electrical and mechanical engineering is needed to optimize the custom pack design within constraints.

Guess what you want to know

-

Pack lithium battery factory customization

Pack lithium battery factory customization

-

Tajikistan professional lithium battery pack factory price

Tajikistan professional lithium battery pack factory price

-

Cote d Ivoire pack lithium battery factory

Cote d Ivoire pack lithium battery factory

-

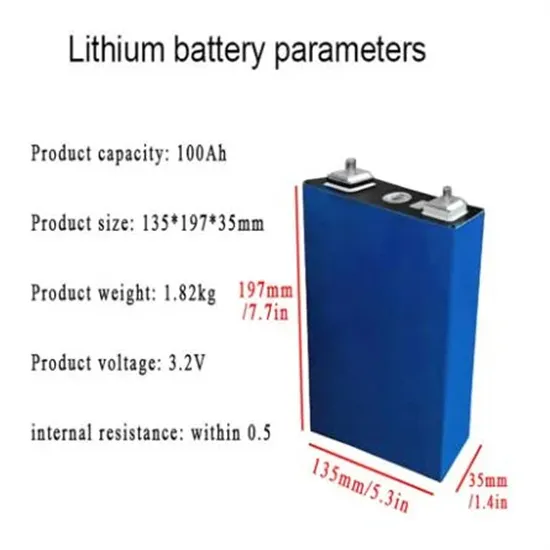

Lithium battery pack factory voltage

Lithium battery pack factory voltage

-

Lithium battery pack design price

Lithium battery pack design price

-

4 series 7 lithium battery pack

4 series 7 lithium battery pack

-

Lithium battery pack module

Lithium battery pack module

-

Ireland pack battery factory

Ireland pack battery factory

-

Which lithium battery pack is better in Nicaragua

Which lithium battery pack is better in Nicaragua

-

Which lithium battery pack is better in Kuwait

Which lithium battery pack is better in Kuwait

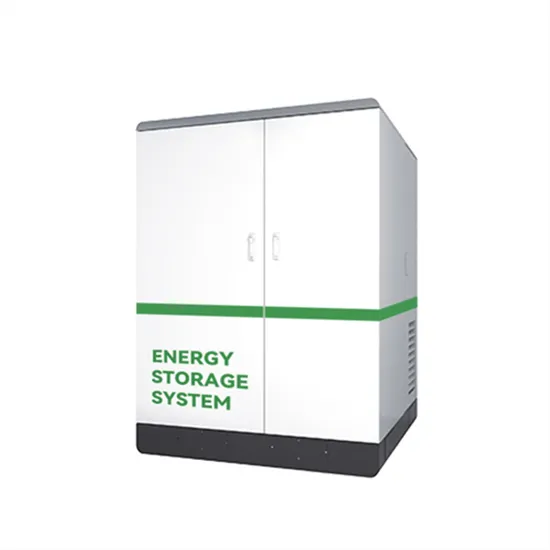

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

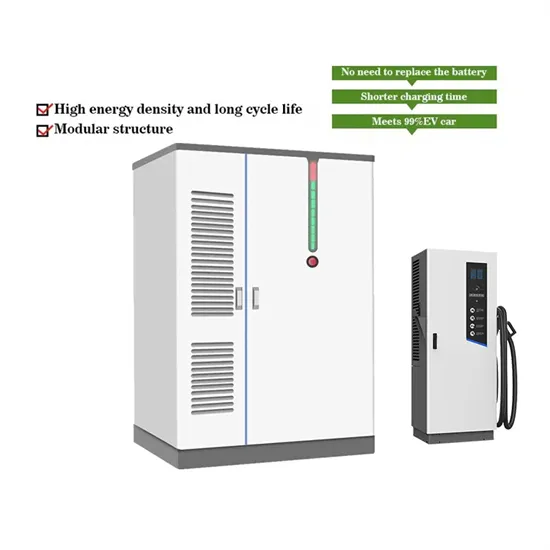

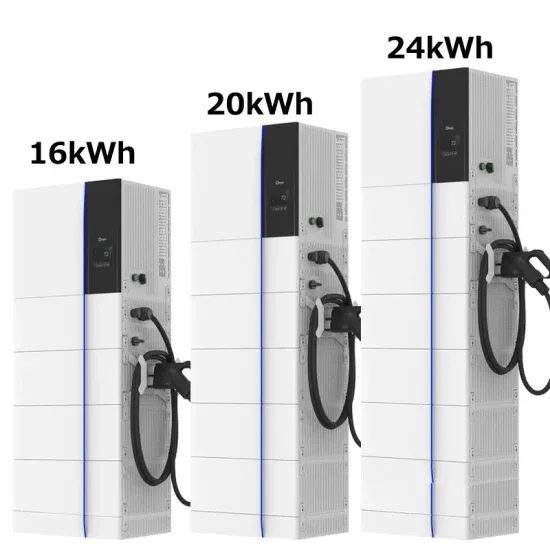

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.