Battery Cells vs. Modules vs. Packs: How to Tell the Difference

Learn the differences between battery cells, modules, and packs. See how each layer works, why BMS and thermal systems matter, and where these components fit in EVs and energy storage.

Get a quote

What is a Lithium-Ion Battery Module? (Lithium-Ion

They are lighter, have a higher energy density, and can be discharged and recharged more times of a rechargeable battery than lead

Get a quote

Battery Cell, Module, Pack, what`s the Difference?

A battery pack is a higher-level energy storage unit than a battery module. Multiple battery modules are connected in series and parallel through carefully designed busbar

Get a quote

Battery Cell, Module or Pack. What''s the difference? [Infographics]

Battery cell production is primarily a chemical process, while module and pack production is a mechanical assembly process. Batteries are sometimes called Cells, Modules

Get a quote

What Are Battery Cells, Battery Modules, And Battery

The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in

Get a quote

Battery Cell VS Battery Module VS Battery Pack

Understanding the differences between battery cells, modules, and packs is essential for designing efficient energy storage systems. This article examines their construction,

Get a quote

Lithium-ion Battery Module and Pack Production Line

The lithium-ion battery module and pack line is a key component in the field of modern battery technology. Its high degree of automation and

Get a quote

The Fundamentals of Battery Pack and Module Testing

When configured as an EV battery cycler, it is designed for battery cycling (charging and discharging) of packs and/or modules and can provide

Get a quote

Introduction to Electric Vehicle Battery Modules and Packs

EV battery cell, module and pack: key differences You may have heard various terms related to EV battery design, but perhaps thought them to refer to a single unit, when they really refer to

Get a quote

How to Assemble a Lithium-Ion Battery Pack with a

Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get a quote

What is a Lithium-Ion Battery Module? (Lithium-Ion Battery Uses)

They are lighter, have a higher energy density, and can be discharged and recharged more times of a rechargeable battery than lead-acid batteries. Lithium-ion battery

Get a quote

Battery Cell, Module or Pack. What''s the difference?

Battery cell production is primarily a chemical process, while module and pack production is a mechanical assembly process. Batteries are

Get a quote

PRODUCTION PROCESS OF BATTERY MODULES AND

, this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several modules

Get a quote

Battery Cell, Module, or Pack: What''s the difference?

What is a battery module? It''s a group of connected battery cells, boosting voltage and capacity. It''s the middleman between single cells and the entire battery pack.

Get a quote

Sturcture of Battery: From Cell to Module and Pack

To review a battery''s structure from a macro-view as a whole pack until the smallest units, which are referred to as battery cells, batteries are by

Get a quote

What Is A Lithium-Ion Battery Cell, Module, and Pack | Grepow

A lithium-ion battery pack is the largest and most complex assembly in the hierarchy of battery systems. It consists of multiple modules arranged in a specific

Get a quote

Battery Cell Module Pack: Everything You Need to Know

Modules are made up of multiple cells that work together to improve capacity and voltage. Packs are full assemblies that include modules, BMS, and other parts that are needed

Get a quote

18650 Lithium Battery Charger Module Charging BMS

Amazon : 18650 Lithium Battery Charger Module Charging BMS Board Kits with Dual Protection Function TP4056 Type-C Input Interface

Get a quote

Design approaches for Li-ion battery packs: A review

There is a great interest in the literature about PCM in Li-ion battery packs because the capacity of a Li-ion battery module with PCM can be safely and fully utilized even

Get a quote

What Are Battery Cells, Battery Modules, And Battery Packs?

The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in series and parallel. The production

Get a quote

(2-Pack) 7.4V Li-ion 2200mAh Rechargeable Battery

(2-Pack) 7.4V Li-ion 2200mAh Rechargeable Battery Module with PCB 18650 * 2 Bare Leads for DIY, Medical Equipments, LED Light Kit, RC

Get a quote

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

The industry has adapted a more functional nomenclature for battery packs; it generally refers to the module size by the number of cell strings in series and parallel and pack with number of

Get a quote

The Fundamentals of Battery Module and Pack Test

Battery pack and module testing is more critical than ever. Today''s engineers face new challenges including increased complexity of the tests and set-ups, long development and test

Get a quote

Battery Cell Module Pack: Everything You Need to Know

Modules are made up of multiple cells that work together to improve capacity and voltage. Packs are full assemblies that include modules,

Get a quote

Key Points of Lithium Battery PACK Manufacturing Process

Conclusion The lithium-ion battery pack manufacturing process involves selecting and matching battery cells, assembling the pack with a protective circuit module (PCM) or

Get a quote

Battery Cell VS Battery Module VS Battery Pack

Understanding the differences between battery cells, modules, and packs is essential for designing efficient energy storage systems. This article examines

Get a quote

6 FAQs about [Lithium battery pack module]

What is a battery cell module pack?

While the terms “battery cell,” “battery module,” and “battery pack” are often used interchangeably, the battery cell module pack refers to different stages of the battery’s construction. Battery cells are the basic electrochemical units. Modules are made up of multiple cells that work together to improve capacity and voltage.

What is a lithium-ion battery pack?

A lithium-ion battery pack is the largest and most complex assembly in the hierarchy of battery systems. It consists of multiple modules arranged in a specific configuration to meet the voltage and energy requirements of a particular application.

What is a modular battery pack?

A modular battery pack takes the concept of modularity to the next level by incorporating interchangeable and stackable battery modules. Each module contains a set number of battery cells, and these modules can be added or removed as needed to adjust the pack's capacity or voltage.

What is the difference between battery cell production and module & pack production?

Battery cell production is primarily a chemical process, while module and pack production is a mechanical assembly process. Batteries are sometimes called Cells, Modules or Packs. But what does that mean? What is the difference? Battery cells are containers that chemically store energy.

What is the structure of a lithium battery?

The general structure of lithium batteries is a cell, battery module and battery pack. Battery cell technology is the cornerstone of battery systems. The process of assembling lithium battery cells into groups is called PACK, which can be a single battery or a battery module connected in series and parallel.

What are the parts of a battery pack?

1. Basic Unit of A Battery Pack: Battery Cells 2. A Unit Assembled from Multiple Battery Cells: Battery Modules 3. The Complete Package: Battery Packs 4. Battery Cell vs Battery Module vs Battery Pack: Key Differences

Guess what you want to know

-

Lithium battery pack buck output module

Lithium battery pack buck output module

-

30Ah lithium battery pack

30Ah lithium battery pack

-

Egypt 72v lithium battery pack

Egypt 72v lithium battery pack

-

5v lithium battery pack with large capacity

5v lithium battery pack with large capacity

-

Cambodia lithium battery pack supplier company

Cambodia lithium battery pack supplier company

-

Thailand lithium battery energy storage module

Thailand lithium battery energy storage module

-

Cote d Ivoire pack lithium battery factory

Cote d Ivoire pack lithium battery factory

-

Waterproof lithium iron phosphate battery pack

Waterproof lithium iron phosphate battery pack

-

Huawei s lithium battery pack layout

Huawei s lithium battery pack layout

-

6 series 4 parallel 24v lithium battery pack

6 series 4 parallel 24v lithium battery pack

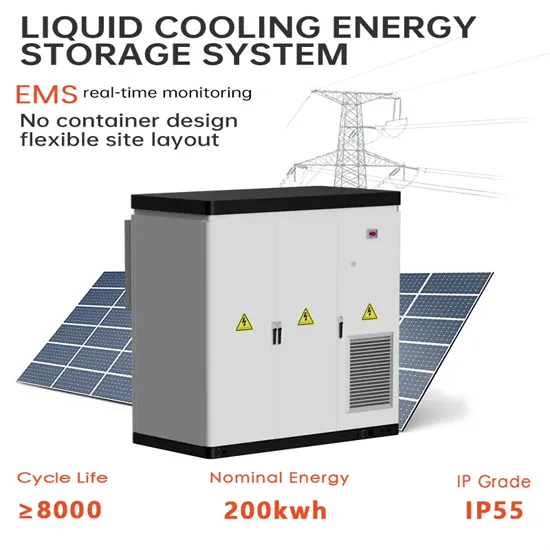

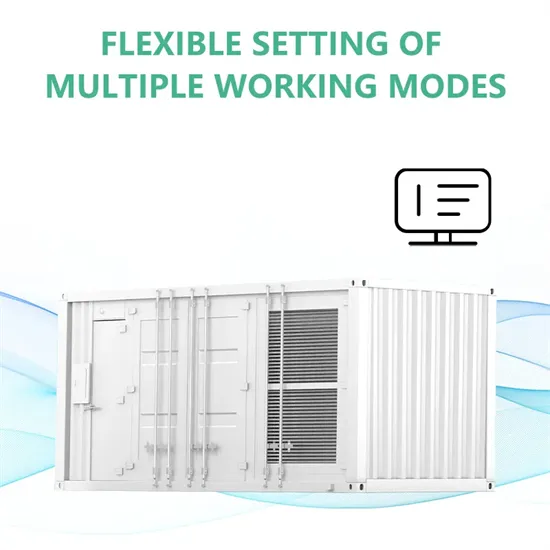

Industrial & Commercial Energy Storage Market Growth

The global industrial and commercial energy storage market is experiencing unprecedented growth, with demand increasing by over 350% in the past three years. Energy storage cabinets and lithium battery solutions now account for approximately 40% of all new commercial energy installations worldwide. North America leads with a 38% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 25-30%. Europe follows with a 32% market share, where standardized energy storage cabinet designs have cut installation timelines by 55% compared to custom solutions. Asia-Pacific represents the fastest-growing region at a 45% CAGR, with manufacturing innovations reducing system prices by 18% annually. Emerging markets are adopting commercial energy storage for peak shaving and energy cost reduction, with typical payback periods of 3-5 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $450/kWh for complete energy solutions.

Energy Storage Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving energy storage cabinet and lithium battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 45% less energy loss, extending battery lifespan to 18+ years. Standardized plug-and-play designs have reduced installation costs from $900/kW to $500/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 35% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 25% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $400/kWh for incremental storage. These innovations have significantly improved ROI, with commercial projects typically achieving payback in 4-6 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $22,000 and premium systems (200-500kWh) from $90,000, with flexible financing options available for businesses.